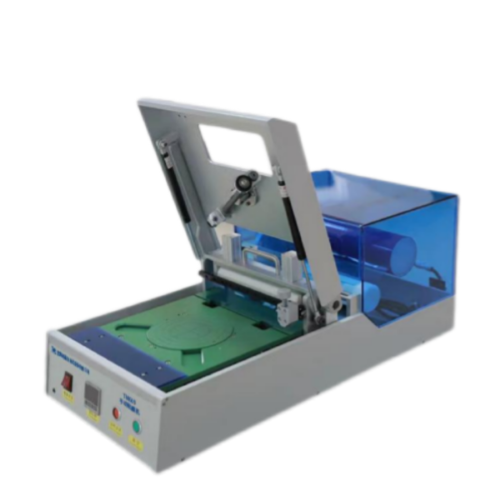

Manual Wafer Mounter For Cutting

1.Manual frame film mounter is suitable for blue film, UV film, PET substrate film and other single/double-layer films.

2.Manual frame film mounter is suitable for MODTF2 series frames.

3.Manual frame film mounter is equipped with anti-static Teflon treated working plate to effectively protect the chip.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Introduction of manual wafer mounter:

TM series manual wafer mounter is specially used for wafer (thin slice), QFN, glass, substrate, etc. before cutting. It is equipped with precision guide rails and imported temperature control system. The overall performance of manual wafer mounter is stable and the operation is convenient and fast.

Advantages of manual frame film mounter:

1. The working plate of manual wafer mounter has heating function, which makes the film more adhesive.

2. The working plate height of manual wafer mounter is elastic, which can adapt to products of different thicknesses.

3. The pressure of the roller can be adjusted by adjusting the air pressure, constant and controllable, and numerical display.

4. Equipped with circular knife and cross-cutting knife, imported blades are used, and the service life is longer.

5. The upper cover is supported by hydraulic spring, which is labor-saving and safe to operate.

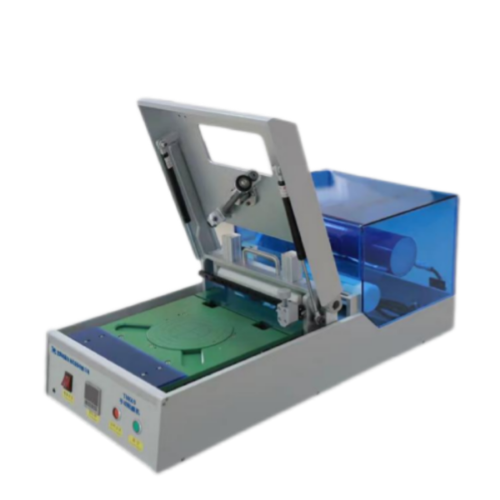

Technical parameters of wafer mounter:

Product name | Manual Wafer Mounter TM600 |

Product model | TM600 |

| Main parameters | 1. Rated power supply: AC220V, 50Hz. 2. Rated power: 0.7KW. 3. Applicable size: 6 inches and below. 4. Film paste error: ±1mm. 5. Compressed air: 0.5-0.7Mpa. 6. Air flow: ≤46L/min. 7. Film cutting method: cross-cutting or circular cutting. 8. Overall dimensions: 740x350x290mm. 9. Weight: 50Kg. 10. Applicable film: single-layer blue film, double-layer UV film. 11. Film paste method: manual. 12. Work surface: Teflon treatment, protect the workpiece. 13. Production capacity: 60pcs/h (theoretical value). |

FAQ:

1.Is the film sticking error of ±1mm the limit error of the machine, or is it determined by the operation method? Can it be further optimized?

The film sticking error of ±1mm mainly comes from the uncertainty in the manual operation process. The error can be effectively reduced through strict operation procedures and skilled operators. The film sticking accuracy of the machine itself has been optimized as much as possible.

About us:

Shenyang Kejing's factory is located in Shenyang City, Northeast China, covering an area of 14,000 square meters. It integrates R&D, design, production, testing, packaging and after-sales service, and has a complete production chain. The production area is 2,818 square meters, with advanced equipment to efficiently produce high-quality products; the warehouse area is 2,908 square meters, ensuring adequate storage of finished products and raw materials and supporting efficient logistics management. Welcome to visit our factory!