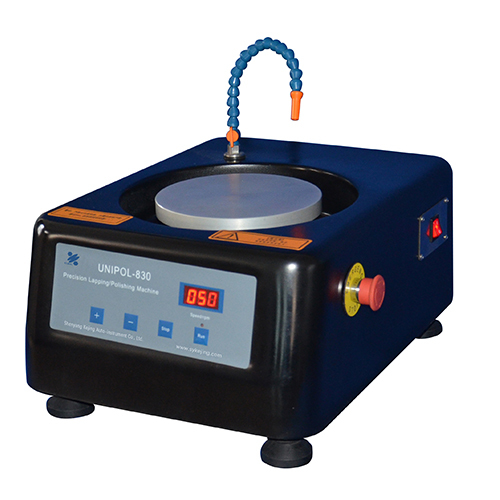

Automatic precision grinding and polishing machine

1. The grinding and polishing machine is new and has a high-precision design to meet your needs.

2. The grinding and polishing machine has a good use effect and a first-class grinding effect.

3. With its own factory, the grinding and polishing machine has well-designed details, is precise and efficient.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Introduction of automatic grinding and polishing machine:

UNIPOL-1502AT Automatic grinding and polishing machine is an efficient and multi-functional precision equipment. Automatic grinding and polishing machine is widely used for surface grinding and polishing of various materials. The whole machine is equipped with a Ø381mm high-precision grinding and polishing disc and three independent processing stations, which can stably process flat samples with a diameter of ≤Ø110mm. The Automatic grinding and polishing machine can fully meet the strict requirements of laboratory and industrial users for sample surface quality.

Automatic grinding and polishing machine supports flexible combination with a variety of auxiliary equipment to obtain high-quality grinding surfaces, and can also achieve precision grinding and polishing of special samples such as wafers. The core swing arm mechanism of the Automatic grinding and polishing machine simulates manual operation, drives the sample tray to swing smoothly left and right, and combines the compound motion of rotation and revolution to effectively improve the traditional problems such as sample center protrusion and edge over-grinding, greatly improving the processing uniformity and finished product consistency of the product.

The grinder polisher machine is equipped with a professional sample tray with high flatness and high parallelism to ensure that the sample surface is flat and smooth, and the edge has no chamfers. It is especially suitable for precision processing scenarios with high standards for edge integrity. UNIPOL-1502AT grinder polisher machine is an ideal grinding and polishing solution for experimental research and development, high-end manufacturing and other fields.

Advantages of grinder polisher machine:

1. High-precision polishing disc:

The flatness is less than 0.0025mm per 25mm×25mm, ensuring the extreme flatness of the sample surface.

2. Stable rotation system:

The grinder polisher machine adopts a high-precision rotating axis, and the tray end jump is controlled within 0.012mm, which runs smoothly and ensures processing consistency.

3. Three-station synchronous processing:

The grinder polisher machine is equipped with three processing stations (including driving wheels), which can process multiple samples at the same time, which is efficient and convenient.

4. Stepless speed regulation + digital display control:

The spindle speed of the grinder polisher machine is adjustable, with digital display, intuitive operation and controllable accuracy.

5. Intelligent timing function:

The grinder polisher machine has a built-in timer (0-300 hours) to accurately control the grinding and polishing time and improve the level of automation.

6. Support automatic liquid supply system:

The grinder polisher machine can be equipped with an automatic dripper or circulation pump to make the grinding and polishing operation more worry-free and efficient.

Technical parameters of grinder polisher machine:

| Product name | UNIPOL-1502AT automatic precision grinding and polishing machine |

| Product model | UNIPOL-1502AT |

| Installation conditions | 1. Environmental requirements: temperature and humidity 10~85%RH (25℃ without condensation), temperature 0~45℃. 2. Installation conditions: There should be no strong vibration source and corrosive gas around the equipment. 3. Cooling system: The equipment is equipped with a water inlet and a water outlet, and you need to connect the tap water and drainage pipelines by yourself. 4. Power requirements: Export version: AC110/240V, 50/60Hz, three-pole socket, 10A. Domestic version: AC220V, 50Hz, national standard three-pole socket, 10A. The socket must have good safety grounding. 5. Air source requirements: Standard equipment has no air source requirements. 6. Installation requirements: It is recommended to install on a workbench or desktop with a load-bearing capacity of more than 150kg. 7. Ventilation requirements: Good ventilation environment, no special ventilation device requirements. 8. Recommended auxiliary equipment (need to be purchased separately). · HEATER-3040 or 250 heating platform. · SKCH-1 precision thickness gauge. · GPC series precision grinding and polishing controller (manipulator). · SZKD series dripper. · SKCS-1 blow dryer. |

| Main parameters | 1. Power interface: AC110/220V switchable (domestic AC110V Invalid). 2. Total equipment power: 405W. 3. Grinding and polishing disc diameter: Ø381 mm. 4. Sample tray diameter: Ø110 mm. 5. Processing station: 3 stations, including swing mechanism. · Driving wheel speed: 0~80 rpm. 6. Sample tray swing speed: 0~9 times/min (stepless speed regulation). 7. Spindle drive motor: DC110V/375W. 8. Grinding and polishing disc speed: 10~125 rpm (stepless speed regulation). 9. Control mode: timed operation (countdown). 10. Product specifications: · Dimensions: L620mm×W740mm×H440mm; · Weight: ≈95Kg. |

Standard accessories:

| NO. | Name | Qty | Picture |

| 1 | Cast iron grinding disc | 1pcs |  |

| 2 | Cast aluminum polishing disc | 1pcs |  |

| 3 | Carrying disc | 3pcs |  |

| 4 | Repairing ring | 3pcs |  |

| 5 | Polishing pad (nubuck, synthetic leather, polyurethane) | One piece each |  |

| 6 | Corundum grinding powder | 0.5kg |  |

| 7 | Paraffin wax stick | 4 pcs |  |

Optional accessories:

| NO. | Name | Functional category | Picture |

| 1 | SKZD-2 dripper | (Optional) |  |

| 2 | SKZD-3 dripper | (Optional) |  |

| 3 | SKZD-4 automatic dripper | (Optional) |  |

| 4 | SKZD-5 dripper | (Optional) |  |

| 5 | YJXZ-12 mixing circulation pump | (Optional) |  |

| 6 | Precision thickness gauge | (Optional) |  |

| 7 | GPC-50A precision grinding and polishing controller | (Optional) |  |

| 8 | Glass grinding disc | (Optional) |  |

| 9 | Magnetic resin diamond grinding disc | (Optional) |  |

| 10 | Wax-free polishing disc | (Optional) |  |

Warranty:

One year limited with lifetime support (not including rusted parts due to inadequate storage conditions).

Logistics:

About us:

We are not only an equipment supplier, but also a provider of scientific research services. We serve the society with innovative technology, always put customers' needs first, and are committed to providing customers with the best solutions. We pursue excellence and strive to become a well-known brand of domestic materials analysis instruments and win respect and trust in the international market. When you choose Shenyang Kejing, you will choose a dynamic and progressive partner.