6 Position Programmable Dip Coater With Bottom Heating

PTL-6PB Six-Position Dip Coater is equipped with six temperature-controlled meter, which can heat the charging beaker during film coating process. The six beakers can be heated with the same temperature or different temperatures, depending on the coating materials loaded in the beakers. This machine is suitable for liquid coating materials or solid coating materials that can be melted into flowing liquid after heating.

- Shenyang Kejing

- Shenyang, China

- 22 working days

- 50 sets

- Information

Product Introduction

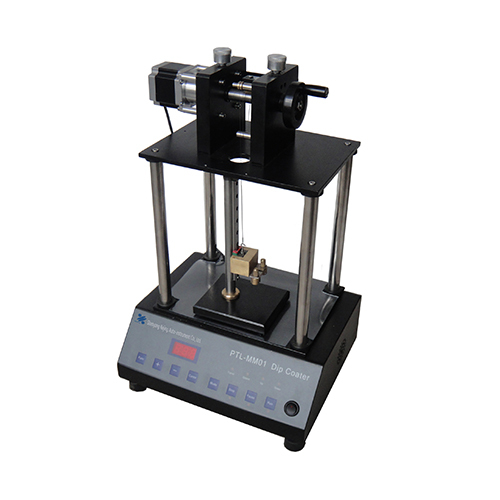

The PTL-6PB Six-Station Dip Coater can lift one sample at a time. Through program control, the sample rotates counterclockwise, immerses in the solution cup for a set period, and is then pulled out for drying. Both immersion time and drying time can be programmed.

The six solution cups of the PTL-6PB can either contain the same coating material or be filled with different coating materials. The unit is equipped with six temperature controllers, allowing heating of the solution cups during the coating process. Each cup can be heated to the same temperature or to different temperatures, depending on the coating materials used.

This machine is suitable for liquid film materials or solid film materials that become flowable liquids after heating. With its compact size, space-saving design, simple operation, suitability for beginners, and ease of cleaning, the PTL-6PB Six-Station Dip Coater is widely used in laboratories of universities, research institutes, and enterprises.

Main Features

1. There are 6 workstations/positions, and the samples can be rotated counterclockwise.

2. Program-controlled pulling speed, dipping time and drying time, etc.

3. A high-precision stepper motor is adopted.

4. CE certified.

Technical Parameters

Product Name | PTL-6PB Six-Position Dip Coater | |

Product Model | PTL-6PB | |

Installation Conditions | This equipment is required to be used at an altitude of 1000m or less, a temperature of 25℃±15℃, and a humidity of 55%Rh±10%Rh. 1. Water: N/A 2. Electricity: AC220V 50Hz, must have good grounding 3. gas: N/A 4. Workbench: size 500mm×800mm×700mm, bearing more than 50kg 5. Ventilation device: no need | |

Main Parameters (Specification) | 1. Power supply: 220V 1200W 2. Stirring speed: 1-5rpm (whether each station/position needs stirring or not, it can be set separately. ) 3. pulling speed: automatic ascending and descending speed: 1-400mm/min, manual ascending and descending speed: 1-150mm/min 4. pulling times: 1-45 times 5. Dipping and drying time setting: 1-999s 6. Travel distance setting: 1-80mm (adjustable) 7. beaker: 150ml 8. Sample size: 75mm×25mm×2mm 9. Effective dipping length: 60mm 10. Heating temperature: RT-80℃, the heating temperature of each station/position can be set separately. | |

Product Dimension and Weight | Dimension: 260mm×340mm×420mm Weight: 15kg |

|

Standard Accessories

| No. | Name | Quantity | Image |

| 1 | Sample Clamp (single piece) | 1 pcs | - |

| 2 | Beakers | 6 pcs | - |

Optional Accessories

| No. | Name | Function Category | Image |

| 1 | Sample Clamps (double piece) | Optional | - |

| 2 | other Clamps | Optional | - |

Warranty

One year limited with lifetime support (not including rusted parts due to inadequate storage conditions)

Logistics