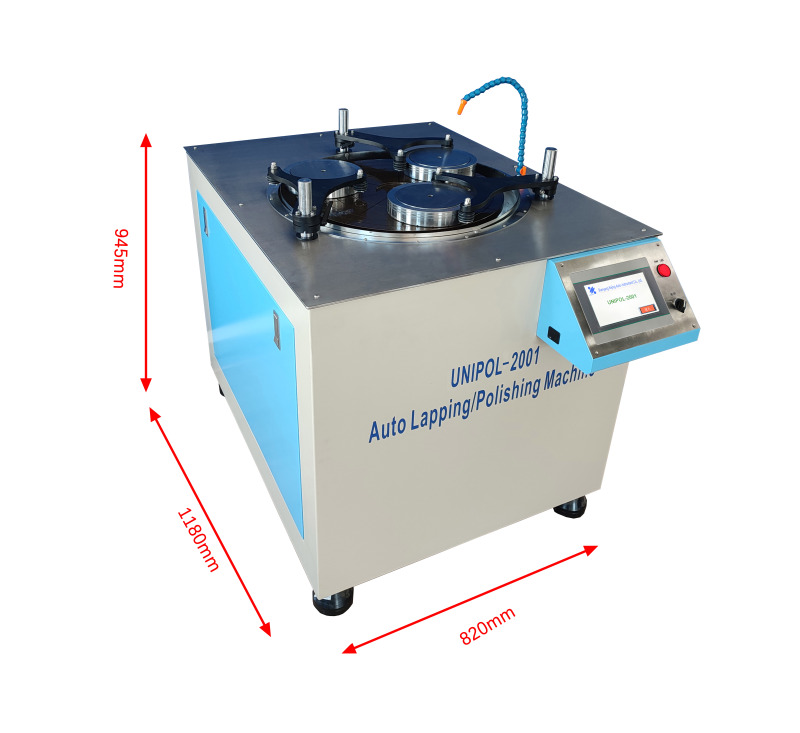

20" Precision Polishing Machine

1. Automatic floor-standing laboratory grinding polishing machine, suitable for plane thinning and polishing of large-sized materials such as 6 inches and 8 inches.

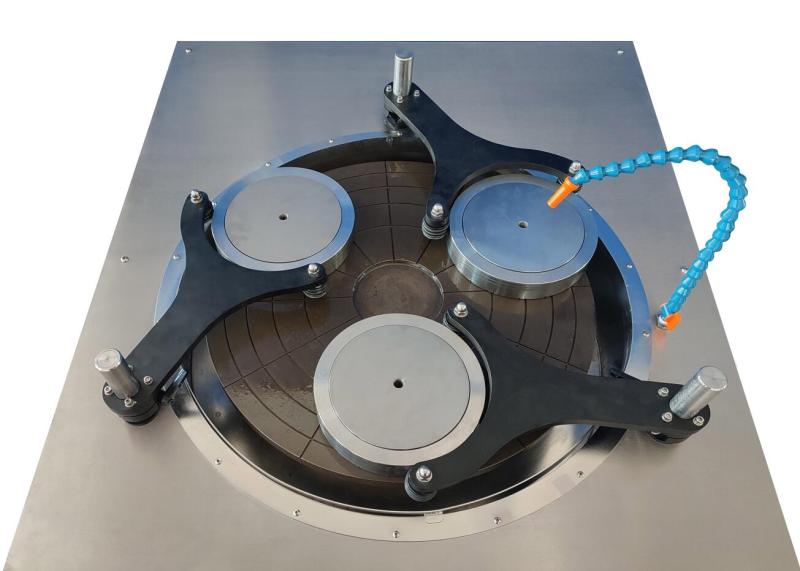

2. The laboratory grinding polishing machine has three processing stations to ensure uniform surface quality of the sample after grinding.

3. The laboratory grinding polishing machine can make the sample surface have high flatness and will not chamfer the edge of the sample.

- Shenyang Kejing

- Shenyang, China

- 44 working days

- 50 sets

- Information

- Video

Introduction of laboratory polishing machine for metal:

UNIPOL-2001 precision grinding and polishing machine has three processing stations. It is a floor-standing grinding and polishing machine that can grind and polish large-size samples. It is used for grinding and polishing samples of crystals, ceramics, metals, glass, rock samples, mineral samples, PCB boards, infrared optical materials (such as zinc selenide, zinc sulfide, silicon, germanium and other crystals), refractory materials, composite materials and other materials. Laboratory precision polishing machine is one of the ideal grinding and polishing equipment for scientific research and production experiments. The laboratory precision polishing machine is equipped with a Ø508mm grinding and polishing disc and three processing stations. It can be used for grinding and polishing discs ≤Ø160mm or rectangular planes with a diagonal length of ≤160mm. During the grinding process, the three processing stations of the laboratory precision polishing machine can swing left and right at a certain frequency, and at the same time drive the carrier block to swing left and right. The carrier block rotates while revolving with the grinding disc, so that the sample moves irregularly, and the surface quality of the sample after grinding is uniform. The load block of the laboratory precision polishing machine is a precision cylindrical metal block with high flatness and parallelism, so that the surface of the sample after grinding also has high flatness, and the laboratory precision polishing machine will not chamfer the edge of the sample, which is especially suitable for samples with high edge requirements. If the laboratory polishing machine for metal is equipped with appropriate accessories (GPC series precision grinding and polishing controller), high-quality surface grinding and polishing products can be mass-produced, such as the grinding and polishing of wafer samples with a diameter of ≤Ø160mm. The sample can be ground by grinding disc plus abrasive, or by polishing disc with sandpaper. The sandpaper or polishing pad is clamped by magnetic adsorption, which is convenient for loading and unloading. The specific choice of sandpaper grinding or abrasive grinding can be selected according to the material of the sample to be ground.

Main features of laboratory grinding polishing machine:

1. High-precision rotating chuck.

2. The spindle and the rotating disk are coaxial with high precision.

3. The spindle can be automatically raised and lowered, which is convenient for multi-size grinding and polishing; the spindle can be infinitely adjusted in speed.

4. The laboratory polishing machine for metal is equipped with a timed polishing function, making polishing smarter.

5. The laboratory polishing machine for metal can be equipped with an automatic dripper, which makes grinding and polishing more convenient.

Technical parameters of laboratory precision polishing machine:

Product Name | UNIPOL-2001 Precision Grinding and Polishing Machine / Lapping Machine |

Product Model | UNIPOL-2001 |

Main Parameters (Specification) | 1. Grinding disc: diameter φ508mm (20 inches) (grinding disc is not included in the standard configuration, please consult sales for specific materials) 2. Sample plate: diameter φ160mm (6 inches), thickness 35mm. 3. Repair ring: outer diameter φ196mm, inner diameter φ160.5mm, thickness 35mm. 4. Swing arm bracket: 1 set every 120°, a total of 3. 5. Number of workstations: 3. 6. Grinding disc speed: number of revolutions: 20-120 rpm. 7. Bracket swing speed gear: 15-30 gears (reference speed: 5.5-13.5 times/minute). 8. Transmission mechanism motor: variable frequency motor: 1.5kW, 220V. 9. Total power: 1.7kW 220V. |

Product Dimension | Dimensions: Size: Floor-standing, 820*1180*945mm. Weight: 450kg.

|

Optional accessories:

| No. | Name | Function category | Picture |

| 1 | SKZD-2 Dripper | (optional) |  |

| 2 | SKZD-3 Dripper | (optional) |  |

| 3 | φ508mm Cast Iron Grinding Disc | (optional) |  |

| 4 | φ508mm Cast Aluminum Disc | (optional) |  |

| 5 | φ508mm glass disc | (optional) | -- |

| 6 | φ508mm Polishing Pad | (optional) |  |

| 7 | Wax-Free Polishing Disc (size: can be customized according to customer requirements) | (optional) |  |

Warranty:

One year limited with lifetime support (not including rusted parts due to inadequate storage conditions).

Logistics:

About us:

Shenyang Kejing is committed to providing scientific research services to universities, scientific research institutes, and manufacturing enterprises. Its products are positioned in the scientific research market and mainly serve universities, scientific research institutions, and laboratories. Our products have comprehensive after-sales service guarantees and professional transportation capabilities to ensure timely delivery of products.