Robotic Grinding and Polishing Workstation Operation Process Full Steps

2025-02-10 15:30In order to improve the automation level of laboratory sample preparation, Shenyang Kejing Automation Instrument Co., Ltd. has developed an intelligent grinding and polishing equipment that integrates a collaborative robot and a multi-functional operating platform to achieve efficient, precise and automated operations. The following is the detailed usage process of robotic grinding and polishing workstation:

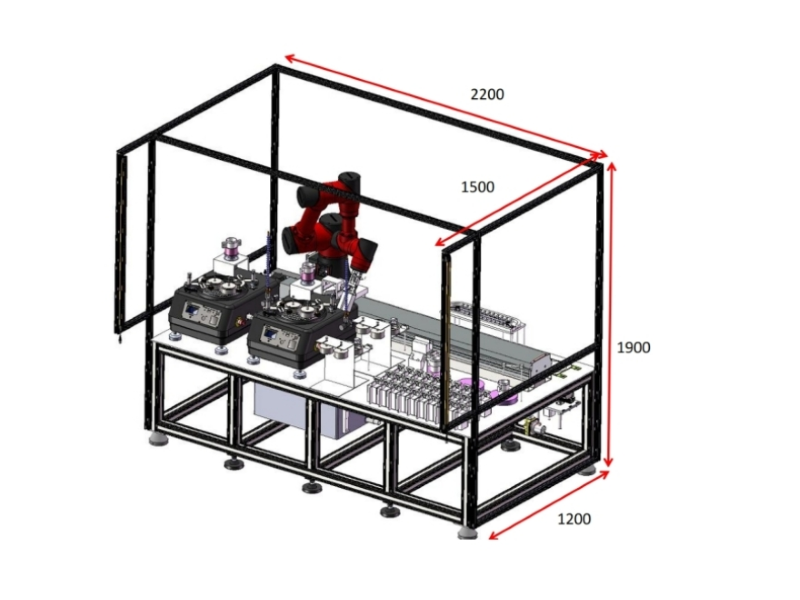

The composition of robotic grinding and polishing workstation:

1. Collaborative robots and sliding tables: responsible for automatically grabbing, transporting, and placing samples and consumables.

2. Grinding and polishing area: Equipped with high-precision grinding and polishing equipment for sample surface treatment.

3. Sample storage area: place dressing discs, sample loading discs, and abrasive discs in categories.

4. Automatic liquid adding system: Automatically adds grinding and polishing liquid and water to maintain the best grinding state.

5. Waste liquid treatment area: centrally process and collect grinding and polishing waste liquid to keep the work surface clean.

Operating procedures of robotic grinding and polishing workstation:

1. Grab the dressing ring:

The robot first grabs the dressing disc ring from the dressing disc storage area and places it into the grinding and polishing equipment to ensure that the grinding disc surface is smooth.

2. Grab the sample tray:

The robot accurately grabs the sample tray on which the sample has been placed and transports it to the top of the grinding and polishing equipment.

3. Place the sample tray:

Accurately place the sample plate on the workbench of the grinding and polishing equipment to prepare for the next step of grinding and polishing.

4. Grab the abrasive box:

The robot automatically grabs the abrasive box containing abrasives and prepares to load grinding and polishing materials.

5. Place the abrasive box and weigh it:

Place the abrasive box in the weighing area and automatically detect the amount of abrasive used to ensure accurate supply of abrasive materials.

6. Confirm that the abrasive excess weight is sufficient:

The system automatically detects whether the abrasive is sufficient, and the overweight portion will be automatically adjusted.

7. Put the abrasive box into the quantitative feeder:

Accurately place the abrasive box into the quantitative feeder to achieve automated and precise abrasive supply.

Shenyang Kejing's robotic grinding and polishing workstation not only greatly improves the efficiency and accuracy of sample preparation, but also effectively reduces errors and safety hazards caused by manual operations. In the future, we will continue to adhere to the concept of "technological innovation, quality first" to provide more intelligent, efficient and reliable material preparation equipment for global users. Customers are welcome to visit, consult and cooperate to create a new technological future!