News

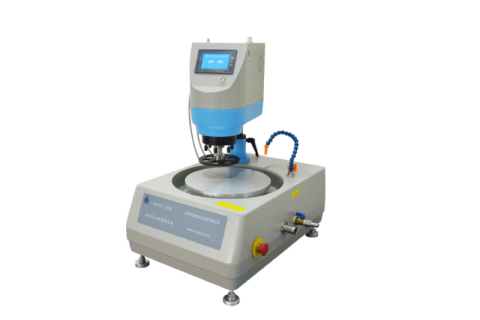

In modern industry and scientific research, the demand for precision processing of materials is becoming more and more stringent. Whether in the steel manufacturing industry or in the high-tech field, the surface quality and grinding accuracy requirements for artificial crystals, ceramics and infrared optical materials (such as zinc selenide, zinc sulfide, silicon and germanium, etc.) have reached new heights. UNIPOL-1260A Vacuum and heating grinding and polishing machine is designed for such high-precision processing needs. It is widely used in the grinding and polishing of hard and brittle materials such as quartz glass, rock, white gemstone and sapphire, meeting the diverse application needs from laboratories to large-scale production workshops.

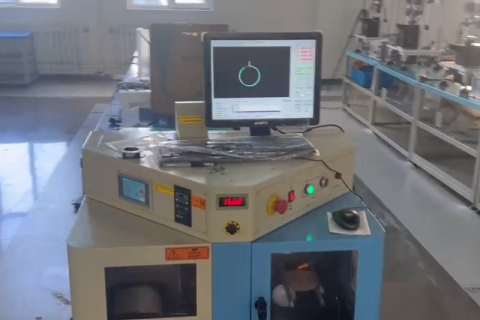

UNIPOL-1260 Stepless variable speed pressure regulating polishing machine has become the preferred equipment for steel plants and metallographic sample preparation due to its precise and efficient grinding capabilities. Whether it is artificial crystals, ceramics or infrared optical materials, stepless variable speed pressure regulating polishing machine can achieve high-precision processing, shortening sample preparation time while improving sample preparation quality. Next, please appreciate its performance with me!

In modern manufacturing, UNIPOL-1200M automatic pressure grinding and polishing machine is a key equipment and is widely used in many industries such as metal, ceramics, glass and composite materials. The unique surface treatment ability of desktop grinding and polishing machine not only improves the appearance quality of the product, but also significantly improves the mechanical properties and processing accuracy of the material. Let's take a look at how desktop grinding and polishing machine is used in different fields!

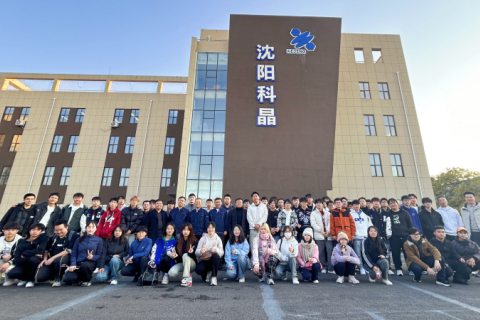

On the afternoon of October 23, 2024, teachers and students of the Applied Physics Department of the School of Science of Shenyang University of Technology visited Shenyang Kejing Auto-instrument Co., Ltd. and carried out a unique production internship and study activity. Shenyang Kejing's senior leaders and reception team warmly welcomed the visiting study team at the entrance of the company.

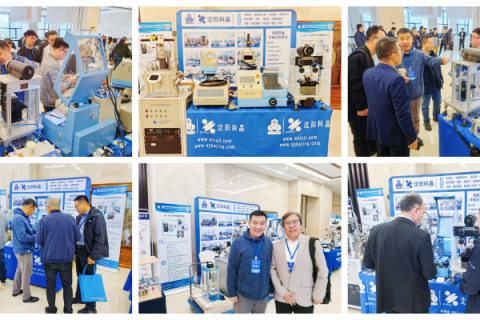

In order to promote the innovative development of green low-carbon metallurgy, intelligent metallurgy, high-end metal manufacturing and resource recycling, it is jointly guided by the expert groups of China Metal Society, China Nonferrous Metals Society, Liaoning Province and Shenyang Science and Technology Association, and hosted by Northeastern University The "2024 International Academic Conference on Metallurgical Innovation and Development" was successfully held in Shenyang from October 17th to 19th. With the theme of "Green, Intelligent, High-end, and Circular", this conference brings together cutting-edge technologies and innovations in the metallurgical industry. During the conference, nearly 130 experts and scholars in six sub-venues conducted in-depth discussions on hotspots and difficulties in the fields of green low-carbon metallurgy, metallurgical digitalization, intelligence, high-end metal material manufacturing, resource recycling and new energy metallurgical applications.

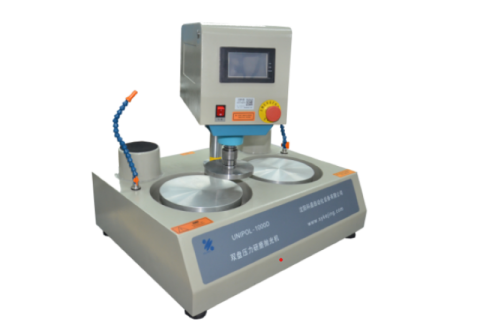

In the field of materials research, UNIPOL-1000D double disc pressure grinding and polishing machine has become an indispensable equipment in laboratories of major universities, research institutes and small-scale production in factories with its high efficiency and wide applicability. With its double-station design, the double disc grinding and polishing machine not only effectively avoids cross contamination between grinding and polishing, but also significantly improves work efficiency.

Recently, Shenyang Kejing Auto-instrument Co., Ltd. held a conference with the theme of "Learning and Exchange" to promote knowledge sharing and technical exchanges among employees and further enhance the company's professional level in the industry. The meeting attracted the participation of managers and technical teams from various departments of the company.

In the production and processing process, the normal operation of the UNIPOL-800m multi-point mechanical pressure grinding and polishing machine is crucial to ensure the quality of the workpiece. However, in daily use, various problems may occur, affecting the processing effect of the workpiece. This article summarizes several common faults of automatic pressure grinding and polishing machine and the corresponding solutions to help manufacturers maintain equipment in a timely manner and improve production efficiency.