- Home

- >

News

With the continuous development of modern materials science and industrial manufacturing, the requirements for the preparation accuracy and efficiency of metallographic samples are getting higher and higher. Our UNIPOL-1210 metallographic grinding and polishing machine provides efficient and precise metallographic sample preparation solutions for scientific research institutions and enterprises. In order to ensure the good performance of the equipment during use and extend its service life, it is particularly important to understand the operating specifications and daily maintenance of the equipment. Let's learn about it together!

With the increasing demand for precision grinding and polishing technology in scientific research and industrial production, Shenyang Kejing launched the UNIPOL-1202 precision auto polishing machine. This equipment provides efficient, precise, flexible and customizable solutions for various materials. Precision auto polishing machine is an ideal choice for scientific research institutions, laboratories and production enterprises. It is especially suitable for high-quality surface treatment requirements, such as crystals, ceramics, metals, glass, rocks, minerals, PCB boards and infrared optical materials.

Metallographic manual polishers are widely used in the field of material science research. They are mainly used to grind and polish the surface of metals, non-metals and other materials to obtain a smooth and flat surface. When operating the single position grinding polishing machine, mastering some grinding and polishing skills can improve work efficiency and surface quality. In this article, we will introduce the grinding and polishing skills of the single position grinding polishing machine to help you better use and maintain the equipment.

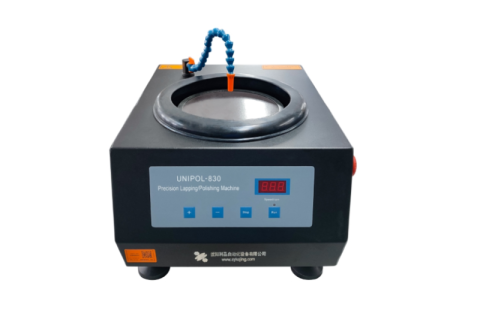

During the use of UNIPOL-810 precision auto lapping and polishing machine, if sparks appear inside the grinding and polishing machine, this may be caused by a variety of factors. In order to ensure the safe operation of the grinding and polishing machine and excellent processing results, please pay attention to potential problems of the product in a timely manner and take corresponding preventive measures. Correct operation and regular maintenance are important links to ensure the performance of the equipment. Stay highly alert to ensure the safety and smoothness of the processing process. So let's take a look at what causes sparks inside the grinding and polishing machine!

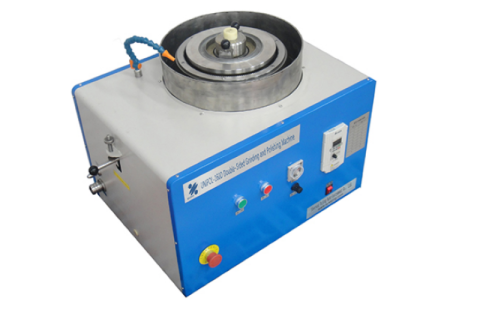

In materials science research, metallographic preparation is a crucial link, and the grinding and polishing step is the key to ensuring high-quality metallographic samples. However, researchers often encounter a series of problems when performing metallographic grinding and polishing, such as grinding and polishing marks, sample cracks, uneven polishing fluid, etc. Shenyang Kejing's UNIPOL-820 dual platens lapping and polishing machine is specially designed to solve these problems and can help researchers complete metallographic preparation more efficiently and obtain clear and accurate metallographic observation results.

The UNIPOL-300 small precision grinding and polishing machine launched by Shenyang Kejing has quickly become an ideal choice for metallographic laboratories and electron microscopy laboratories with its excellent precision and intelligent operation. Next, please come with me to see the excellent performance of small precision grinding and polishing machine in production!

With the long-term use of UNIPOL-160D double-sided lapping and polishing machine, some common faults may affect production efficiency and processing quality. Therefore, understanding the causes and solutions of these faults can help you effectively extend the service life of dual face lapping and polishing machines and ensure the stability of production.

The third "Kejing Cup" Basketball Match