Operation Guide And Maintenance Of Metallographic Sample Grinding And Polishing Machine

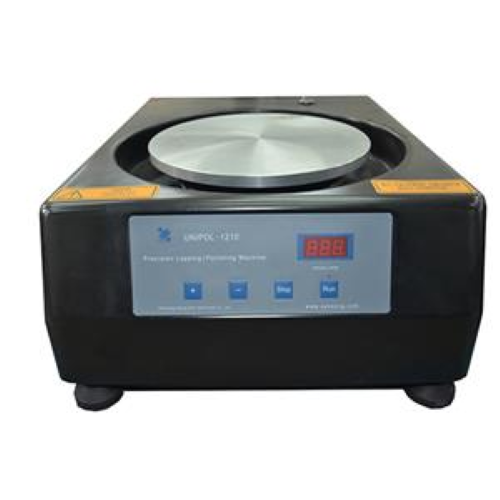

2024-10-12 15:30With the continuous development of modern materials science and industrial manufacturing, the requirements for the preparation accuracy and efficiency of metallographic samples are getting higher and higher. Our UNIPOL-1210 metallographic grinding and polishing machine provides efficient and precise metallographic sample preparation solutions for scientific research institutions and enterprises. In order to ensure the good performance of the equipment during use and extend its service life, it is particularly important to understand the operating specifications and daily maintenance of the equipment. Let's learn about it together!

Precautions for the operation of the heavy duty precision polishing machine:

1. Disk loading and setting:

Before using the heavy duty precision polishing machine, you need to remove the water retaining ring and replace the required grinding disc or polishing disc. When installing the magnetic plate and sandpaper, make sure the surface is clean to avoid affecting the grinding and polishing effect. After the heavy duty precision polishing machine sets the speed, pressure and other parameters through the touch screen, it can start grinding and polishing.

2. Pre-grinding operation:

The sandpaper with adhesive backing is pasted on the pad, and the pad is adsorbed on the magnetic disk through permanent magnets. The sandpaper needs to be kept moist during pre-grinding, but the amount of water should not be too large, and continuous flow is sufficient.

3. Polishing operation:

The installation of the polishing cloth is similar to pre-grinding, ensuring that the cloth fits flatly on the disk surface. Then drip polishing liquid or polishing paste on the cloth as needed, and adjust the appropriate amount of water for polishing operation. Pay attention to the fixing method of different fabrics to ensure the safety of operation and polishing effect.

4. Shutdown operation:

After using the sample polishing machines, the water supply valve should be closed before shutting down to prevent water from entering the bearing seat and affecting the service life of the equipment.

5. Cleaning and maintenance:

Regular cleaning can maintain the optimal performance of the sample polishing machines. Cleaning includes cleaning the polishing disc, sample mold sleeve, drainage pipeline and the outside of the equipment. Avoid using corrosive cleaning agents during use to avoid damaging the equipment.

Care and maintenance of polishing machine for metallographic samples:

1. Do not apply excessive pressure to the sample during polishing to avoid damage to the motor due to overload.

2. It is forbidden to grind and polish damaged fabrics to avoid affecting the polishing quality and causing accidents.

3. Polishing machine for metallographic samples should be cleaned and maintained in time every day after use, and the sedimented dirt in the dirt collection tray and drainage pipe should be removed to facilitate smooth drainage. When not in use, the plastic cover should be covered in time to avoid debris leaks into the plate, affecting the quality of subsequent grinding and polishing.

4. After long-term use of polishing machine for metallographic samples, the grease in the motor bearings should be replaced in time.

5. The configured air filter is a mechanical automatic drainage filter valve. Please place it correctly according to the instructions and clean the filter element regularly to avoid component damage.

Shenyang Kejing has always been committed to providing customers with efficient, stable equipment and all-round technical support. From equipment installation and debugging to after-sales service, company provides complete solutions. Through daily operation and maintenance, the metallographic sample grinding and polishing machine can maintain its best condition for a long time, providing reliable guarantee for scientific research and production.