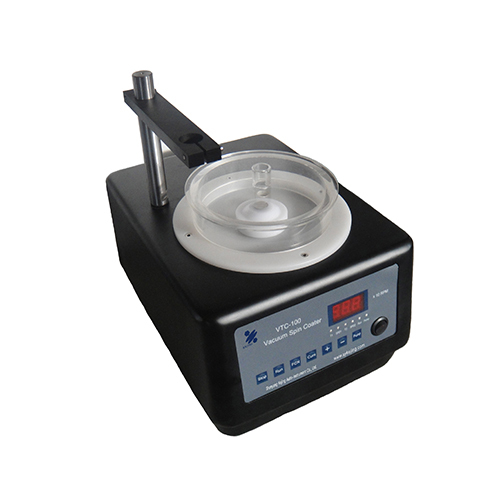

Spin Coater (8K rpm, 4" Wafer Max.) With 3 Vacuum Chuck

VTC-100 Vacuum Spin Coater is equipped with 3 vacuum chucks (for standard) of different sizes, and different vacuum chucks can be selected according to the size of samples. During working, VTC-100 vacuum spin coater uses vacuum plate adsorption method to fix the sample onto the sample plate. The equipment uses two-stage program to control the speed.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Main Features

1. The speed is controlled by a two-stage program:the glue is injected in the first low-speed stage, and the glue is leveled in the second high-speed stage.

2. The sample is fixed by vacuum adsorption, which is easy to operate and convenient to take and place the sample.

3. Cast aluminum structure, stable operation and low noise

4. The power supplies for motor and for controller are supplied independently.

5. The speed regulation is controlled by a single chip computer with high anti-interference, and the speed is very stable within the range of 1000 to 8000RPM.

6. LED digital display, with spin coating countdown display function

7. The oilless parallel-bar vacuum pump has the advantages of small size, simple structure, easy operation, convenient maintenance, and no environmental pollution.

Technical Parameters

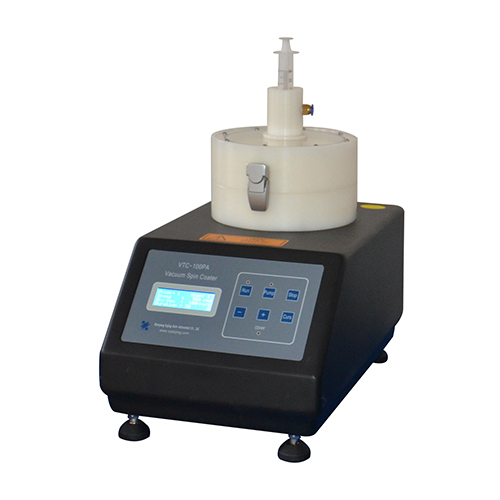

Product Name | VTC-100 Vacuum Spin Coater |

Product Model | VTC-100 |

Installation Conditions | 1. Temperature and humidity: 10-85%RH (at 25℃ without condensation) Temperature: 0-45℃. 2. There is no strong vibration source and corrosive gas around the equipment. 3. Water is not required 4. Electricity: Single phase: AC220V 50Hz National standard three-pole socket 10A must be well grounded 5. Gas: Vacuum negative pressure (vacuum pump) exhaust flow rate is not less than 70L/M 6. Workbench: 800X600X700mm recommended bearing weight of more than 100KG (solid cement platform is better) 7. Ventilation device: no special requirements |

The main parameters | 1. Power supply interface: Power socket with insurance: AC220/110V 50/60Hz, insurance tube specification is 10A, φ5×20mm 2. Total power: ≤150W 3. Sample tray (suction cup): Polypropylene vacuum suction cup Φ25mm φ50mm φ100mm, one each 4. Operation mode: Counterclockwise rotation, with two operation stages 5. Coating speed: SPD1 speed: 500-8000 RPM effective SPD2 speed: 500-8000 RPM effective 6. Coating time: T1 time: 1--600s effective T2 time: 1--600s effective 7. Speed stability: ±1% 8. Control mode: PCB single chip microcomputer, button control, digital tube display Note: In order to avoid damage to the equipment caused by misoperation/mistouch during use by customers, the "voltage conversion switch" at the rear of the domestic standard equipment only supports AC220V 50Hz Power supply: If you need AC220V/AC110V 50HZ/60Hz conversion equipment, please communicate with our sales staff. The actual power supply of the equipment shall be based on the label attached to the back of the product. |

Product Dimension and Weight | Dimension: 380mm×260mm×330mm weight: 12kg

|

Standard Accessories

No. | name | qty | picture |

1 | Vacuum Chuck (PP, Ø25mm, Ø50mm, Ø100mm) | 1 pcs each | |

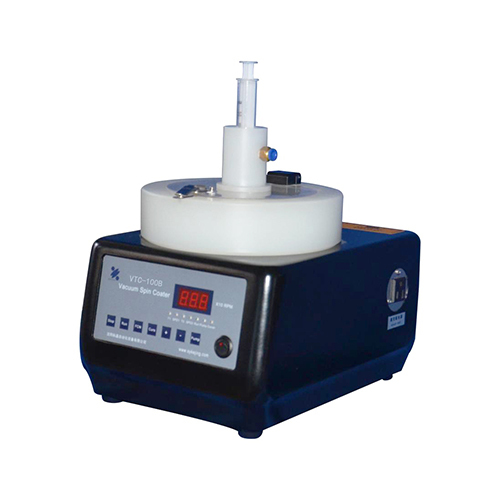

2 | Injector/Syringe | 1 pcs | |

3 | Oilless Vacuum Pump | 1 pcs |  |

Optional Accessories

No. | name | functional type | picture |

1 | Special Vacuum Chuck (PTFE, aluminum alloy) | (optional) | - |

2 | Micro-Size Chuck | (optional) | |

3 | Filter (for vacuum pump) | (optional) | - |

4 | Pipette (made in China) | (optional) | |

5 | Pipette (imported) | (optional) | |

6 | Sample Clamping Plate | (optional) |

|

Warranty

One year limited with lifetime support (not including rusted parts due to inadequate storage conditions)

Logistics