Medical Grinder Equipment

1. The polishing machine for medical applications provides a fully automated grinding process, and the grinding thickness can be digitally monitored in real time to ensure high precision and consistency, suitable for various microscopic analysis requirements.

2. The polishing machine for medical applications has a pressure regulation function, safe and stable operation, no noise, and easy replacement of consumables, which improves the user's operating experience and equipment maintenance efficiency.

3. Our polishing machine for medical applications has professional technicians with many years of experience who can answer your questions and provide remote teaching.

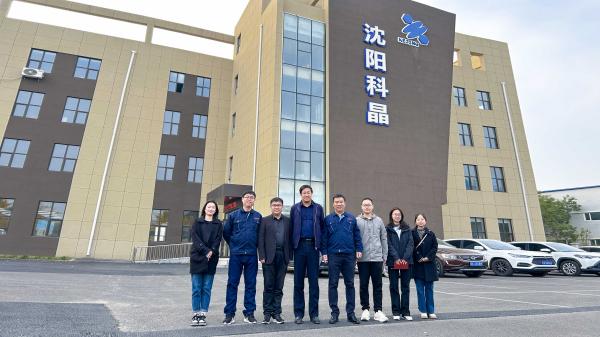

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

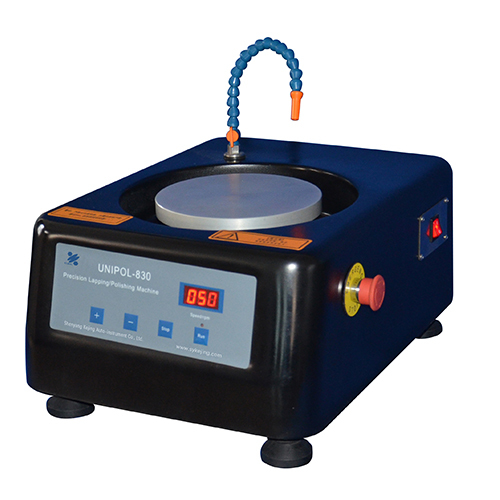

Introduction of high precision polishing machines:

UNIPOL-1204 automatic high precision polishing machines are suitable for grinding medical hard tissue slices, especially for grinding and polishing medical tissue slices with embedded materials (metal, ceramic, plastic, mineral, etc.).

Main features of high precision polishing machines:

1. High precision polishing machines can realize automatic grinding, and the grinding thickness can be monitored digitally in real time during the grinding process.

2. Medical polishing machine can grind and modify the bonding surface of embedded samples to make them flat and prepare for thin slice cutting.

3. Medical polishing machine can grind and polish thin slices to meet the requirements of staining and other microscopic analysis.

4. Medical polishing machine has extremely high flatness and precision.

5. The pressure of medical polishing machine can be adjusted and the thickness can be detected in real time.

6. Medical grinding and polishing machine is safe and stable, no noise, and easy to replace accessories and consumables.

Technical parameters of medical grinding and polishing machine:

Product name | UNIPOL-1204 Automatic Precision Grinding Machine |

Product model | UNIPOL-1204 |

| Main parameters | 1. Power supply: 220V, 500W (excluding vacuum pump) 2. Minimum thickness of grinding disc: ≤10μm. 3. Maximum size of grinding disc: 100×50mm. 4. Initial thickness of disc: ≤1㎜. 5. Digital display accuracy: 1μm. 6. Feeding method: gravity feeding (feeding amount ≤0.001mm). 7. Grinding disc speed: 10-200rpm. 8. Sample table swing gear: 20 gears (20 swing speeds). 9. Grinding disc diameter: 300mm (diamond grinding disc or sandpaper can be replaced with 400#, 600#, 800#, 1000#, 1500#). 10. Counterweight: 450g. 11. Sample fixing method: glass slide vacuum. adsorption. 12. Equipment size: 652×700×640mm. 13. Equipment weight: 70k. |

About us:

In terms of team building, the team has very strict requirements for product design. The company has reached a long-term cooperation with a professional logistics company. Our product logistics and packaging team provides all-round guarantee for product production and global transportation. In addition, our laboratory facilities are complete and open to all customers for product experience. We also provide professional technical training and guidance to ensure that every customer can get the most value from our products. We welcome you!