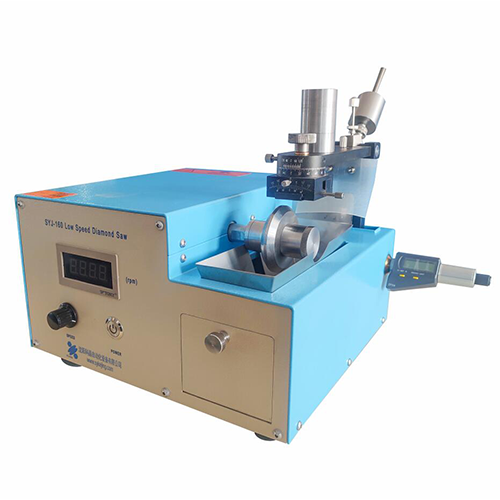

Low Speed Diamond Saw With 4" Cutting Blades

1. Diamond Saw is a cutting equipment suitable for precision cutting of material analysis samples. Diamond Saw can cut various crystals (sapphire, garnet, etc.), composite materials, organic polymer materials, etc.

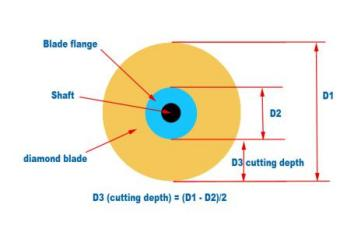

2.Diamond Saw can replace different Diamond Saw cutting blades according to different types of cutting materials.

3. Low speed diamond cutting machine is small in size and easy to operate. The spindle rotation speed of Diamond Saw is infinitely adjustable.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Diamond Saw main features:

1. Diamond Saw has high torque, low noise, smooth operation and compact structure.

2. The spindle of Diamond Saw has high operation precision, and the horizontal feed position of the sample processed by Low Speed Diamond Wheel Saw can be fine-tuned.

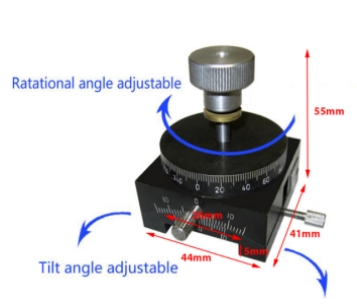

3.Diamond Saw is equipped with a 2D fixture so that the sample processed by Low Speed Diamond Saw can be positioned and cut at the best angle.

4. Low speed diamond cutting machine can be equipped with blades of various materials to meet the cutting requirements of different materials.

5. There is a coolant tank below the Low speed diamond cutting machine. As the Blade Saw rotates, the coolant is brought from the coolant tank to the sample, taking away the heat generated during the cutting process of the Blade Saw in time to prevent the sample from heating up and causing its texture to change.

6. The Low speed diamond cutting machine is equipped with a limit device to enable unattended cutting.

Low Speed Diamond Saw technical parameters:

Diamond Saw Standard Accessories:

No. | name | qty | picture |

1 | Adjustable 2D Fixture

| 1 set |  |

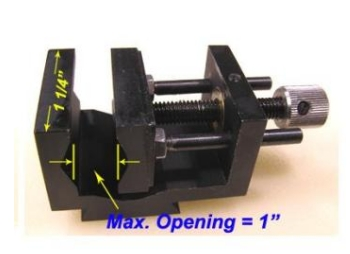

2 | Vise | 1 pcs |  |

3 | O-Ring of Driving Motor | 2 pcs | |

4 | Blade Clamp (Ø62mm、Ø48mm、Ø35mm) | total 3 sets | |

5 | Aluminum Plate (25mm×50mm×6mm) | 2 pcs |

|

6 | Resin Bonded Ceramics (50mm×50mm×10mm) | 2 pcs |

|

7 | Full-Sintered Diamond Blade (Ø100mm×Ø12.7mm×0.33mm) | 1 pcs |  |

8 | Electroplated Diamond Blade (Ø100mm×Ø12.7mm×0.5mm) | 2 pcs |  |

9 | Silicon Carbide Blade (Ø100mm×Ø12.7mm×0.4mm) | 10 pcs |

|

10 | Corundum Blade (Ø100mm×Ø12.7mm×0.4mm) | 10 pcs |

|

11 | Wax Bar | 4 pcs | |

12 | Goggles | 1 pair |

|

Low speed diamond cutting machine Optional Accessories:

No. | name | functional type | picture |

1 | Full Sintered Diamond Blade (Ø100mm×Ø12.7mm×0.33mm) | (optional) | |

2 | Electroplated Diamond Blade (Ø100mm×Ø12.7mm×0.4mm) | (optional) |  |

3 | Silicon Carbide Blade (Ø100mm×Ø12.7mm×0.4mm) | (optional) |  |

4 | Corundum Blade (Ø100mm×Ø12.7mm×0.4mm) | (optional) |  |

5 | Edge Sintered Diamond (Ø100mm×Ø12.7mm×0.33mm) | (optional) | |

Low Speed Diamond Saw Remarks and Warnings/Cautions:

1. During the cutting process of Low Speed Diamond Wheel Saw, you need to use cutting fluid containing cooling powder, or anti-corrosion fluid such as rust inhibitor and emulsion. Low Speed Diamond Wheel Saw Avoid direct water cooling to prevent the saw from rusting.

2. When stopping the Low Speed Diamond Wheel Saw, the Low Speed Diamond Saw speed should be reduced to zero (stop), and then the power switch can be turned off before the sample can be taken out.

3. When starting the Blade Saw, please ensure that the sample is fixed and clamped firmly, turn the speed knob counterclockwise to zero, then turn on the switch, and then increase the Blade Saw speed.

4. After each use of the Low Speed Diamond Wheel Saw, the clamp andLow Speed Diamond Saw should be cleaned and protected, dried, oiled, and rust-proofed before storing the Low Speed Diamond Wheel Saw.

5. To prevent oxidation or contamination of the sample cutting surface, the Low Speed Diamond Wheel Saw can be operated in a nitrogen-filled glove box, but the Low Speed Diamond Saw cannot be operated in an argon-filled glove box (that is, there is nitrogen in the glove box, but no argon) ).

Diamond Saw warranty:

One year limited with lifetime support (not including rusted parts due to inadequate storage conditions).

Enterprise strength:

Shenyang Kejing Automation Equipment Co., Ltd. was founded in May 2000. Since the birth of the first SYJ-150 low-speed diamond cutting machine, Shenyang Kejing has begun a development process with the goal of catching up with its foreign counterparts and leading the trend of material analysis equipment. Today, it has hundreds of products covering material cutting, grinding, polishing, coating, coating, mixing, rolling, sintering, analysis and other fields as well as related consumables, which can meet the needs of crystals, ceramics, glass, petrography, minerals, etc. A complete set of needs for the preparation and analysis of samples, metal materials, refractory materials, and composite materials.