New Guide Wheel Improves Diamond Wire Saw Performance

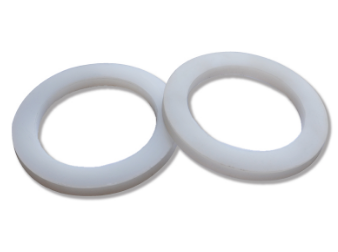

2024-09-12 15:30In the cutting production process, the guide roller wheel, as a key component, plays a vital role in the accuracy and efficiency of cutting. The guide wheel is made of plastic material to meet diverse cutting needs. Among them, the unique performance characteristics of the guide roller wheel have been widely used in specific application scenarios.

The guide roller wheel produced by shenyang kejing is suitable for stx series diamond wire cutting machines. Its main function is to guide the diamond wire when cutting samples, so that the diamond wire moves in a fixed direction, and cooperates with the tensioning wheel to complete guidance and tensioning. Function and complete the entire cutting process. The guide roller wheel is designed to increase cutting efficiency and precision while ensuring operational safety.

The bearing roller guide wheels we provide are lightweight, which can reduce the overall load of the equipment and help improve the efficiency of the equipment. The plastic guide wheels have excellent corrosion resistance and are not easily affected by chemicals, moisture or oxidation, making them suitable for use in harsh environments. The bearing roller guide wheels have a low friction coefficient when in contact with other parts during operation, which can reduce friction loss, thereby extending the service life and improving operation stability and reducing maintenance costs. High-performance guide wheels have good wear resistance and can maintain their shape and function for a long time.

When using bearing roller guide wheels, it is necessary to avoid overloading to avoid damage or poor shock absorption. Regularly check the appearance of the guide roller wheel for wear and replace damaged parts in time. These precautions ensure the stability and service life of the guide wheel, while ensuring the stability and processing accuracy of the machine, reducing noise and impact on the surrounding environment.

Our company's product line also includes other material preparation and analysis equipment, such as grinding and polishing machines, cleaning machines, film making equipment, etc., designed to meet the full set of preparation and analysis needs of crystals, ceramics, glass, petrographic phases, mineral samples, metal materials, refractory materials, and composite materials. At the same time, our products are also exported to the united states, japan, europe and other countries and regions. If you need it, please contact us in time, we will ship it to you as soon as possible!

Okay! This is the end of this news, I hope the article can help you!