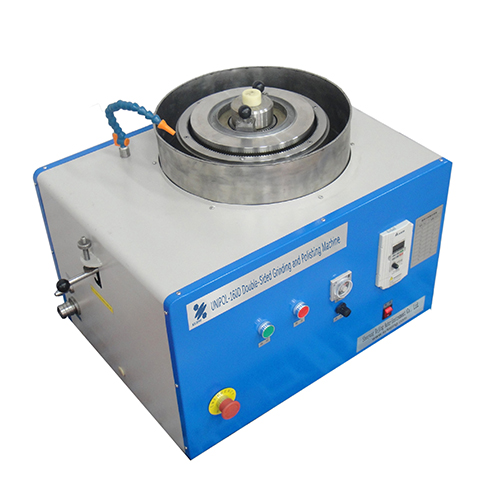

Bench Top Double Side Lapping And Polishing Machine

1.Double sided precise lapping machine can achieve the rotation of the upper, middle and lower axes at different speeds and directions through the worm gear reducer and gear set, so that the double-sided surface of the sample can be evenly ground.

2.Double sided precise lapping machine can process multiple samples at the same time, with high grinding and polishing efficiency, saving time and cost.

3.Double sided precise lapping machine can perform double-sided thinning of thin slices.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Introduction of dual face lapping and polishing machines:

Dual face lapping and polishing machines are mainly used for double-sided precision grinding and polishing of quartz wafers, sapphire, ceramics, glass, infrared optical materials (such as zinc selenide, zinc sulfide, silicon, germanium and other crystals), metals and other sheet materials. Dual face lapping and polishing machines use worm gear reducers as transmission mechanisms, and achieve the rotation of the upper, middle and lower axes at different speeds and directions through gear sets, so that the upper and lower grinding and polishing discs and the middle sun gear have speed differences and relative motions, and the sample is placed in the inner hole of the sample-carrying planetary gear driven by the sun gear, so as to perform double sided grinding and polishing. Dual face lapping and polishing machines can choose to grind samples with a grinding disc and abrasive, or with a polishing disc and sandpaper. Polishing disc and sandpaper means sticking sandpaper on the polishing film and then adsorbing the polishing film on the polishing disc for grinding and polishing. Double sided lapping machine can grind multiple samples at the same time, with high efficiency of grinding and polishing, suitable for grinding a large number of samples or small batch production in factories.

Main features of double sided lapping machine:

1. The speed of the double sided lapping machine is controlled by manually adjusting the frequency of the inverter.

2. The lapping and polishing machine can perform double-sided grinding and polishing on 4 substrates with a maximum of ø2" at the same time.

3. The lapping and polishing machine can perform double-sided thinning of thin slices.

4. The double sided lapping machine is an ideal tool for double-sided grinding and polishing of si, ge, and oxide single crystal substrates.

Technical parameters of double sided lapping machine:

Product Name | UNIPOL-160D Double-Sided Grinding and Polishing Machine / Lapping Machine |

Product Model | UNIPOL-160D |

Installation Conditions | 1. Temperature and humidity: 10-85%RH (at 25℃ without condensation) Temperature: 0-45℃. 2. There is no strong vibration source and corrosive gas around the Double-sided precise lapping machine. 3. Power supply: Single phase: AC220V 50Hz National standard three-pole socket 10A, must be well grounded. 4. Cooling water: Double-sided precise lapping machine is equipped with water inlet and outlet, need to connect tap water and drainage (circulating water tank) by yourself. 5. Air source: standard equipment has no requirements. 6. Auxiliary equipment: can be used with our SKZD-2/3 series dripper (purchased separately). 7. Workbench: recommended size: L800mm x W650mm x H700mm, load-bearing more than 150kg. 8. Ventilation device: good ventilation environment, no special ventilation device requirements. |

Main Parameters (Specification) | 1. Input voltage: single phase: AC220V/50Hz. 2. Total power: 550W. 3. Grinding and polishing disc diameter: Φ240 mm. 4. Grinding and polishing disc speed: effective value: 5-65rpm. (stepless speed regulation). 5. Upper limit of sample diameter: Ø50mm. 6. Upper limit of sample thickness: 15mm. 7. Upper grinding and polishing disc weight: 2.5kg. 8. Upper grinding and polishing disc counterweight ring weight: 1.3kg/1.6kg/2kg. 9. Control mode: button + timed operation (countdown). |

Product Dimension and Weight | 10. Specifications of double sided lapping machine: Dimensions: L700mm x W550mm x H600mm. Net weight: about 80kg.

Note: The power supply of Dual face lapping and polishing machines is domestic standard AC220V 50Hz. The actual power supply is subject to the parameters on the rear label of the product. |

Standard accessories:

No. | Name | Qty | Picture |

1 | Grinding / Lapping Plate | 1 pcs |

|

2 | Polishing Plate | 1 pcs |  |

3 | Condition Planetary Pinion | 1 pcs | - |

4 | Sample Holding Planetary Pinion (bakelite) | 1 pcs | - |

5 | Balancing Ring | 1 pcs |  |

6 | Magnetic Sheet | 2 pcs |

|

7 | (Steel) Lapping Buffer Sheet | 2 pcs |

|

8 | Polishing Pad (Nubuck Leather, Synthetic Leather, Polyurethane) | 1 pcs each |  |

9 | Diamond Polishing Paste (W2.5) | 1 pcs |

|

Optional accessories:

No. | Name | Functional type | Picture |

1 | Sample Holding Pinion with different holes can be made according to user's needs. | (Optional) | - |

Warranty:

One year limited with lifetime support (not including rusted parts due to inadequate storage conditions).

Logistics:

About us:

Shenyang Kejing focuses on providing high-quality scientific research services to universities, scientific research institutes and manufacturing enterprises. Our double sided lapping machine provides comprehensive after-sales service guarantees and has professional logistics capabilities to ensure that products can be delivered safely and on time. Promoting social progress with innovative technology is our unremitting pursuit. We always adhere to the customer-centered service concept and are committed to providing customers with excellent double sided lapping machine and service experience.