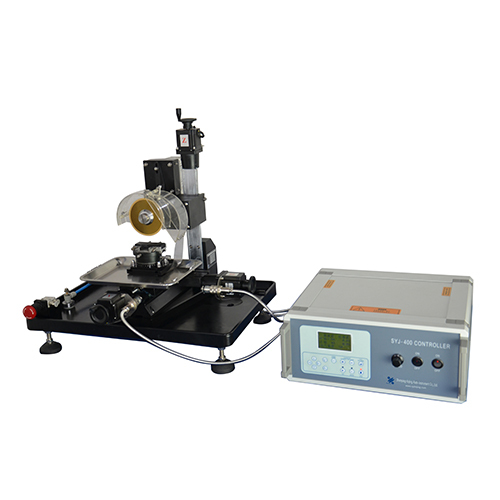

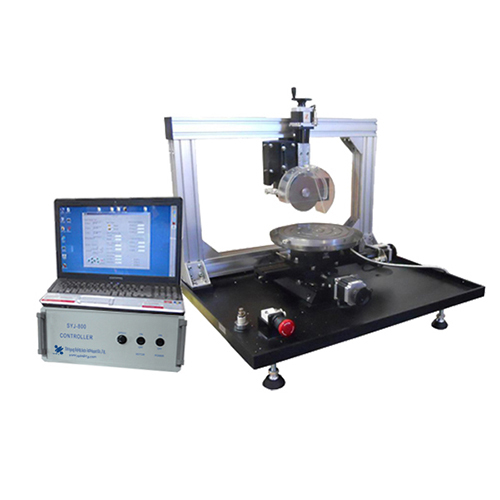

Precision Dicing Saw with 8 inches round and 205mm square workbench

1.SYJ-1802precision wafer dicing saw adopts imported air static pressure spindle, which has the characteristics of high precision, good rigidity, high output power, low noise and long life.

2.The spindle speed of Precision wafer dicing saw is set independently, and the running status is monitored in real time.

3.The X, Y and Z axes of Precision wafer dicing saw adopt imported linear guide rails and ball screws, and the Y axis grating is fully closed-loop controlled, mathematical model fitting, and the precision is higher. The workbench is 8-inch round and 205mm square.

- Shenyang Kejing

- Shenyang, China

- 22 working days

- 50 sets

- Information

Main features of precision silicon wafer cutting saw

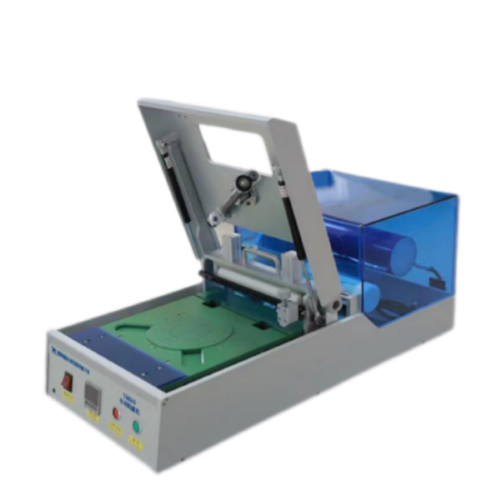

1. Precision silicon wafer cutting saw is small in size and saves space

2. Precision silicon wafer cutting saw is easy to operate, touch-operated, and has a 15-inch high-precision touch screen.

3. Silicon wafer cutting saw can be intelligently and accurately aligned automatically to reduce manual operation.

4. Silicon wafer cutting saw adopts variable speed blade height measurement design, which is safe and reliable, effectively protects the blade, and is equipped with non-contact. Touch height measurement function to achieve height measurement operation during the marking process.

5. The core components such as the spindle are imported as standard and can be adjusted according to needs.

6. Spindle working status detection, automatic locking of the studio door, and safety information prompts.

7. Silicon wafer cutting saw can be customized with special cutting process design.

8. Silicon wafer cutting saw has high cutting accuracy and good equipment stability.

9. Direct drive rotation angle.

Technical parameters of precision wafer dicing saw

Product name | SYJ-1802 precision dicing saw |

Product model | SYJ-1802 |

Major parameters (specifications) | 1. Power supply: 220VAC±10%, single-phase. 2. Power: 3.0kW. 3. Spindle speed: 3000~50000rpm. 4. Spindle output power: 1.5KW. 5. X-axis cutting distance: Max 345mm. 6. X-axis speed range: 0.1~400mm/s. 7. Y-axis cutting distance: Max 210mm. 8. Y-axis single-step stepping accuracy: 0.003mm/5mm. 9. Max tolerance of the whole Y axis: 0.005mm/210mm. 10. Z-axis effective cutting distance: Max 30mm 11. Z-axis repeatable positioning accuracy: 0.001mm. 12. Z-axis blade application size: φ50mm~φ60mm. 13. θ-axis drive mode: DD motor. 14. θ-axis rotation angle range: 320°. 15. θ-axis resolution: 1″. 16. Lighting source: LED ring light source + coaxial light. 17. CCD: industrial camera.. 18. Display: Industrial grade 15" color LCD touch screen. 19. Control system: PC Base+WindowsXP. 20. Operating system: Windows© XP. 21. Language: Chinese. |

Product specifications | 1. Working size: Φ2″- Φ8″. 2. Round workbench: Φ8″. 3. Square workbench: 205mm × 205mm. 4. Volume (W× D× H) mm: 960×820×1700. 5. Net weight: 550Kg. |

Warranty

One year limited with lifetime support (not including rusted parts due to inadequate storage conditions)

Logistics

About us:

We not only pursue excellence in product quality, but also pay attention to details in logistics and packaging. We are well aware that the transportation process of precision instruments is extremely important. Once damaged, it will affect the normal production of customers. Packaging is a key link to ensure product safety. Our packaging team has undergone rigorous training and mastered the packaging skills of precision instruments. To this end, we have established a complete logistics system and cooperated with world-renowned logistics companies to ensure that every dicing machine can be delivered to customers safely and on time.