Why Is The Electrolytic Polishing Corrosion Instrument So Reliable?

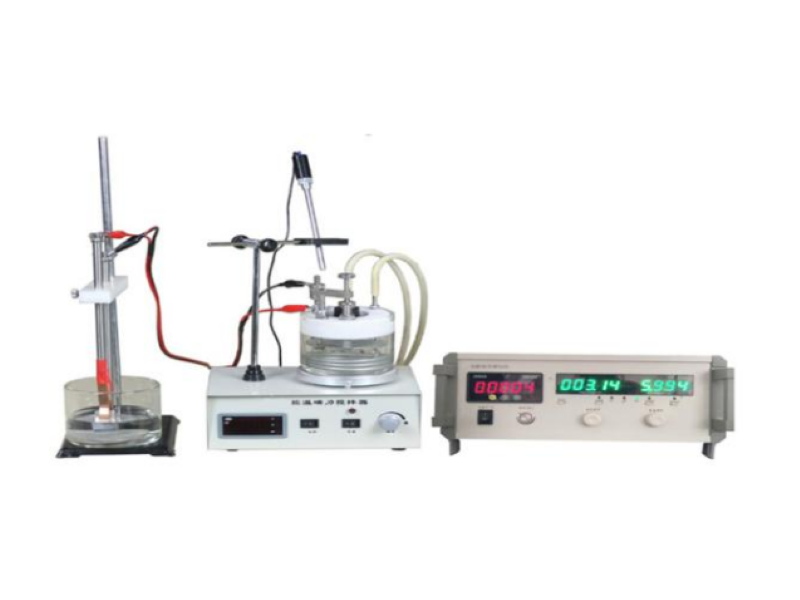

2024-12-06 15:30In the field of metallographic analysis, the sample preparation process is crucial to the accuracy of the experimental results. The EP-6100 electrolytic polishing corrosion instrument, with its excellent performance and efficient operation, has become an ideal choice for preparing metallographic samples. The electrolytic polishing corrosion instrument combines polishing and corrosion functions through the electrochemical principle, which not only achieves efficient sample preparation, but also does not produce deformation layers caused by mechanical processing. The reliability of the experimental results has been greatly improved.

Core advantages:

1. Wide range adaptability: The electrolytic polishing corrosion instrument has a wide range of voltage and current adjustment capabilities, which can flexibly adapt to the polishing and corrosion requirements of different materials.

2. Accurate constant control: The electrolytic polishing corrosion instrument supports two working modes: Constant current and constant voltage, and ensures the stability of the polishing or corrosion current through intelligent control technology, providing users with consistent and repeatable experimental results.

3. Multi-dimensional parameter adjustment: By accurately controlling the polishing/corrosion area, medium temperature and experimental time of the sample, the experimental process is further optimized, making each step controllable and adjustable.

4. Efficient uniformity: The built-in stirring device evenly distributes the polishing/corrosion medium, and the heating device allows users to set the ideal polishing/corrosion temperature.

5. Customized function options: In order to meet more refined experimental needs, the electrolytic corrosion polishing machine supports customized adjustment of voltage and current, and provides coarse and fine adjustment switching functions, which facilitates parameter setting both quickly and accurately, helping users to obtain a more efficient experimental experience.

Wide range of applications:

The electrolytic corrosion polishing machine not only has a fast sample preparation speed, but also has good repeatability. It is an excellent assistant in industrial laboratories, scientific research institutions and education and training fields. Whether it is used for polishing non-ferrous metals or corroding stainless steel samples, it can solve experimental problems for users with its excellent performance.

The electrolytic corrosion polishing machine is not only an improvement in experimental efficiency, but also a comprehensive guarantee for experimental accuracy and reliability. Equipping the laboratory with such a device can not only improve work efficiency, but also set a benchmark for high-quality scientific research. If you are looking for an electrolytic polishing and corrosion instrument with both high performance and high adaptability, it will be a good choice!