Efficient And Intelligent Material Processing Tool

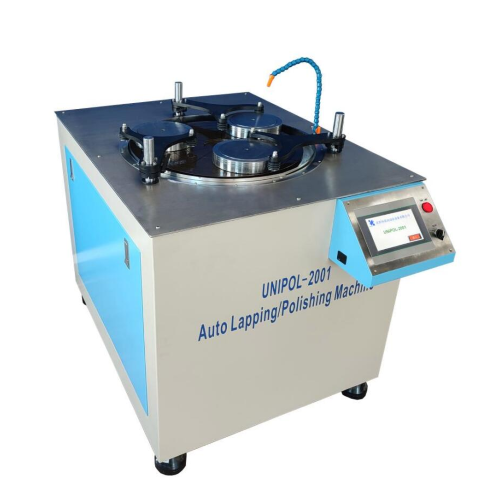

2024-10-21 15:30UNIPOL-2001 precision grinding and polishing machine has become a hot spot in the field of scientific research and material processing due to its versatility and excellent performance. The laboratory grinding polishing machine has an advanced design and is specially designed for high-precision grinding and polishing of various materials such as crystals, ceramics, metals, glass, rock samples, and mineral samples, providing users with an efficient and convenient processing method.

The laboratory grinding polishing machine is equipped with a large grinding and polishing disc with a diameter of 508mm and three independent processing stations. The laboratory grinding polishing machine can easily process material samples with a diameter or diagonal of no more than 160mm. The unique left-right swing design of the laboratory polishing machine for metal ensures that the sample surface is uniform and smooth, which is particularly suitable for precision sample processing with high requirements on the edge. In addition, the high-precision load block equipped with the laboratory polishing machine for metal makes the surface of the ground sample have extremely high flatness and parallelism, making the processing quality even better.

The laboratory polishing machine for metal also has a high-precision rotary chuck, supports stepless speed regulation and timed polishing, and meets a variety of needs from single samples to mass production. For mass production needs, users can choose the GPC series precision grinding and polishing controller to quickly and efficiently process high-quality flat products, such as wafer samples.

According to the characteristics of different materials, laboratory precision polishing machine allows users to flexibly choose sandpaper or abrasives for processing. The magnetic adsorption device makes the replacement of sandpaper or polishing pads more convenient, effectively saving operating time. In addition, users can also choose to equip the laboratory precision polishing machine is automatic feeder to further improve processing efficiency. It is worth mentioning that the laboratory precision polishing machine provides a series of optional accessories to meet the personalized processing needs of different materials. Users can choose grinding discs made of cast iron, cast aluminum or glass to customize the configuration according to the specific needs of the sample.

With its leading design concepts and rich product lines, Shenyang Kejing not only provides customers with high-quality products, but also significantly improves user experience and processing efficiency through flexible customized accessories and intelligent operations. In the future, the company will continue to uphold the spirit of technological innovation and provide customers around the world with more excellent material preparation machines.