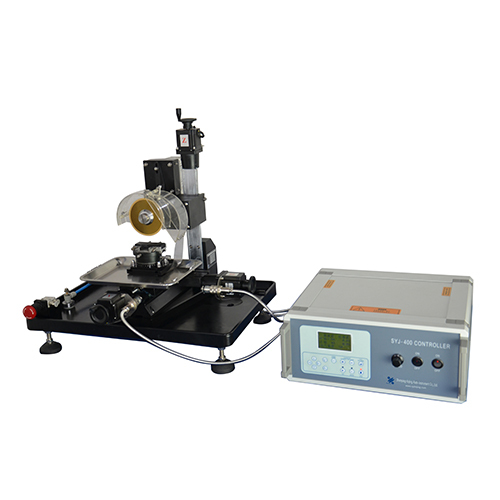

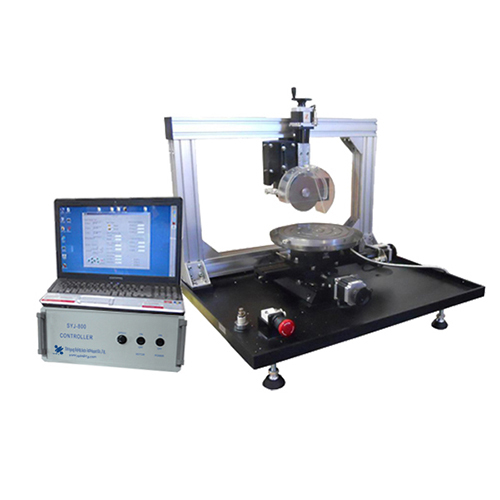

Precision Dicing Saw With 12 Inches Round And 280mm Square Workbench

1. The precision cutting saw is suitable for processing large-size samples, with a maximum processing size of φ12 and a standard imported 2.4KW high-torque spindle;

2. The precision cutting saw can be equipped with optional non-contact height measurement (NCS); optional blade breakage detection (BBD);

3. The θ axis of the precision cutting saw uses a direct-drive DD motor with high precision and high speed;

- Shenyang Kejing

- Shenyang, China

- 50 sets

- Information

Introduction of precision wafer dicing saw:

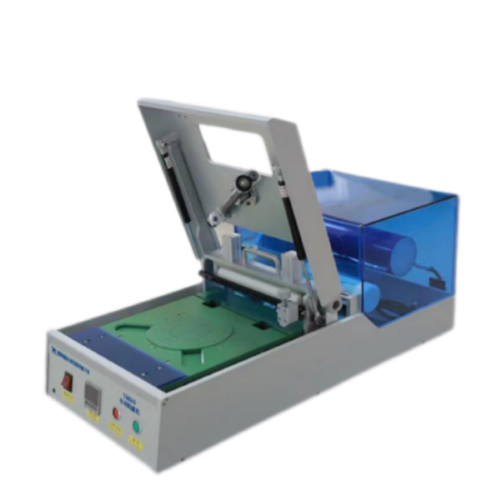

Precision wafer dicing saw is used for 12-inch silicon wafers, LED packaging, QFN, DNF, BGA, optical optoelectronics, communications, PCB, ceramics, glass, lithium niobate, alumina, quartz, etc.Precision cutting saw size: Φ12 or 280mm. Cutting depth: ≦4mm or customized.Precision cutting saw is equipped with two sets of high-power and low-power microscope systems. Laboratory saws realizes high-speed image recognition function, multiple alignment modes, and fast edge search, which greatly improves efficiency.

Technical parameters of laboratory saws:

Product name | SYJ-3310 precision dicing saw | |

model of laboratory saws | SYJ-3310 | |

Application of laboratory saws | 12-inch silicon wafer, LED sealing, QFN, DNF, BGA, optical optoelectronics, communication, PCB, ceramics, glass, lithium niobate, aluminum oxide, quartz | |

project | Parameters (specification) | |

Configuration performance | machining size | Φ12 or 280mm |

Grooving depth | ≦4mm or customized | |

Spindle | Rotation speed | 6000~60000rpm |

Output power | DC 2.4W | |

X-axis | Outting distance | Max 280mm |

Speed setting range | 0.1~500mm/s | |

Y-axis | cutting distance of laboratory saws | Max 280mm |

Single-step stepping accuracy | ≦0.003mm/5mm | |

Max tolerance of the whole travel distance | ≦0.005mm/280mm | |

Z-axis | Effective cutting distance of precision wafer dicing saw | Max 40mm |

Repeatable positioning accuracy | 0.001mm | |

Blade working size | φ50mm~φ60mm | |

Θ-axis | Rotation angle range | 320° |

Resolution of precision wafer dicing saw | 0.0002° | |

Alignment system | light source + ring light + industrial camera | |

Display of precision wafer dicing saw | Industrial grade 15” color LCD touch screen | |

Operating system | Control system | PC Base+Windows |

Operating system | Windows, language Chinese | |

Conditions of use | Power supply | single-phase, AC380±5%, 4.0kVY |

Compressed air | pressure 0.5~0.6Mpa, Max consumption 260L/min | |

Cutting liquid | pressure 0.5~0.6Mpa, Max consumption 4.0L/min | |

Coolant water | pressure 0.2~0.3Mpa, Max consumption 1.5L/min | |

Ventilation | 5.0m3/min(ANR) | |

Ambient temperature | 20~25℃ | |

Humidity | <80% | |

1. Please set the machine in the environment of 20~25°C (the fluctuation range is controlled within ±1°C); the indoor humidity should be less than 80% without condensation. 2. Please use clean compressed air with atmospheric pressure dew point below -15℃, residual oil content of 0.1ppm and filtration degree above 0.01um/99.5. 3. Please control the temperature of the cutting liquid at room temperature + 2°C (the fluctuation range is within ±1°C), and the temperature of the coolant water should be controlled at the same as room temperature (the fluctuation range is controlled within ±1°C). 4. Please avoid the impact of gravity and any external vibration threat to the device. In addition, do not install the equipment near blowers, vents and devices that generate high temperatures and oil/grease dirt. 5. Install the device on a waterproof ground and a location with smooth drainage. | ||

Installation parameter of precision cutting saw | dimension (W×D×H) | 910mm×1100mm×1860mm |

weight | 1500kg | |

Logistics of laboratory saws:

About us:

Our laboratory saws are widely praised for their high precision, strong stability and long service life. We are well aware that the quality of laboratory saws directly affects the production efficiency of customers, so we always insist on using the best quality materials and the most advanced manufacturing technology to ensure that each laboratory saw can meet the stringent requirements of customers.