News

The UNIPOL-300 small precision grinding and polishing machine launched by Shenyang Kejing has quickly become an ideal choice for metallographic laboratories and electron microscopy laboratories with its excellent precision and intelligent operation. Next, please come with me to see the excellent performance of small precision grinding and polishing machine in production!

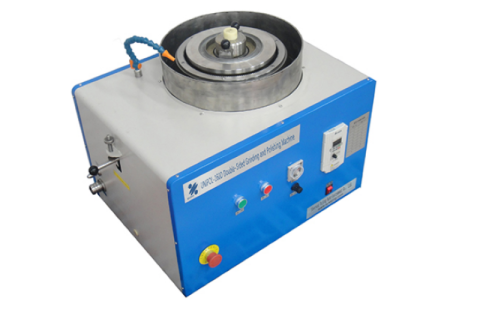

With the long-term use of UNIPOL-160D double-sided lapping and polishing machine, some common faults may affect production efficiency and processing quality. Therefore, understanding the causes and solutions of these faults can help you effectively extend the service life of dual face lapping and polishing machines and ensure the stability of production.

In this golden autumn season,Shenyang Kejing Auto-instrument Co., Ltd. successfully held an employee family open day on September 15, 2024. The event specially invited company employees and their families, a total of more than 90 people participated, to spend a warm Mid-Autumn Festival together.

On September 11, 2024, the 25th CIOE China Optoelectronics Expo opened grandly at the Shenzhen International Convention and Exhibition Center, attracting more than 3,700 high-quality optoelectronic companies from around the world. As an important event in the optoelectronics industry, CIOE China Optoelectronics Expo showcases the latest technological achievements in multiple fields including information communication, precision optics, lasers and intelligent manufacturing. Our company brought a number of leading optoelectronic products and technologies to the exhibition, attracting widespread attention and praise.

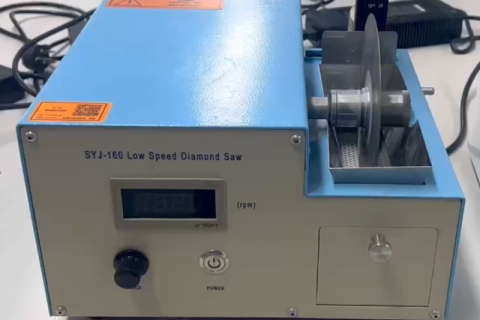

Small water pump is specially designed for laboratories and enterprises. After careful selection, the water pump is suitable for our STX series diamond wire cutting machine, SYJ series external cylindrical cutting machine, and all other equipment that can be cooled by circulating liquid, becoming an indispensable auxiliary equipment in laboratories and production environments.

Vacuum chucks are an important tool used in the industrial field. The formulation and compliance of operating procedures are essential to ensure work safety and improve work efficiency. Similarly, the maintenance and care of equipment are also very critical.

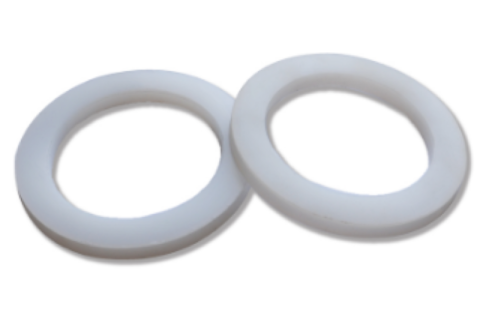

In the cutting production process, the guide roller wheel, as a key component, plays a vital role in the accuracy and efficiency of cutting. The guide wheel is made of plastic material to meet diverse cutting needs. Among them, the unique performance characteristics of the guide roller wheel have been widely used in specific application scenarios.