A Brief Analysis of Diamond Wire Cutting Technology and Industry Trends

2024-05-29 17:32At present, as early as 2016, the global monocrystalline silicon wafer producers have basically switched all traditional mortar cutting (silicon carbide powder, steel wire, polyvinyl alcohol mixture) to diamond wire saw, which has greatly reduced the cost of monocrystalline silicon wafers, resulting in a certain cost-effectiveness advantage in the competition with multicrystalline silicon wafers. Therefore, multicrystalline silicon wafers must all switch to diamond wire slicing as soon as possible. Multicrystalline silicon wafer companies that do not switch will face the dilemma of being unable to survive.

Diamond cutting wire technology is currently divided into two main types, namely resin diamond wire and electroplated diamond wire. The main difference between electroplated diamond wire and resin diamond wire is the fixing method of diamond particles and the difference in coating. Resin diamond wire uses resin as the wrapping material, and electroplated diamond wire uses metal coating (generally nickel and nickel-cobalt alloy) as a binder. Both have their own advantages and disadvantages in terms of production cost and durability.

As a new cutting technology, diamond wire saw technology has the advantages of improving the cutting rate, reducing silicon wafer loss, and reducing sewage discharge, which can greatly reduce the cost of silicon wafer manufacturers. At present, diamond wire saw technology is gradually replacing the old mortar cutting technology in the silicon wafer production industry.

Diamond wire saw development status:

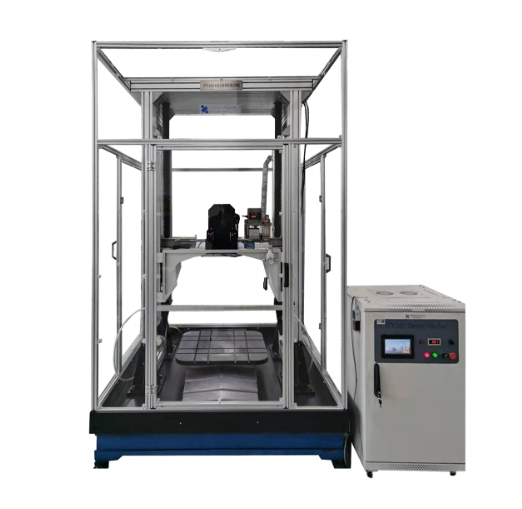

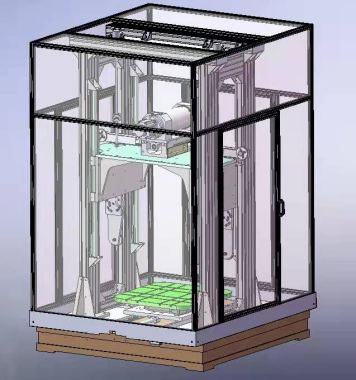

At present, domestic silicon wafer multi-wire cutting equipment is still dominated by foreign brands. After more than ten years of continuous innovation and improvement, the new generation of foreign multi-wire saws have shown more superior characteristics: 1. The cutting wire used is thinner and the silicon wafer is thinner, which greatly reduces the consumption of silicon raw materials. The thickness of the silicon wafer is reduced from the original 330μm to 180-220μm. And there is still room for further development. It is possible to reduce the thickness of the silicon wafer from 180μm to 150μm in a short period of time, and the manufacturing cost will be further reduced by 25%. 2. Increase the line speed to more than 1000m/min; increase the feed speed to 1-5mm/min; and increase the production efficiency by 2-3 times. 3. Equipped with a more precise CNC system, with advanced and reasonable process control and cutting line tension control and monitoring system.

If you are optimistic about or interested in the application and future prospects of this product, please leave a message for consultation, or come to our factory for a field visit. We will provide you with the most detailed information and affordable prices. Shenyang Kejing is willing to make progress together and work together with you.