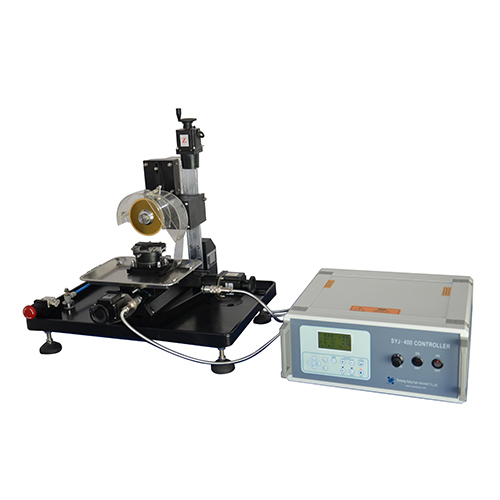

Precision CNC Cutting And Dicing Saw

1. Our Laboratory cutting machine has a fast cutting speed and can meet your different needs.

2. Our Laboratory cutting machine is designed and produced by our company with a one-year warranty.

3. Our company has quality assurance for Laboratory cutting machine. If you have any questions, you can contact us at any time.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Introduction of laboratory cutting machine:

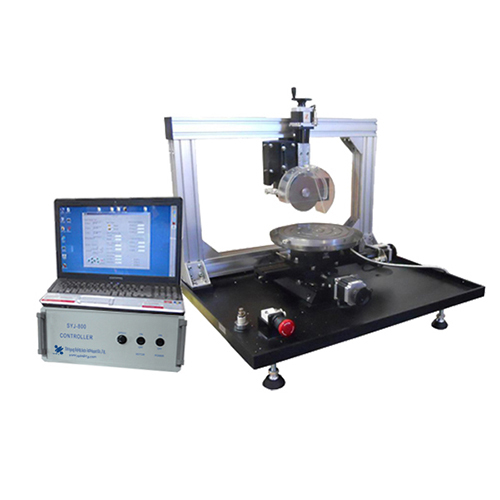

SYJ-400 CNC laboratory precision micro cutting machine is mainly suitable for dicing, grooving and cutting of various materials such as crystals, ceramics, glass, ore, metal, etc. Laboratory precision micro cutting machineadopts a stepper motor, and can be computerized with a position accuracy of 0.01 mm. Laboratory precision micro cutting machine can be rotated at 360°, Laboratory cutting machinewith a cross mount vise (with 90° positioning die to ensure the accuracy of cutting) and a vacuum chuck(Optional).

Main features of metal cutting circular saw:

Computerized control, allowing users to program sample cutting by themselves

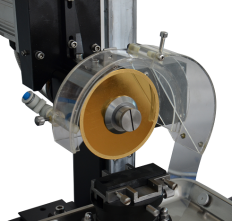

Adopting large-torque AC brushless motor to drive the spindle through belt pulleys and adjusting rotating speed 0-3000rpm through speed regulating buttons

Choosing proper blade and blade clamp according to the size of material samples

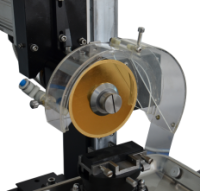

Equipped with a splash-protection cover and a throttle valve to control coolant flow

Technical parameters of metal cutting circular saw

Product Name | SYJ-400 CNC Dicing / Cutting Saw | |

Model of metal cutting circular saw | SYJ-400 | |

Installation conditions of metal cutting circular saw | 1. Temperature and humidity: 10-85%RH (at 25℃ without condensation) Temperature: 0-45℃. 2. There is no strong vibration source and corrosive gas around CNC cutting and dicing saw. 3. Power supply: AC110V 60Hz American standard three-pole socket (customized machine). AC220V 50Hz National standard three-pole socket. 4. Cooling water: CNC cutting and dicing saw is equipped with water inlet and outlet, and you need to connect tap water and drainage devices by yourself. 5. Air source: no requirement for standard equipment. 6. Workbench: size 800mm×600mm×700mm, load-bearing more than 50kg. 7. Ventilation device: good ventilation environment, no special ventilation device requirements. | |

Major Parameters (Specifications) of metal cutting circular saw | 1. Power supply port: AC220V 50Hz. 2. Spindle speed: 0-3000rpm stepless speed regulation. 3. Spindle drive power: 180W. 4. X-axis slide travel: 210mm. 5. Y-axis slide travel: 110mm. 6. Z-axis slide travel: 90mm. 7. Cutting depth max: 50mm. 8. X/Y/Z-axis drive motor: high-precision stepper motor. 9. Stepper motor positioning accuracy: 0.01mm. 10. Workbench angle and error: 360°±0.5°. 11. Loading block size of wafer dicing machine: 80mm×25.4mm. 12. Saw blade size: Ø100/Ø150mm×Ø12.7mm (inner diameter installation size). 13. Host control mode: Single-board model: control panel + single-board computer. Computer version: computer program (USB) + single-board computer. | |

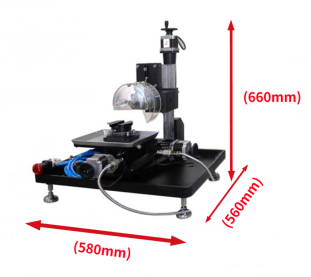

14. Specifications of CNC cutting and dicing saw: ·Size: 580mm×560mm×660mm ·Weight: ≈39kg |

| |

Notes of wafer dicing machine: 1. The domestic standard power supply of CNC cutting and dicing saw is AC220V 50Hz. The actual power supply parameters are subject to the label attached to the back of the product. 2. CNC cutting snd dicing saw supports customized AC110V 60Hz power supply equipment. 3. If you customize the computer version of CNC cutting and dicing saw, you need to bring your own computer as the device control host to use this device. CNC cutting and dicing saw comes with a "U disk installation program". | ||

Standard accessories of metal cutting circular saw:

No. | name | qty | picture |

1 | Saw pads | total 3 sets |

|

2 | Cross clamp | 1 set | |

3 | Aluminum load block | 2 pcs |

|

4 | Resin Bonded Ceramics (50×50×10mm) | 2 pcs | |

5 | Fully Sintered Diamond Blade (Ø100mm×Ø12.7mm×0.33mm) | 1 pcs |

|

6 | Electroplated Diamond Blade Ø100mm×Ø12.7mm×0.5mm | 2 pcs |

|

7 | Paraffin wax stick | 4 pcs |

|

8 | Waterproof cover | 1 set | |

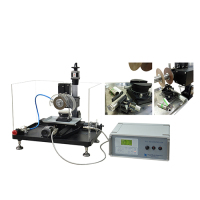

9 | Goggles | 1 pair |

|

Optional Accessories:

No. | name | functional type | picture |

1 | Edge Sintered Diamond Blade (Ø100mm×Ø12.7mm×0.33mm) | (optional) |

|

2 | Sintered Diamond Dicing Blade | (optional) | |

3 | Oilless Vacuum Pump | (optional) | |

4 | JXZ-25Y Coolant Circulating Tank (with Pump) | (optional) | |

5 | Heating Plate | (optional) |  |

Remarks and Warnings:

· wafer dicing machineis recommended that customers use anti-corrosion coolant during the cutting process to avoid rusting of the lead screw.

· Be sure to clean the machine after each use, especially clean the lead screw with lubricant to make sure that X, Y and Z axles can move freely without blocking or rusting.

Warranty of wafer dicing machine:

One year limited with lifetime support (not including rusted parts due to inadequate storage conditions)

Logistics of wafer dicing machine:

About us:

To ensure that every wafer dicing machine received by customers is intact, we strive for excellence in logistics and packaging. We use international standard packaging materials and methods, combined with professional loading technology, to minimize the risks in transportation. At the same time, we cooperate with many international logistics companies to ensure that the wafer dicing machine can be delivered to customers safely and on time.