- Home

- >

News

Our company continues to deepen its efforts in the direction of equipment automation and intelligence, and insists on independent research and development. Through our countless experiments and improvements, the precision diamond wire saw gradually took shape. In order to ensure its cutting accuracy, the team spent a lot of effort on the selection of diamond wire. They tested dozens of different diamond materials and processes, and finally selected the most suitable one. This diamond wire not only has ultra-high hardness and wear resistance, but also can remain stable under high temperature and high pressure environments, providing a solid guarantee for precision cutting. In order to improve the user experience, the team also put a lot of effort into the human-computer interaction interface of the equipment. By introducing advanced control systems and friendly operation interfaces, users can complete complex cutting tasks in just a few steps.

In modern industry and construction, the advancement of cutting technology provides strong support for efficient and safe operations. Among them, Diamond Wire Saw with Protective Cover has become a cutting-edge technology that has attracted much attention in the industry due to its excellent performance and diverse application scenarios.

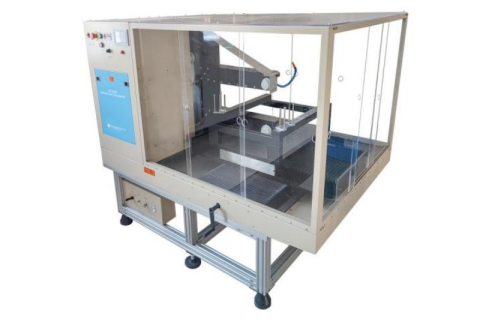

In today's industrial environment that pursues efficiency and environmental protection, Diamond Wire Saw For Cutting Various Shapes Max. 400mm Square has become a leader in the industry with its green cutting technology and safe design. The dust generated by the Diamond Wire Saw during the cutting process is effectively controlled in the protective cover to prevent dust leakage. This reduces air pollution and protects the health of operators. The protective cover design is also equipped with a dust collection system to further reduce dust emissions.

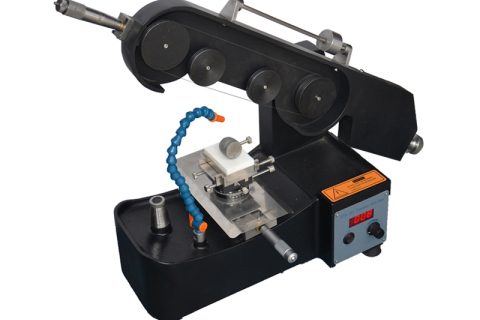

Pneumatic Tension Diamond Saw is a representative of high-precision and high-efficiency cutting tools. In order to ensure the long-term stable operation and optimal performance of the equipment, regular care and maintenance are essential.

As an innovative tool of modern cutting technology, Diamond Wire Cutting Saw occupies an important position in industry and scientific research with its excellent cutting ability and wide application fields.

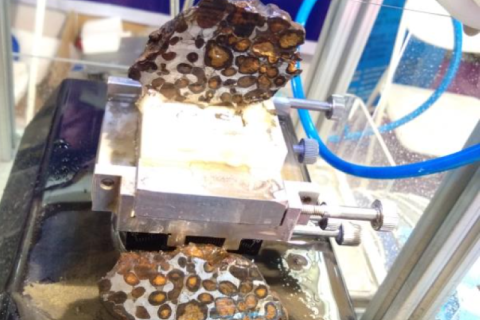

Endless Diamond Wire Saw is designed for fragile, brittle and small-volume materials. Its high precision and versatility set new standards in the processing of various precision materials and have attracted widespread attention from scientific research institutions and high-end manufacturing industries.

At present, as early as 2016, the global monocrystalline silicon wafer producers have basically switched all traditional mortar cutting (silicon carbide powder, steel wire, polyvinyl alcohol mixture) to diamond wire saw, which has greatly reduced the cost of monocrystalline silicon wafers, resulting in a certain cost-effectiveness advantage in the competition with multicrystalline silicon wafers. Therefore, multicrystalline silicon wafers must all switch to diamond wire slicing as soon as possible. Multicrystalline silicon wafer companies that do not switch will face the dilemma of being unable to survive.

From March 29 to 31, the first Applied Physics Conference and the National Applied Physics Education Development and Reform Forum was opened in the Yangtze River Delta Physics Research Center, Liyang High-tech Zone. More than 600 well-known experts, scholars and entrepreneurs in the industry participated in the conference, which aims to provide an open, high-quality and efficient academic exchange platform for researchers in applied physics and related fields, promote cross-border cooperation and exchange between various fields, and jointly promote original and leading technological innovation for national strategic needs.

The third "Kejing Cup" Basketball Match