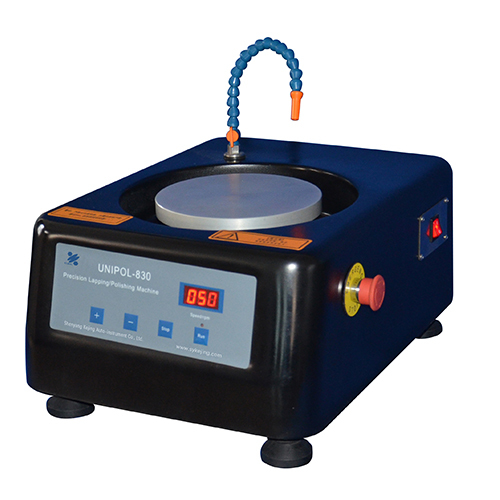

8" Precision Lapping And Polishing Machine

1. The automatic precision grinding and polishing machine is equipped with two processing stations, which can swing left and right during the grinding process, and the surface quality after grinding is uniform.

2. The automatic precision grinding and polishing machine is equipped with a high-flatness and parallelism precision cylindrical load block, which is particularly suitable for samples with high edge requirements.

3. The automatic precision grinding and polishing machine supports two grinding methods: Grinding disc plus abrasive and polishing disc with sandpaper, which can be easily replaced quickly.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Introduction of automatic precision polishing machine:

The precision lapping and polishing machine is suitable for grinding and polishing samples of crystals, ceramics, metals, glass, rock samples, mineral samples, PCB boards, infrared optical materials (such as zinc selenide, zinc sulfide, silicon, germanium and other crystals), refractory materials, composite materials and other materials. The precision lapping and polishing machine is one of the ideal grinding and polishing equipment for scientific research and production experiments. The precision lapping and polishing machine is equipped with a Ø203mm grinding and polishing disc and two processing stations, which can be used for grinding and polishing planes ≤Ø80mm. During the grinding process, the two processing stations of the precision lapping and polishing machine can swing left and right at a certain frequency, and at the same time push the carrier block to swing left and right. The carrier block rotates while revolving with the grinding disc, so that the sample moves irregularly, and the surface quality of the sample after grinding is uniform. The carrier block equipped with the automatic precision polishing Machine is a precision cylindrical metal block with high flatness and parallelism, so that the surface of the sample after grinding also has high flatness, and the edge of the sample will not be chamfered, which is especially suitable for samples with high edge requirements. Automatic precision polishing machine can mass produce high-quality surface polishing products if equipped with appropriate accessories (GPC-50A precision grinding and polishing controller). GPC-50A precision grinding and polishing machine can strictly control the flatness and parallelism of the sample being ground. Automatic precision polishing machine can grind samples by grinding disc plus abrasive, or by polishing disc with sandpaper. Sandpaper or polishing pad is clamped by magnetic adsorption, which is convenient for loading and unloading. Whether to use sandpaper or abrasive can be selected according to the material of the sample being ground.

Main features of automatic precision polishing machine:

1. Ultra-flat polishing disc (flatness less than 0.0025mm per 25mm×25mm).

2. Ultra-precision rotating spindle (pallet end runout less than 0.01mm).

3. The precision lapping and polishing machine has two processing stations.

4. The spindle rotation of the precision lapping and polishing machine adopts stepless speed control, and the real-time speed is displayed digitally.

5. The precision lapping and polishing machine is equipped with a timer to accurately control the working time (between 0-300h).

6. The precision lapping and polishing machine can be equipped with an automatic slurry feeder or a circulation pump to make grinding and polishing more convenient and quick.

Technical parameters of automatic precision grinding and polishing machine:

Product Name | UNIPOL-802 Automatic Precision Grinder / Polisher (Lapping and Polishing Machine) |

Product Model | UNIPOL-802 |

Installation Conditions | 1. Temperature and humidity: 10-85%RH (at 25℃ without condensation) Temperature: 0-45℃. 2. There is no strong vibration source and corrosive gas around the Automatic precision polishing machine. 3. Power supply: Export standard equipment: AC110/240V 50/60Hz three-pole socket 10A. 4. Domestic standard equipment: AC220V 50Hz national standard three-pole socket 10A (the socket must have a good safety protection grounding wire). 5. Cooling water; the equipment is equipped with a water inlet and a water outlet, and you need to connect the tap water and drainage pipelines by yourself. 6. Air source; standard equipment is not required. 7. Workbench; it is recommended to use it on an operating table or desktop with a load-bearing capacity of more than 150kg. 8. Ventilation device; good ventilation environment, no special. ventilation device requirements. 9. Auxiliary equipment (purchased separately): Recommended: 1. HEATER-3040 or 250 heating platform. 2. SKCH-1 precision thickness gauge. 3. GPC-series precision grinding and polishing controller (manipulator). 4. SZKD-series dripper. 5. SKCS-1 blow dryer. |

Main Parameters (Specification) | 1. Automatic precision polishing machine power supply port: AC110/220V conversion (domestic AC110V is invalid). 2. Total power: 275W. 3. Grinding and polishing plate diameter: Φ203 mm. 4. Sample plate diameter: Φ80 mm. 5. Number of stations (swing mechanism): 2 stations. 6. Sample plate swing speed: 0-9 times/min (stepless speed regulation). 7. Spindle drive motor: DC110V 245W. 8. Grinding and polishing plate speed: 10-250rpm (stepless speed regulation). 9. Control mode: timed operation (countdown). |

Product Dimension and Weight | Dimensions: L470×W570×H400mm. Weight: ≈68Kg.

|

Standard accessories:

No. | Name | Qty | Picture |

1 | Cast Iron Polishing Plate | 1 pcs |

|

2 | Cast Aluminum Polishing Plate | 1 pcs |  |

3 | Sample Holder / Sample Holding Plate | 2 pcs |  |

4 | Condition Ring | 2 pcs |  |

5 | Polishing Pad (Nubuck Leather, Synthetic Leather, Polyurethane) | 1 pcs each |

|

6 | Corundum Grinding Powder | 0.5kg |

|

7 | Wax Bar | 4 pcs |

|

Optional accessories:

No. | Name | Functional type | Picture |

1 | SKZD-2 Slurry Feeder | (Optional) |

|

2 | SKZD-3 Slurry Feeder | (Optional) |

|

3 | SKZD-4 Automatic Slurry Feeder | (Optional) |

|

4 | SKZD-5 Slurry Feeder | (Optional) |

|

5 | YZXZ-12 Stirring Circulation Pump | (Optional) | |

6 | Precision Thickness Gauge | (Optional) | |

7 | GPC-50A Precision Polishing Fixture | (Optional) | |

8 | Ceramic Lapping Plate | (Optional) | |

9 | Glass Lapping Plate | (Optional) | |

10 | Magnetic Resin Diamond Polishing Disc | (Optional) | |

11 | Wax-Free Lapping Plate | (Optional) |

|

Warranty:

One year limited with lifetime support (not including rusted parts due to inadequate storage conditions).

Logistics:

About us:

We have won the trust of customers around the world with our excellent product quality and spirit of continuous innovation. We are well aware that the performance of automatic precision grinding and polishing machine depends not only on design and manufacturing, but also on subsequent maintenance. To this end, we not only provide high-quality equipment, but also provide customers with detailed user guides and maintenance manuals to help customers better use and maintain the equipment and extend the service life of the equipment.