News

In order to improve the automation level of laboratory sample preparation, Shenyang Kejing Automation Instrument Co., Ltd. has developed an intelligent grinding and polishing equipment that integrates a collaborative robot and a multi-functional operating platform to achieve efficient, precise and automated operations. The following is the detailed usage process of robotic grinding and polishing workstation:

Compared with the previous one, this peach shaped hole workpiece fixing tool has been upgraded. This sample tray has three stations and is designed for UNIPOL series precision grinding and polishing machines. It can provide more efficient and stable grinding and polishing effects. First of all, let's understand what is the "outstanding feature" of this product?

In order to enrich the cultural life of employees and enhance team cohesion, Shenyang Kejing successfully held the "2024 Employee Fun Sports Meeting". With the theme of winter enthusiasm, this sports meeting set up five interesting events: tug of war, double rope skipping, table tennis, hooping, and darts. It attracted the active participation of the company's employees and injected infinite vitality and laughter into the cold winter.

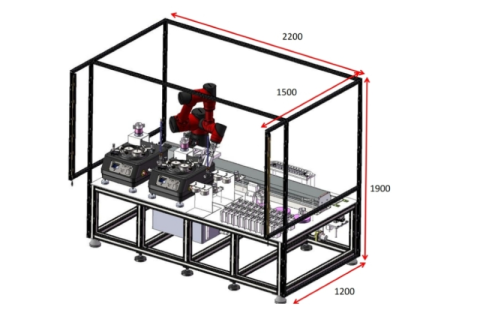

Shenyang Kejing recently launched a new equipment: "UNIPOL-1220S automatic grinding workstation", which brings a new user experience to users with its fully automated and intelligent design and optimization of functions and operations. Next let us learn about it together!

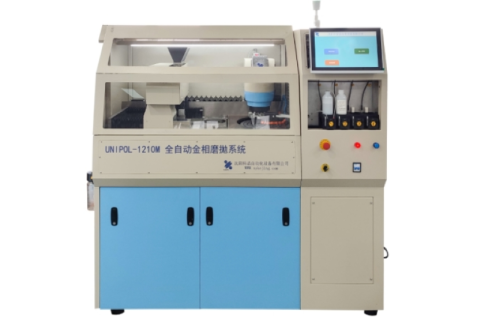

In materials science research, the efficiency and accuracy of the metallographic sample preparation process directly affect the reliability of experimental results. In order to meet the needs of scientific research institutions and industrial laboratories for automation, precision and consistency, we have developed a device called "UNIPOL-1210M fully automatic metallographic grinding and polishing system", which not only provides a highly integrated sample preparation solution, but also can cover a series of full-process automated operations such as mounting, grinding, polishing and cleaning. Let's take a look at how the automatic grinding and polishing machine performs at work!

Recently, we have launched a new product: Tem wedge grinding and polishing fixture. It can be mainly used in semiconductor materials (section, plane), ceramic materials, metal materials, composite materials, etc. To shorten the thinning time. Our product has three major technical highlights. You all know it. Let us take a look at it together!

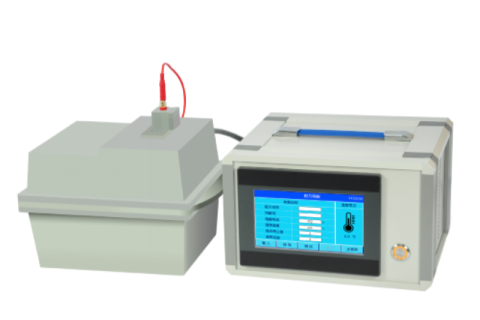

In the precise world of scientific research, transmission electron microscope sample preparation is a crucial link. The intelligent and visual technical advantages of TJ100-SE automatic twin jet electropolisher provide an efficient and stable sample preparation method for thinning metal electron microscope samples.

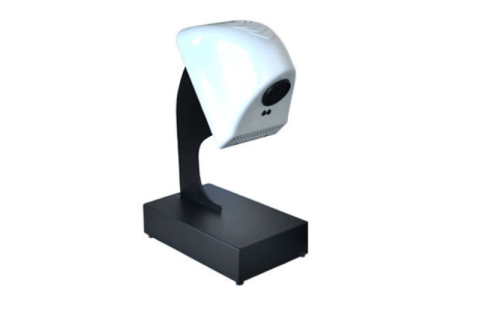

In the daily work of the materials laboratory, the rapid drying of samples and the hygienic cleaning of hands are often the focus of researchers. And a drying device that is both efficient, hygienic and convenient is quietly becoming the "new favorite" of the laboratory. Laboratory induction automatic dryer, this intelligent device tailored for the materials laboratory, is redefining the standard of laboratory drying tools with its excellent design and performance.

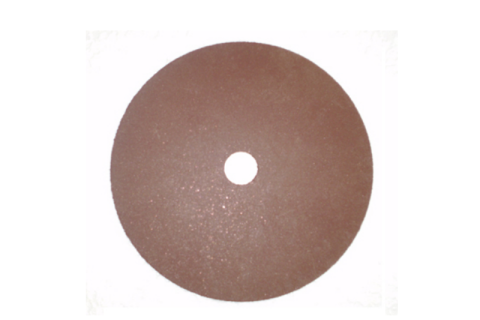

1. Cutting speed of electroplated diamond saw blade: Electroplated diamond saw blade is made of diamond particles electroplated on a metal matrix. It has high hardness and wear resistance and is suitable for cutting stone, building materials and other fields. Its cutting speed is affected by many factors, such as cutting materials, saw blade size, rotation speed, etc.

In metal cutting, it is very important to choose the right saw blade material. Different metal types, hardness and cutting conditions require different saw blade materials to ensure cutting efficiency and tool life. Therefore, how to choose the most suitable metal cutting saw blade material has become a key issue in the processing industry. This article will analyze several common metal cutting saw blade materials in detail, with special emphasis on materials suitable for high hardness and high precision requirements, to help you make a wiser choice.