How To Use Electrolytic Polishing Corrosion Tester Efficiently?

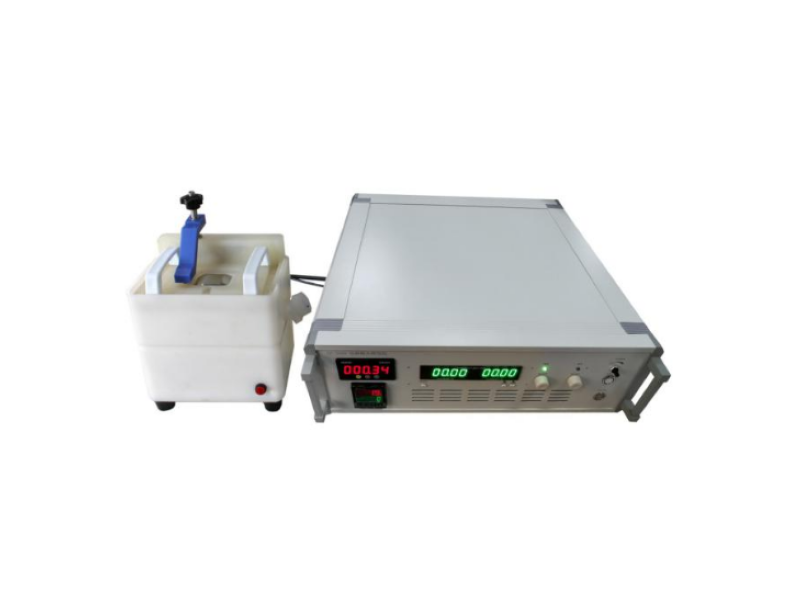

2024-12-04 15:30The voltage-stabilized power supply of the EP-2060 electrolytic polishing corrosion tester is based on soft switching technology, which reduces switching losses and achieves more efficient energy conversion. Its output voltage can be set arbitrarily from zero to the nominal value, and the current limiting protection point can also be flexibly adjusted to support a variety of experimental needs. In addition, both the voltage-stabilized mode and the current-stabilized mode can be continuously adjusted, further improving the applicability and operating accuracy of the electrolytic polishing corrosion tester. So let's take a look at how it operates at work!

1. Instructions for use:

In order to facilitate user operation, the power supply is designed with a clear and easy-to-understand usage process:

Connection and start: After plugging in the power supply and connecting the output load, turn on the side power switch.

Preset parameters: Adjust the voltage and current through the display buttons. In the constant voltage mode, adjust the current to the maximum, and in the constant current mode, adjust the voltage to the maximum.

Set the experimental time: Enter the time adjustment function through the "SET" button, and use the adjustment button to complete the parameter setting.

Start the experiment: After the parameter setting is completed, press the system start button, and the electrolytic polishing corrosion tester can work normally.

This concise operation process not only improves the experimental efficiency, but also reduces the risk of operating errors, providing users with a more reliable use experience.

2. Notes:

Preset before startup: Be sure to complete parameter preset before starting the electrolytic polishing corrosion tester to avoid accidents during the experiment.

Light load adjustment: Under light load or no-load conditions, adjust the output voltage slowly to prevent voltage fluctuations from getting out of control.

Power off during maintenance: When repairing the electrolytic polishing and etching instrument, the input voltage must be disconnected first to ensure safe operation.

Reliable grounding: The protective grounding terminal of the input power cord must be grounded to ensure that the electrolytic polishing and etching instrument will not cause safety hazards due to leakage during use.

The electrolytic polishing corrosion tester provides strong support for laboratory research, industrial production, education and training with its high efficiency, flexibility and reliability. It can not only improve experimental efficiency, but also greatly reduce operational difficulty and safety risks. In the future, with the further optimization of equipment performance, the equipment will play a role in a wider range of application scenarios, allowing technology to better serve social progress.