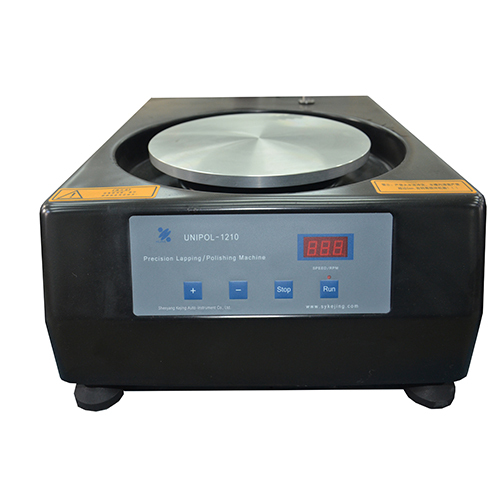

Heavy Duty (12") Precision Grinding And Polishing Machine

1. Heavy duty precision polishing machine can achieve high-quality polishing effects by precisely processing different hardness and material properties.

2. Heavy duty precision polishing machine provides a larger working surface and can process larger samples at a time. Sample polishing machines can improve work efficiency and accuracy.

3. Heavy duty precision polishing machine has a multi-purpose design and can perform fine processing on various types of materials. Sample polishing machines are suitable for a variety of scenarios from laboratory research to industrial production.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Introduction of sample polishing machines:

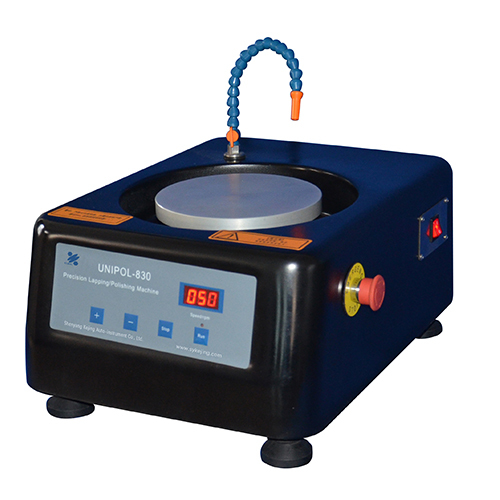

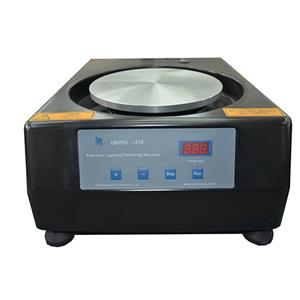

UNIPOL-1210 metallographic sample polishing machines is a manual grinding and polishing machine designed and developed by our company mainly for various universities, research institutes and metallographic laboratories. Sample polishing machines are mainly used for grinding and polishing various metallographic samples, and can also grind and polish other types of non-metallic materials, such as ceramics, glass, PCB boards, infrared optical materials (such as zinc selenide, zinc sulfide, silicon, germanium and other crystals), rock samples, mineral samples, refractory materials, composite materials and organic polymer materials. Sample polishing machines optical machine uses Ø300mm aluminum grinding and polishing disc, which not only has excellent rigidity and internal compoundness, but also can obtain higher linear speed under the same rotation speed, thus improving the efficiency of sample production. The grinding and polishing speed of sample polishing machines is infinitely adjustable, and the pressure is manually controlled. It is simple to operate and easy to use. Sample polishing machines can be directly connected to tap water for cooling during the grinding process. Sandpaper or polishing pad can be installed by clamping ring or magnetic adsorption. It is easy to load and unload. Different installation methods can be selected according to personal needs.

Main features of sample polishing machines:

1. Polishing machine for metallographic samples can use the clamping ring or magnetic adsorption to place sandpaper or polishing pad, which makes the operation more stable.

2. The magnetic adsorption of polishing machine for metallographic samples is mainly to overcome the shortcomings of pleating of traditional clamping polishing fabric. The polishing fabric with pressure-sensitive adhesive is pasted on the polishing film, and then adsorbed on the magnetic sheet, which is more convenient for the replacement of sandpaper and polishing pad.

3. Polishing machine for metallographic samples has stepless speed regulation, digital display of revolutions, and easy operation. Beautiful appearance, stable operation, and low noise.

Technical parameters of heavy duty precision polishing machine:

Product Name | UNIPOL-1210 metallographic grinding and polishing machine / lapping machine |

Product Model | UNIPOL-1210 |

Installation Conditions | 1. Temperature and humidity: 10-85%RH (at 25℃ without condensation) Temperature: 0-45℃. 2. There is no strong vibration source and corrosive gas around the polishing machine for metallographic samples. 3. Power supply of the polishing machine for metallographic samples: Export standard equipment: AC110/230V 50/60Hz three-pole socket 10A. 4. Domestic standard equipment: AC220V 50Hz national standard three-pole socket 10A (the socket must have a good safety protection grounding wire). 5. Cooling water: The polishing machine for metallographic samples is equipped with an inlet and a drain, and you need to connect the tap water and drainage pipeline by yourself. 6. Air source: There is no requirement for standard equipment. 7. Workbench: It is recommended to use the polishing machine for metallographic samples on an operating table or desktop with a load of more than 100kg. 8. Ventilation device: In a good ventilation environment, the polishing machine for metallographic samples does not require special ventilation devices. 9. Auxiliary equipment (need to be purchased separately): Recommended: 1. SKCH-1 precision thickness gauge. 2. SZKD-2 automatic stirring dripper, SKZD-3 suspension dripper. 3. SKCS-1 blow dryer. |

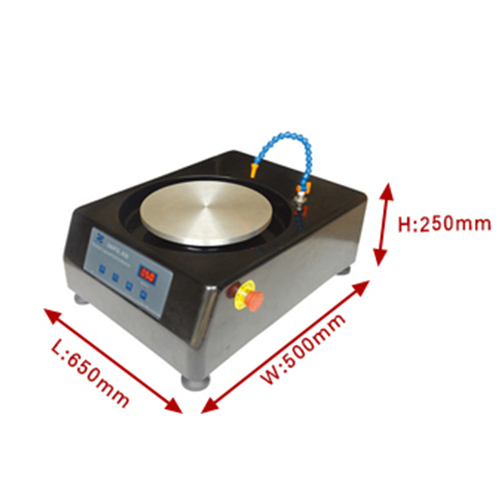

Main Parameters (Specification) | 1. Heavy duty precision polishing machine power supply port: AC110/220V conversion (domestic AC110V is invalid). 2. Total power: 180W. 3. Polishing disc diameter: Φ300 mm. 4. Polishing disc speed: 50-600rpm (adjustable). 5. Polishing disc station: 1 station. 6. Spindle drive motor: DC110V 165W. 7. Heavy duty precision polishing machine control mode: single chip microcomputer + button. Note: 1. Heavy duty precision polishing machine power supply is divided into export and domestic power supply. The actual power supply parameters are subject to the label attached to the back of the product. 2. Various polishing discs, special fixtures, special parts, etc. can be customized according to user requirements. |

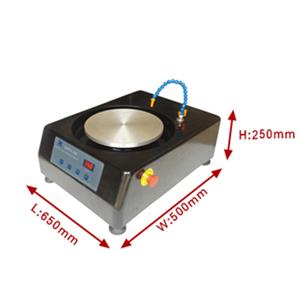

Product Dimension And Weight | 8. Product specifications: Dimensions: L650×W500×H250mm. Net weight: ≈33kg.

|

Standard accessories of sample polishing machines:

No. | Name | Qty | Picture |

1 | Magnetic Sheet | 4 pcs |  |

2 | Lapping Buffer Sheet | 5 pcs |  |

3 | Sandpaper | 2 pcs |  |

4 | Polishing Pad (Nubuck Leather, Synthetic Leather,) | 1 pcs each |  |

5 | Diamond Polishing Paste | 1 pcs |  |

Optional accessories of sample polishing machines:

No. | Name | Functional type | Picture |

1 | UNIPOL-01 Type TEM Wedge Grinding And Polishing Fixture | (optional) |  |

Warranty:

One year limited with lifetime support (not including rusted parts due to inadequate storage conditions).

Logistics:

About us:

Our laboratory has successfully prepared thousands of samples, covering a variety of materials and application areas. The preparation of each sample embodies the wisdom and hard work of the team. At the same time, the company also warmly welcomes customers from all over the world, and many foreign friends come from afar to visit and experience. By personally participating in the operation and testing of the laboratory, these customers deeply feel the excellent quality and technical advantages of our products. Every visit of a customer is a valuable opportunity for technical exchange and learning. The company also continuously improves and optimizes our products and services through interaction and feedback with customers to better meet the changing needs of the market.