How did the precision diamond wire saw grow from its birth to maturity?

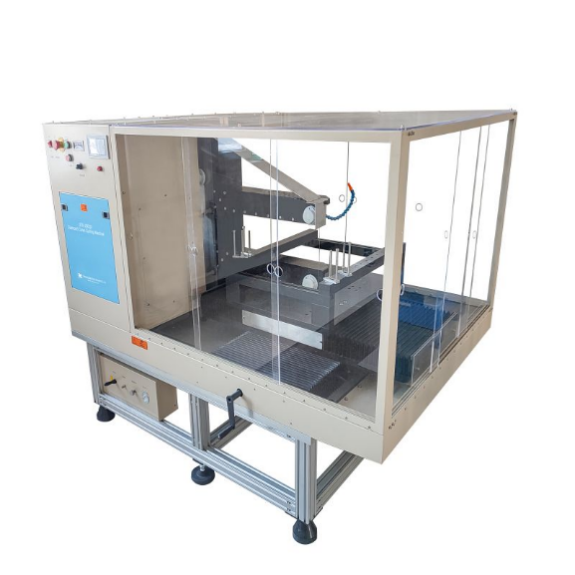

2024-07-05 11:04Our company continues to deepen its efforts in the direction of equipment automation and intelligence, and insists on independent research and development. Through our countless experiments and improvements, the precision diamond wire saw gradually took shape. In order to ensure its cutting accuracy, the team spent a lot of effort on the selection of diamond wire. They tested dozens of different diamond materials and processes, and finally selected the most suitable one. This diamond wire not only has ultra-high hardness and wear resistance, but also can remain stable under high temperature and high pressure environments, providing a solid guarantee for precision cutting. In order to improve the user experience, the team also put a lot of effort into the human-computer interaction interface of the equipment. By introducing advanced control systems and friendly operation interfaces, users can complete complex cutting tasks in just a few steps.

When we presented this precision diamond wire saw at the China Biomaterials Conference in Dalian, it immediately attracted widespread attention. Visitors gathered in front of the booth, listened carefully to the explanations and watched the on-site demonstrations. A purchasing manager from a high-end manufacturing company exclaimed: "This product not only has excellent performance, but is also very easy to use, which fully meets our expectations for precision processing tools."

The feedback from the market made the team very excited, and at the same time, they also felt a greater sense of responsibility. In order to ensure that every precision diamond wire saw that leaves the factory can meet the highest standards, our precision diamond wire saw strictly controls quality during the production process, and no detail is missed. From the purchase of raw materials to the inspection of finished products, each process is strictly supervised by professional technicians to ensure the quality of the precision diamond wire saw.

As the precision diamond wire saw gradually enters the market, we have received feedback from many users. During a customer return visit, the head of a scientific research institute excitedly shared their experience with us. "Using this precision diamond wire saw, the experimental efficiency has been greatly improved. It not only has high cutting accuracy, but also is easy to operate and has low maintenance costs. This is really an excellent tool."

In order to better serve customers, Shenyang Kejing has set up an open professional laboratory equipped with excellent professional technicians. Here, you can not only provide personalized product experience, but also get professional operation guidance. Since the establishment of Shenyang Kejing, thousands of samples have been prepared and more than 100 customers have visited, including many visits from foreign friends. Here, all employees sincerely welcome your visit and hope that you can put forward valuable opinions and suggestions.