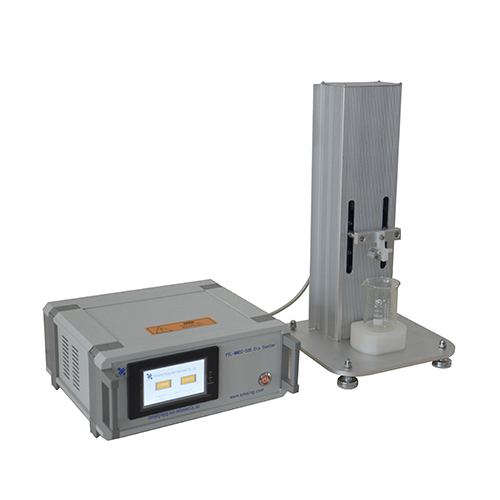

Millimeter Grade Programmable Dip Coater (1-200 mm/min)

PTL-MM02 Program-controlled dip coater pulls the sample vertically by pulling the wire. PTL-MM02 programmable dip coater adopts PLC program control to set and adjust the the pulling speed, the dipping time of the sample in the liquid coating material, the speed of the sample entering the liquid, the cycle times of the sample entering and leaving the liquid coating material as well as the drying time of the sample.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Introduction of dip coating:

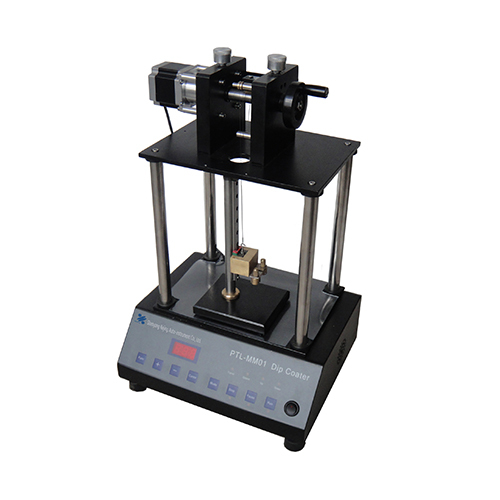

PTL-MM02 programmable control film coating machine is a CE certified product. Dip coating is a millimeter-level precision film coating equipment designed by our company for liquid phase immersion film coating experiments. It is a necessary product equipment for liquid phase film growth research units and institutes. Dip coating adopts PLC program control system to control high-precision stepper motor with control actuator and pulling wire to do lifting and pulling operation. The lifting process is stable and accurate; by vertically immersing and pulling the sample, the sample is immersed in the liquid phase film material for a period of time and then pulled out, so that a certain thickness of film grows on the surface of the sample. Dip coating can choose two program operation modes: "single-pass operation" and "full-pass operation". The program can independently set the sample lifting speed, the descending liquid entry speed, the sample immersion residence time in the liquid phase film material, the sample drying time, and the number of cycles of the sample entering and exiting the liquid phase film material. This series of program-controlled dip coating machines are divided into two models: PTL-MM02 normal temperature type (i.e. room temperature) and PTL-MMB02 constant temperature type with constant temperature heating drying oven. You can choose the appropriate model according to the process temperature requirements of the dip coating growth. The dip coating model is small in size, simple to operate and easy to carry, and is widely used in laboratories of colleges, research institutes and corporate units.

Advantages of dip coating:

1.Dip coating is equipped with a 4.3-inch color touch screen, and the control interface is simple and clear, which is suitable for beginners.

2.Dip coating is small in size, cost-effective, and saves laboratory operation space.

3.Dip coating uses PLC program to control high-precision stepper motor drive, and suspended wire conduction pulling technology to reduce shock.

Technical parameters of film coating:

Product Name | PTL-MM02 Programmable Dip Coater |

Product Model | PTL-MM02 |

Installation Conditions | 1. Power supply: AC220V 50/60Hz national standard 10A socket, must be well grounded; 2. Site environment: Use at a temperature of 25℃±15℃ and a humidity of 55%Rh±10%Rh. |

Main Parameters (Specification) | 1. Working voltage of the lifting machine: DC24V 3.75A (standard: AC100~240V power adapter). 2. Power of the lifting machine: 50W. 3. Type: program control-normal temperature type. 4. Drive motor: high-precision stepper motor. 5. Speed setting range: 1-200mm/min. 6. Dwell time: 1-999s. 7. Drying time: 1-999s. 8. Lifting stroke: 1-75mm. 9. Number of pulls: 1-20 times. 10. Effective immersion length: 60mm. 11. Upper limit of lifting load: <100g. 12. Sample substrate size: 75mm×25mm×2.5mm. 13. Display control: 4.3-inch color touch screen. |

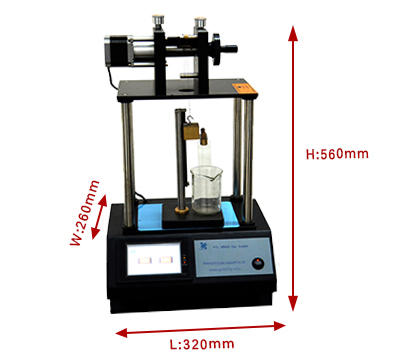

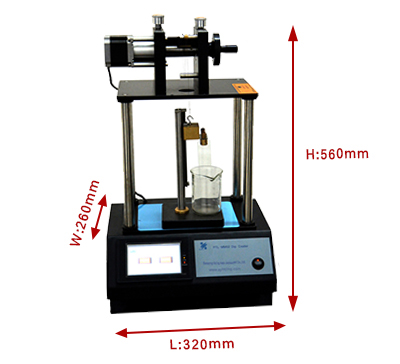

14. Product specifications: Size: 320mm×260mm×560mm; Weight: ≈17kg.

| |

Note: 1. Specifications of the standard "power adapter": IN: AC100-240V 50/60Hz OUT: DC-24V 3.75A. The actual power supply of the device is subject to the label attached to the back of the product; 2. Customizable AC110V 50/60Hz constant temperature oven; | |

Standard accessories of film coating:

| NO. | Name | Qty | Image Link |

| 1 | Sample fixture | 1 set | -- |

| 2 | Loading cup | 1 pcs | -- |

| 3 | Raising wire | 3 items | -- |

Warranty:

One year limited with lifetime support (not including rusted parts due to inadequate storage conditions)

Logistics:

About us:

We have advanced production equipment and strict quality management system, so that every product meets international standards. Our R & D team continues to innovate and is committed to improving product design based on market demand and customer feedback to provide more accurate and efficient solutions. With years of industry experience and technical accumulation, we have established a good reputation in the industry and won favorable comments from many customers.