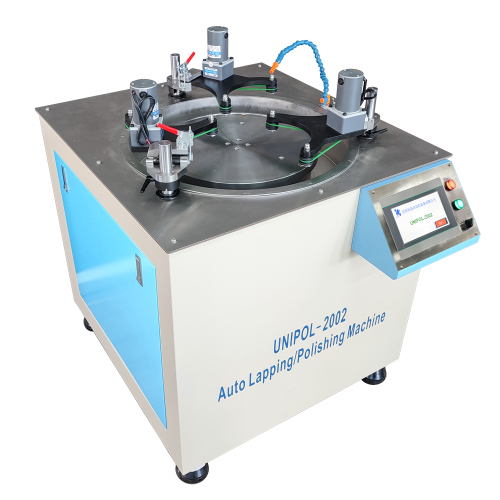

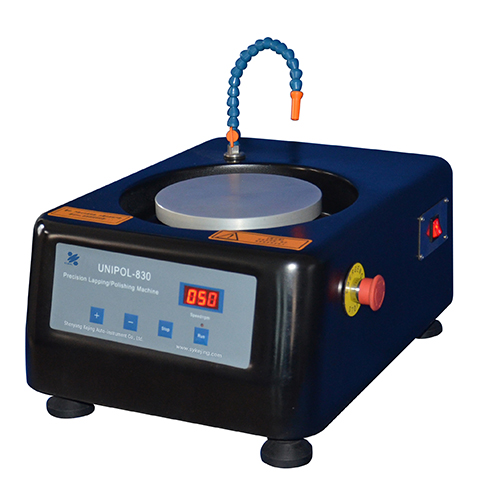

Precision Automatic Lapping Polishing Machine

Brand Shenyang Kejing

Product origin Shenyang, China

Delivery time 10 working days

Supply capacity 50 sets

1. The automatic polishing machine is equipped with three processing stations, which supports processing multiple samples at the same time and improves processing efficiency.

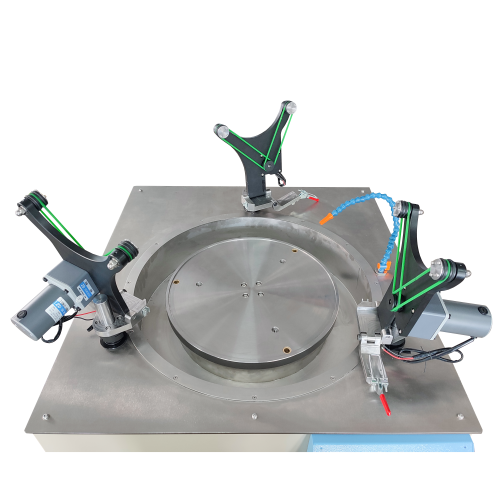

2. The stations of the automatic polishing machine have the function of swinging left and right to ensure that the surface of the sample is evenly polished and polished. The automatic polishing machine can avoid surface irregularities.

3. The automatic polishing machine supports the use of grinding discs with abrasives or polishing discs with sandpaper, which is flexible to operate.

Introduction of automatic polishing machine:

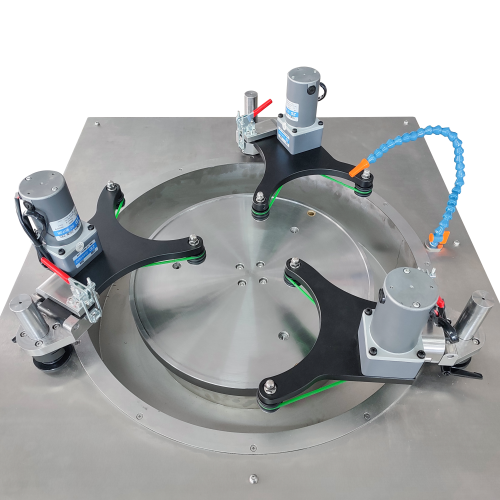

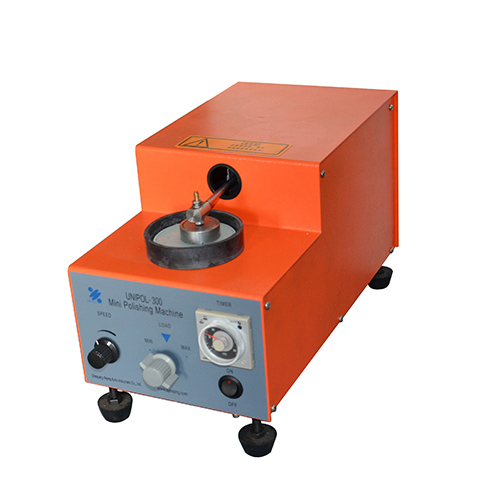

UNIPOL-2002 auto lapping polishing machine has three processing stations. It is a floor-standing polishing machine that can grind and polish large-size samples. Auto lapping polishing machine can be used for grinding and polishing samples of crystals, ceramics, metals, glass, rock samples, mineral samples, PCB boards, infrared optical materials (such as zinc selenide, zinc sulfide, silicon, germanium and other crystals), refractory materials, composite materials and other materials. Auto lapping polishing machine is one of the ideal grinding and polishing equipment for scientific research and production experiments.The precision polishing machine is equipped with a Ø508mm grinding and polishing disc and three processing stations. The precision polishing machine can be used to grind and polish discs ≤Ø160mm or rectangular surfaces with a diagonal length of ≤160mm. During the grinding process, the three processing stations of the precision polishing machine can swing left and right at a certain frequency, while driving the carrier block to swing left and right. The carrier block rotates while revolving with the grinding disc. The precision polishing machine can make the sample move irregularly, so that the surface quality of the sample after grinding is uniform. The three swing arms have their own drive motors to drive the carrier plate to rotate. The carrier block equipped with the polishing machine with three work stations is a precision cylindrical metal block with high flatness and parallelism, so that the surface of the sample after grinding also has high flatness, and the polishing machine with three work stations will not chamfer the edge of the sample, which is especially suitable for samples with high edge requirements. If the three station ample polishing machine is equipped with appropriate accessories (GPC series precision grinding and polishing controller), it can mass-produce high-quality surface grinding and polishing products, such as grinding and polishing of wafer samples with a diameter of ≤Ø160mm. The sample can be ground by grinding disc plus abrasive, or by polishing disc with sandpaper. The sandpaper or polishing pad is clamped by magnetic adsorption, which is convenient for loading and unloading. The specific choice of sandpaper grinding or abrasive grinding can be selected according to the material of the sample to be ground.

Advantages of precision polishing machine:

1. The auto lapping polishing machine is used with a precision cylindrical metal carrier block to ensure high flatness and parallelism of the sample surface after grinding.

2. The auto lapping polishing machine is used with the GPC series precision grinding and polishing controller to achieve mass production of high-quality surface grinding and polishing products.

3. The sandpaper or polishing pad of the auto lapping polishing machine is clamped by magnetic adsorption, which is easy to load and unload.

Technical parameters of polishing machine with three work stations:

| Product name | UNIPOL-2002 Auto lapping polishing Machin | |

| Product model | UNIPOL-2002 | |

| Main parameters | 1. Grinding disc of three station ample polishing machine: diameter φ508mm (20 inches) (grinding disc is not included in the standard configuration, please consult sales for specific materials). | |

| 2. Sample carrier of three station ample polishing machine: diameter φ160mm (6 inches), thickness 35mm. | ||

| 3. Repairing ring of three station ample polishing machine: outer diameter φ196mm, inner diameter φ160.5mm, thickness 36mm. | ||

| 4. Swing arm bracket of polishing machine with three work stations: 1 set every 120°, a total of 3. | ||

| 5. Number of workstations: 3. | ||

| 6. Grinding disc speed: number of revolutions: 10-90 rpm. | ||

| 7. Swing arm bracket swing speed gear: 15-30 gears (reference speed: 5.5-13.5 times/minute), the swing arm can be flipped up and folded, which is convenient for cleaning the grinding disc and replacing the sample carrier. | ||

| 8. Speed of driving wheel on swing arm: 30-90rpm. | ||

| 9. Power of single motor of driving wheel on swing arm: 25W. | ||

| 10. Main motor of grinding machine: variable frequency motor: 1.25kW, 220V. | ||

11. Specifications of automatic polishing machine: Size: floor-standing, 820*1060*945mm. Weight: 450kg. |  | |

Optional accessories for precision polishing machine:

| NO. | Name | Function category | Picture |

| 1 | SKZD-2 dripper | (optional) |  |

| 2 | SKZD-3 dripper | (optional) |  |

| 3 | φ508mm cast iron grinding disc | (optional) |  |

| 4 | φ508mm cast aluminum disc | (optional) |  |

| 5 | φ508mm glass disc | (optional) | |

| 6 | φ508mm polishing pad | (optional) |  |

| 7 | Custom wax-free polishing disc (size: can be customized according to customer requirements) | (optional) |  |

About us:

We not only provide equipment, but also provide all-round support for scientific research projects. With innovative scientific and technological strength, we actively serve the society, always take customer needs as the core, and focus on creating the best solutions for customers. We pursue excellence and aim to become a leading brand in the field of domestic material analysis instruments and win trust and respect in the global market. Choosing Shenyang Kejing, you will have a dynamic, innovative partner who will move forward with you.