- Home

- >

News

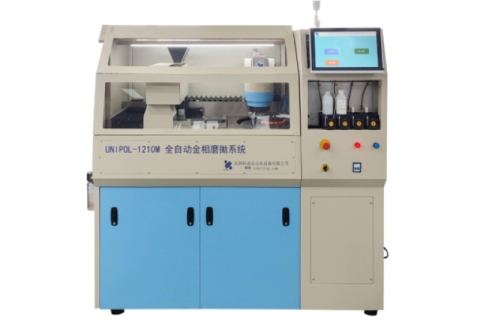

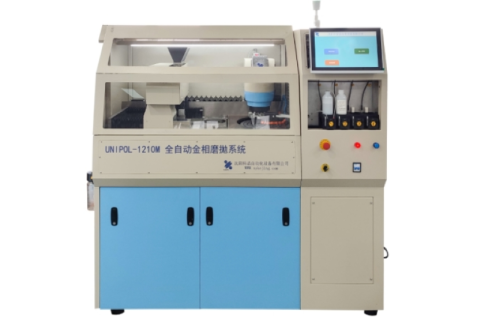

In materials science research, the efficiency and accuracy of the metallographic sample preparation process directly affect the reliability of experimental results. In order to meet the needs of scientific research institutions and industrial laboratories for automation, precision and consistency, we have developed a device called "UNIPOL-1210M fully automatic metallographic grinding and polishing system", which not only provides a highly integrated sample preparation solution, but also can cover a series of full-process automated operations such as mounting, grinding, polishing and cleaning. Let's take a look at how the automatic grinding and polishing machine performs at work!

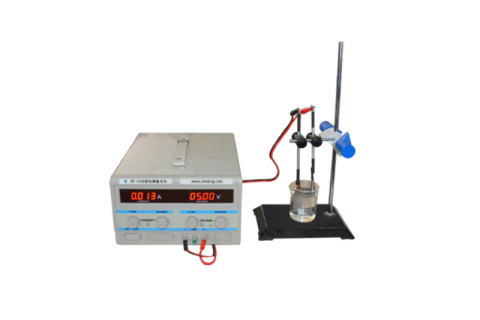

In the field of metallographic analysis, the sample preparation process is crucial to the accuracy of the experimental results. The EP-6100 electrolytic polishing corrosion instrument, with its excellent performance and efficient operation, has become an ideal choice for preparing metallographic samples. The electrolytic polishing corrosion instrument combines polishing and corrosion functions through the electrochemical principle, which not only achieves efficient sample preparation, but also does not produce deformation layers caused by mechanical processing. The reliability of the experimental results has been greatly improved.

The EP-1060 electrolytic polisher has become an indispensable tool in metallographic specimen preparation due to its excellent functionality and portability. However, in order to better utilize the equipment performance, while ensuring the safety of laboratory personnel and the long-term use of the equipment, it is particularly important to operate and maintain the equipment correctly. The following are key considerations for the operation and maintenance of electrolytic polishers and etchers for metallography. Let's take a look!

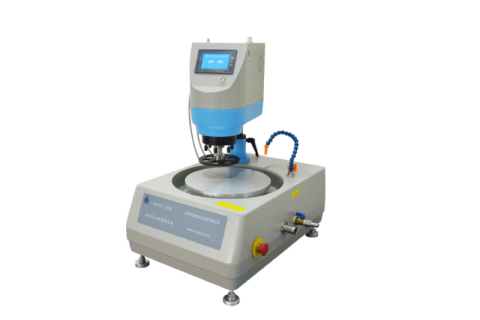

In modern industry and scientific research, the demand for precision processing of materials is becoming more and more stringent. Whether in the steel manufacturing industry or in the high-tech field, the surface quality and grinding accuracy requirements for artificial crystals, ceramics and infrared optical materials (such as zinc selenide, zinc sulfide, silicon and germanium, etc.) have reached new heights. UNIPOL-1260A Vacuum and heating grinding and polishing machine is designed for such high-precision processing needs. It is widely used in the grinding and polishing of hard and brittle materials such as quartz glass, rock, white gemstone and sapphire, meeting the diverse application needs from laboratories to large-scale production workshops.

UNIPOL-1260 Stepless variable speed pressure regulating polishing machine has become the preferred equipment for steel plants and metallographic sample preparation due to its precise and efficient grinding capabilities. Whether it is artificial crystals, ceramics or infrared optical materials, stepless variable speed pressure regulating polishing machine can achieve high-precision processing, shortening sample preparation time while improving sample preparation quality. Next, please appreciate its performance with me!

In modern manufacturing, UNIPOL-1200M automatic pressure grinding and polishing machine is a key equipment and is widely used in many industries such as metal, ceramics, glass and composite materials. The unique surface treatment ability of desktop grinding and polishing machine not only improves the appearance quality of the product, but also significantly improves the mechanical properties and processing accuracy of the material. Let's take a look at how desktop grinding and polishing machine is used in different fields!

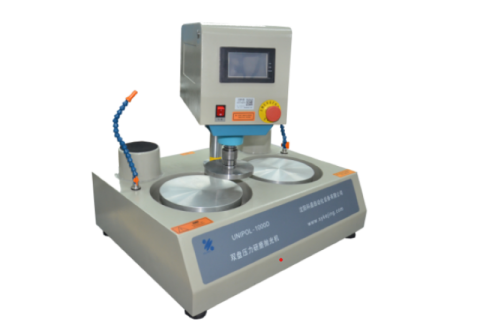

In the field of materials research, UNIPOL-1000D double disc pressure grinding and polishing machine has become an indispensable equipment in laboratories of major universities, research institutes and small-scale production in factories with its high efficiency and wide applicability. With its double-station design, the double disc grinding and polishing machine not only effectively avoids cross contamination between grinding and polishing, but also significantly improves work efficiency.

In the production and processing process, the normal operation of the UNIPOL-800m multi-point mechanical pressure grinding and polishing machine is crucial to ensure the quality of the workpiece. However, in daily use, various problems may occur, affecting the processing effect of the workpiece. This article summarizes several common faults of automatic pressure grinding and polishing machine and the corresponding solutions to help manufacturers maintain equipment in a timely manner and improve production efficiency.

With the rapid development of the semiconductor industry, the size of electronic devices continues to shrink, and the requirements for wafer surface flatness are becoming more stringent. Especially in today's integrated circuit manufacturing process, the wafer surface needs to be flattened at the nanometer level, and traditional local flattening technology can no longer meet this demand. However, our UMIPOL-1203 chemical mechanical polishing machine can currently achieve global flattening.

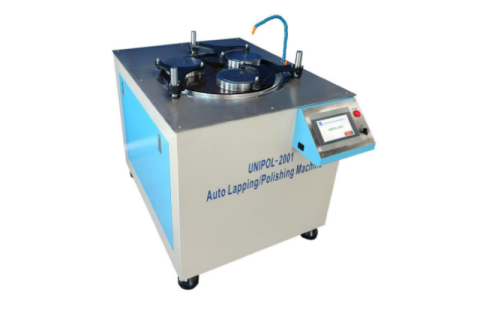

UNIPOL-2001 precision grinding and polishing machine has become a hot spot in the field of scientific research and material processing due to its versatility and excellent performance. The laboratory grinding polishing machine has an advanced design and is specially designed for high-precision grinding and polishing of various materials such as crystals, ceramics, metals, glass, rock samples, and mineral samples, providing users with an efficient and convenient processing method.

How to choose the most suitable precision automatic lapping machine? This is a crucial question for enterprises and scientific research institutions of different sizes. There are many types of precision automatic lapping machines on the market, and each has its own unique functions. Choosing a suitable precision automatic lapping machine requires comprehensive consideration of actual needs, material properties, production process requirements and other aspects. The following points can help you make a wise choice.