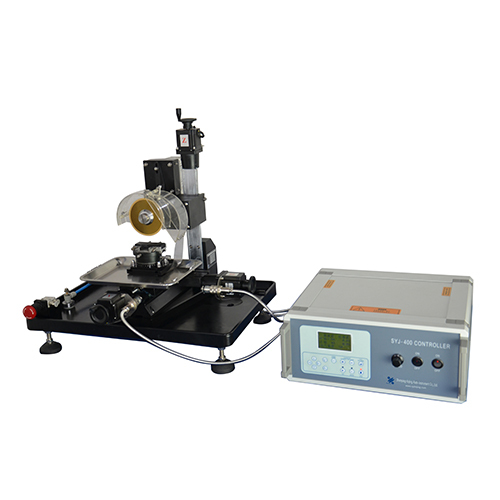

Precision CNC Dicing Saw

1. Precision Slicing Machine driven by a stepper motor, it has a fast cutting speed and runs smoothly, ensuring accurate cutting of various materials.

2. Precision Slicing Machine allows users to program themselves and easily perform complex cutting operations, suitable for a variety of materials such as crystals, ceramics, and glass.

3. Precision Slicing Machine with a waterproof cover to prevent splashing, and can be connected to an external circulating water cooling system to protect samples from high temperatures

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Description of Dicing Saw:

Precision Slicing Machine is a continuous cutting equipment and can be programmable by computer. It is mainly suitable for dicing, grooving and cutting of crystals, ceramics, glass and various slice materials as well as ore and metal, etc. Precision Slicing Machine can dice and cut materials up to 200mm in diameter, 10mm in depth. Precision Slicing Machine adopts stepper motor for drive with a cutting accuracy of up to 0.02mm.

Main Features of :

· Computerized control, Precision Slicing Machine allowing users to program sample cutting by themselves

· A large-torque AC brushless motor of 3000rpm is adopted to drive the spindle and adjusting rotating speed 0- 3000rpm through speed regulating buttons

· The Dicing Saw rotating workbench can automatically / manually rotate 360° with tolerance of ±0.02°, which is easy to operate.

· The saw is equipped with precision vacuum chuck of 8'' with 200mm OD of wafers. Precision Dicing Saw uses a Ø220mm sample holding plate and the cutting distance is up to 200mm×200mm.

· Proper blade and blade clamps can be selected according to the size of materials

Technical Parameters of Dicing Saw:

Product Name | SYJ-800 CNC Dicing / Cutting Saw | ||

Product Model | SYJ-800 | ||

Dicing Saw Installation conditions | 1. Dicing Saw temperature and humidity: 10-85%RH (at 25℃ without condensation) Temperature: 0-45℃. 2. There is no strong vibration source and corrosive gas around the equipment. 3. Dicing Saw power supply: AC110V 60Hz American standard three-pole socket (customized machine) AC220V 50Hz national standard three-pole socket 4. Cooling water: The Dicing Saw is equipped with an inlet and a drain, and you need to connect the tap water and drainage device by yourself 5. Dicing Saw air source: no requirement for standard equipment 6. Workbench: Dicing Saw size 800mm×600mm×700mm, Dicing Saw load-bearing more than 50kg 7. Dicing Saw Ventilation device: good ventilation environment, no special ventilation device requirements | ||

Precision Wafer Saw Major Parameters (Specification) | 1. Wafer Saw power supply port: AC220V 50Hz 10A 2. Wafer Saw spindle speed: 0-3000rpm stepless speed regulation 3. Wafer Saw spindle drive power: 180W 4. X-axis slide stroke: 200mm 5. Y-axis slide stroke: 200mm 6. Z-axis slide stroke: 55mm 7. Processable dicing depth: 1.3mm 8. Wafer Saw max cutting depth: 10mm 9. X/Y/Z-axis drive motor: high-precision stepper motor 10. Stepper motor positioning accuracy: 0.01mm 11. Wafer Saw workbench angle and error: 360°±0.02° 12. Wafer Dicing Machine Carrier plate diameter: Glass: φ220mm 13. Wafer Dicing Machine Vacuum suction cup diameter: φ203.2mm (8 inches) 14. Wafer Dicing Machine Saw blade size: Outer diameter: Ø100/Ø150mm Inner diameter: Ø12.7mm 15. Wafer Saw host control method: Computer program (USB) | ||

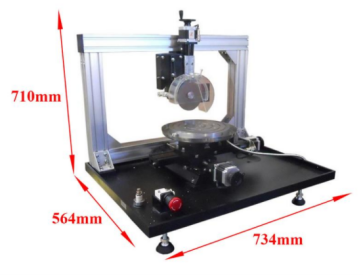

16. Precision Wafer Saw specifications: ·Wafer Saw Size: 700mm×530mm×710mm ·Wafer Saw Weight: ≈55kg |  | ||

Precision Dicing Saw Notes: 1. Precision Dicing Saw domestic standard power supply of the equipment is AC220V 50Hz. Precision Dicing Saw actual power supply parameters are subject to the label attached to the back of the product. 2. Precision Dicing Saw supports customized AC110V 60Hz power supply equipment. 3. To use this Precision Dicing Saw , you need to bring your own computer as the device control host. The device comes with a "U disk installation program". | |||

Wafer Dicing Machine Standard Accessories:

No. | name | qty | picture |

1 | Saw Pads | 4 sets in total |

|

2 | Glass Tray | 1 set | |

3 | Resin Ceramic Blocks | 2 pieces | |

4 | Full Sintered Diamond Blade (Ø100mm×Ø12.7mm×0.33mm) | 1 piece | |

5 | Electroplated Diamond Blade (Ø100mm×Ø12.7mm×0.4mm) | 2 pieces | |

6 | Sintered Diamond Scribing Blade (Ø86mm×Ø70mm×0.15mm) | 1 piece | |

7 | Wax Bar | 4 pieces | |

8 | Dicing Blade Clamp | 1 set | |

9 | Goggles | 1 pair |

|

| 10 | Oilless Vacuum Pump | 1 set |

|

Wafer Dicing Machine Optional Accessories:

No. | name | functional type | picture |

1 | Fully Sintered Diamond Blade Ø100mm×Ø12.7mm×0.35mm | (optional) |

|

2 | Edge Sintered Diamond Saw Blade Ø100mm×Ø12.7mm×0.4mm, | (optional) |

|

3 | Sintered Diamond Dicing Scribing Blade Ø86mm×Ø70mm×0.15mm | (optional) | |

4 | MTI series heating platform | (optional) |  |

Warranty:

· One year limited with lifetime support (not including rusted parts due to inadequate storage conditions)

Logistics:

About Us:

Shenyang Kejing Auto-instrument Co., Ltd. was established in May 2000. Shenyang Kejing has been keeping the goal of leading the trend in the field of material analysis equipment. Up to now, the company has hundreds of products covering material cutting, grinding, polishing, film coating, mixing, rolling & pressing, sintering, analyzing and other fields as well as related consumables, which can meet the requirements on complete sets of sample preparation and analysis for crystal, ceramics, glass, rock, mineral, metal materials, refractory materials, composite materials, and biological materials.