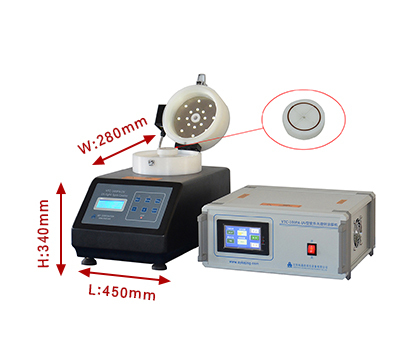

Hi-Speed Spin Coater (10K rpm & 5" Max) With UV Cover

VTC-100PA-UV UV Spin Coater is suitable for semiconductor process, crystal, optical disc, plate making and surface coating, etc. The upper cover adopts UV light source and is especially suitable for materials sensitive to UV light, which can quickly solidify the coated film. In addition, the UV lamp also has a polymerization function, which can polymerize the monomer into a polymer film.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Main Features

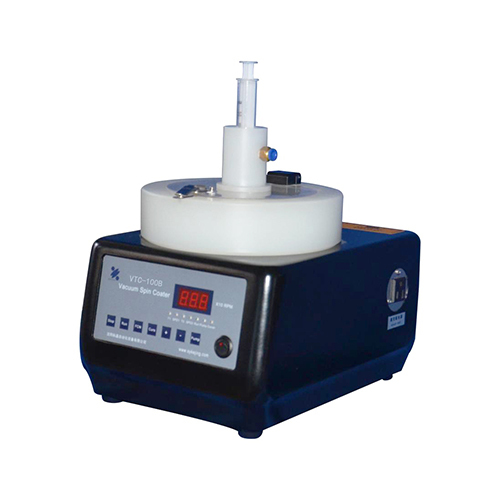

1.The sample is fixed by means of vacuum adsorption, which is easy to operate and convenient to take and place samples, which can be customized as required.

2. The upper cover adopts UV light source, whose strength can be adjusted within a certain range.

3. The injection hole is located in the center of upper cover and is equipped with a rubber plug, which is applied when sealed environment is required for the chamber.

4. The gas inlet hole in the chamber is used to connect to protective gas.

5. The motor part and the UV light control part are independently controlled. The motor speed regulation system is controlled by a single-board computer plus a LCD screen, the numerical display is more intuitive and reliable. The UV light is controlled by a PLC controller with strong anti-interference.

6. The coating speed of this machine is 500 to 1000RPM. 12 groups of programs can be stored, each group of programs contains 6 operating stages, and the operating parameters of each stage can be set independently to make the speed slowly increase to the limit, which is conducive to form uniform film on the sample surface, and will not waste too much.

7. The UV vacuum spin coater starts quickly and has a stable rotation speed, which can ensure the uniformity and consistency of film thickness.

8. In the installation structure, shock absorption measures are taken to reduce noise during operation.

9. The chamber is made of PP material with longer service life to improve the resistance abilities of chemical corrosion and excellent stress crack, and the machine body adopts cast aluminum structure, which is durable and light in weight.

Technical Parameters

Product Name | VTC-100PA-UV UV Spin Coater |

Product Model | VTC-100PA-UV |

Installation conditions | 1. Temperature and humidity: 10-85%RH (at 25℃ without condensation) Temperature: 0-45℃. 2. There is no strong vibration source and corrosive gas around the equipment. 3. Water: No need. 4. Electricity: Single phase: AC220V 50Hz National standard three-pole socket 10A must be well grounded. 5. Gas: Vacuum negative pressure (vacuum pump) The air flow rate is not less than 70L/M (the equipment can pass protective inert gas). 6. Workbench: It is recommended to be 800X600X700mm and bear a load of more than 50KG (solid cement platform is better). 7. Ventilation device: No special requirements. |

| The main parameters | 1. Power supply interface: Power socket with insurance: AC220V 50Hz, insurance tube specification is 10A, φ5×20mm (this device supports AC110V 50/60Hz product customization). 2. Total power: ≤180W (excluding external vacuum pump). 3. Coating host cavity (material): polypropylene. 4. Sample tray (suction cup): polypropylene suction cup Φ19mm, Φ60mm each. 5. Operation mode: 12 sets of programs can be stored, each set of programs contains 6 operation stages. 6. Coating speed: 500rpm-10000rpm is effective. 7. Acceleration and deceleration rate: The setting range of each acceleration and deceleration rate is 100 rpm —2000 rpm. 8. Coating time: Each time range: 0-60s. 9. Speed stability: ±1%. 10. Host control mode: PCB single-chip microcomputer key control LMC LCD display. 11. Curing method: 16 LED purple light beads. 12. Curing time: purple light time setting range: 1-800s. 13. Curing power: purple light power range: 5-30W adjustable. 14. Curing control method: touch screen (independent control of purple light system, not related to host control). |

| Product Specifications | Dimensions: 450×280×340mm Weight: 18Kg

|

Standard accessories

| Serial number | Name | Quantity | Image link |

| 1 | Vacuum suction cup (with O-ring) (Ø19mm and Ø60mm) | 2 |   |

| 2 | Center locator | 1 |  |

| 3 | Oil-free vacuum pump | 1 |  |

Optional accessories

| Optional accessories | Name | Functional category | Image link |

| 1 | Other sizes of vacuum cups | (Optional) |  |

| 2 | Domestic pipette gun | (Optional) |  |

| 3 | Imported pipette | (Optional) |  |

Warranty

One year limited with lifetime support (not including rusted parts due to inadequate storage conditions)

Logistics