Dual 8" Platens Grinder And Polisher

1. The dual platens lapping and polishing machine is not only suitable for grinding and polishing metal materials, but also for ceramics, glass and various organic polymer materials.

2. The dual platens lapping and polishing machine is equipped with a double grinding disc structure, which can perform grinding and polishing operations on different samples at the same time to avoid mutual contamination.

3. Thedual platens lapping and polishing machine uses magnetic adsorption to fix sandpaper and polishing pads, which effectively avoids the problem of polishing fabric pleating caused by traditional clamping methods.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

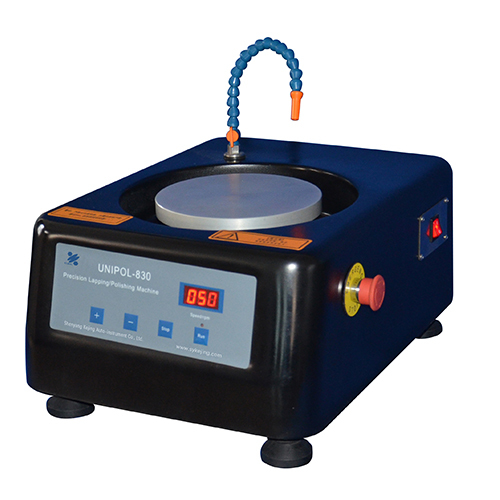

Introduction of metallographic grinding and polishing machine:

UNIPOL-820 dual platens polishing machines with magnetic is mainly used for grinding and polishing of metal materials, and also for grinding and polishing of other non-metallic materials, such as ceramics, glass, PCB boards, rock samples, mineral samples, infrared optical materials (such as zinc selenide, zinc sulfide, silicon, germanium and other crystals), refractory materials, composite materials and organic polymer materials. Dual platens polishing machines with magnetic can choose to place sandpaper and polishing pads by pressing ring clamping or magnetic adsorption, which makes the operation more stable. Magnetic adsorption is mainly to overcome the shortcomings of pleating of traditional clamping polishing fabrics. The polishing fabric with pressure-sensitive adhesive is pasted on the grinding and polishing film, and then adsorbed on the magnetic sheet; secondly, the replacement of sandpaper and polishing pads of dual platens polishing machines with magnetic is more convenient. The metallographic grinding and polishing machine adopts a double grinding disc structure, which can be opened at the same time or individually, and can grind and polish different samples at the same time without contamination.

Main features of metallographic grinding and polishing machine:

1. Precise rotation, low noise

2. Double disc structure, more convenient for use

3. Digital display speed

4. Dual platens lapping and polishing machine can be equipped with an automatic slurry feeder or a circulating pump.

Technical parameters:

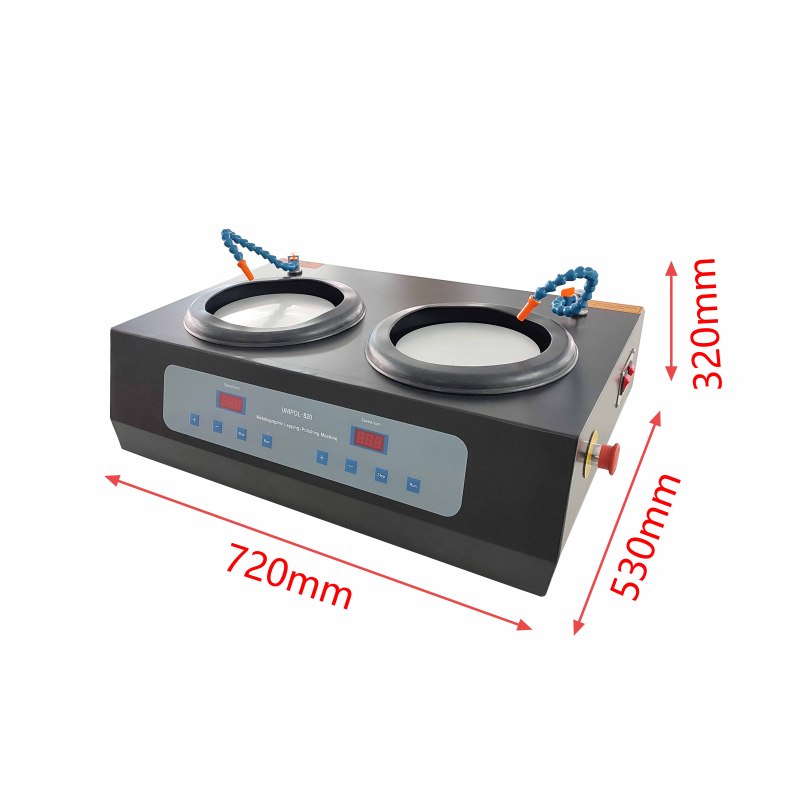

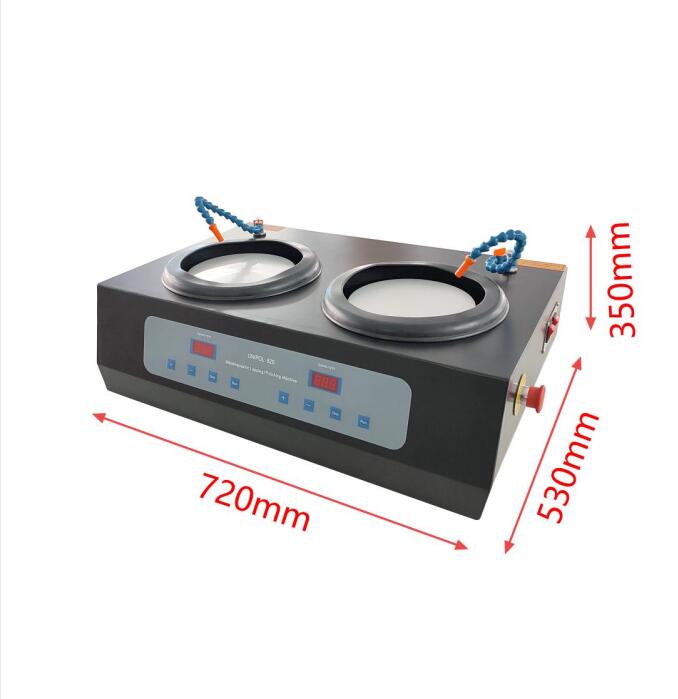

Product Name | UNIPOL-820 Metallographic Grinding and Polishing Machine / Lapping Machine |

Product Model | UNIPOL-820 |

Installation Conditions | 1. Temperature and humidity: 10-85%RH (at 25℃ without condensation) Temperature: 0-45℃. 2. There is no strong vibration source and corrosive gas around the equipment. 3. Power supply: Export standard equipment: AC110/230V 50/60Hz three-pole socket 10A. Domestic standard equipment: AC220V 50Hz national standard three-pole socket 10A (the socket must have a good safety protection grounding wire). 4. Cooling water: The equipment is equipped with a water inlet and a water outlet, and you need to connect the tap water and drainage pipelines by yourself. 5. Air source: no requirement for standard equipment. 6. Workbench: It is recommended to use it on an operating table or desktop with a load-bearing capacity of more than 100kg. 7. Ventilation device: good ventilation environment, no special ventilation device requirements. 8. Auxiliary equipment (need to be purchased separately): Recommended: 1. SKCH-1 precision thickness gauge. 2. SZKD-2 automatic stirring dripper, SKZD-3 suspension dripper. 3. SKCS-1 blow dryer. |

Main Parameters (Specification) | 1. Equipment power supply port: AC110/220V conversion (domestic AC110V is invalid). 2. Total power: 360W. 3. Grinding and polishing disc diameter: Φ203 mm. 4. Grinding and polishing disc speed: 50-600rpm (adjustable). 5. Polishing disc station: 2 stations. 6. Spindle drive motor: DC110V 165W. 7. Control mode: single-chip microcomputer + button. Remarks: 1. The equipment power supply is divided into export and domestic power supply. The actual power supply parameters are subject to the label attached to the back of the product. 2. Various grinding and polishing discs, special fixtures, special parts, etc. can be customized according to user requirements. |

Product Dimension And Weight | 8. Product specifications: Dimensions: L720×W530×H320mm. Net weight: ≈44Kg.

|

Standard Accessories:

No. | Name | Qty | Picture |

1 | Magnetic Sheet | 4 pcs |

|

2 | (Steel) Lapping Buffer Sheet | 5 cs |

|

3 | Sandpaper | 2 pcs each |

|

4 | Polishing Pad (Nubuck leather, synthetic leather,) | 1 pcs each |   |

5 | Diamond Polishing Paste (W2.5) | 1 pcs |

|

Optional accessories:

No. | Name | Functional type | Picture |

1 | UNIPOL-01 Type TEM Wedge Grinding and Polishing Fixture | (optional) |

|

Warranty:

One year limited with lifetime support (not including rusted parts due to inadequate storage conditions).

Logistics:

About us:

We have won the trust of customers around the world with our excellent product quality and spirit of continuous innovation. We are well aware that the performance of a product depends not only on design and manufacturing, but also on subsequent maintenance. To this end, we not only provide high-quality equipment, but also provide customers with detailed user guides and maintenance manuals to help customers better use and maintain the equipment and extend the service life of the equipment.