Do You Know How To Solve Common Double Sided Lapping Machine Problems?

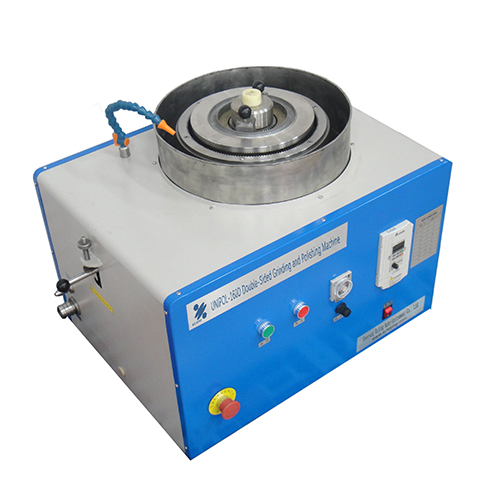

2024-09-25 15:30With the long-term use of UNIPOL-160D double-sided lapping and polishing machine, some common faults may affect production efficiency and processing quality. Therefore, understanding the causes and solutions of these faults can help you effectively extend the service life of dual face lapping and polishing machines and ensure the stability of production.

Common faults:

1. Decreased grinding accuracy.

Reason:

Grinding wheel wear: After long-term use, the surface of the grinding wheel will gradually wear, resulting in reduced grinding accuracy of dual face lapping and polishing machines.

Workpiece is not firmly fixed: If the workpiece is not firmly fixed during the grinding process, it will shake, thus affecting the grinding accuracy.

Improper equipment adjustment: For example, unreasonable settings of parameters such as the rotation speed and feed speed of the grinding wheel will also lead to reduced accuracy of dual face lapping and polishing machines.

Performance: The surface roughness of the workpiece after processing increases, and the dimensional deviation exceeds the allowable range.

2. Abnormal equipment vibration.

Reason:

Grinding wheel imbalance: The grinding wheel may be unbalanced during installation or use, resulting in vibration of dual face lapping and polishing machines.

Failure of transmission components: Such as loose belts and worn gears, which will cause unstable operation of the double-sided precise lapping machine and generate vibration.

Unsound foundation: If the foundation on which the double-sided precise lapping machine is installed is not solid, it will also generate vibration during operation.

Performance: The double-sided precise lapping machine generates obvious vibration and noise during operation, which may affect the normal operation of the equipment in severe cases.

Double-end grinding machine

3. Electrical failure.

Cause:

Short circuit or open circuit. It may be caused by aging, breakage of wires, or damage to electrical components.

Motor failure. Problems such as overheating and burning of the motor will cause the double-sided precise lapping machine to fail to operate normally.

Control system failure. Such as control panel failure, program error, etc.

Performance: The double sided lapping machine cannot be started or stopped, or abnormal movements occur during operation.

Solution:

1. For the decrease in grinding accuracy:

Check and replace the grinding wheel regularly to ensure that the surface condition of the grinding wheel is good.

Strengthen the fixation of the workpiece, use appropriate fixtures and fixing methods to ensure that the workpiece does not shake during the grinding process.

According to the material and processing requirements of the workpiece, reasonably adjust the parameters of the double sided lapping machine, such as grinding wheel speed, feed speed, etc.

2. For abnormal vibration of the double sided lapping machine:

To balance the grinding wheel, you can use a professional balanced double sided lapping machine for adjustment.

Check the transmission parts and replace worn belts and gears in time to ensure the normal operation of the transmission system.

Strengthen the foundation where the equipment is installed to ensure that it is firm and stable.

3. Deal with electrical faults:

Check the circuit, find out the short circuit or open circuit and repair it. Replace aging and broken wires, and repair or replace damaged electrical components.

If the motor fails, it should be repaired or replaced in time.

Check the control system, repair or replace the failed control panel, and eliminate program errors.

In order to help enterprises better deal with these double sided lapping machine failure problems, our company focuses on providing high-quality double-sided grinding and polishing machines and their accessories. Our equipment adopts the latest technology and precision design, and still maintains excellent grinding accuracy after long-term operation. At the same time, we also provide perfect after-sales service to promptly solve various problems encountered by customers during use. By choosing our company's products, you can not only improve production efficiency, but also reduce unnecessary costs caused by equipment maintenance.