High Vacuum Spray Pyrolysis Coater for Perovskite Solar Cells

Brand Shenyang Kejing

Product origin Shenyang, China

Delivery time 10 working days

Supply capacity 50 sets

1. Electron beam evaporation coating machine for semiconductive film adopts PLC+Touch screen manual and automatic control; the rate and final thickness can be input, and PID adjustment automatically controls the evaporation power output.

2. In manual and automatic modes, electron beam evaporation coating machine for semiconductive film is under complete interlock protection to ensure the safety of personnel and equipment.

3. Electron beam evaporation coating machine for semiconductive film has universal wheels and feet for easy movement.

Introduction of high vacuum electron beam evaporation coating machine:

GSL-1800X-ZF6 high vacuum electron beam evaporation coating machine is a heating coating method that uses resistance heating to vaporize and evaporate the film material and then condense it on the substrate to form a film. This method is simple in structure, practical, and reliable in use. It is suitable for the preparation of metal single-element thin films, semiconductor thin films, oxide thin films, organic thin films, etc. It can be used by scientific research units to conduct research on new materials and new process thin films, and can also be used for test work before mass production. High vacuum electron beam evaporation coating machine is suitable for the preparation of perovskite materials, two-dimensional materials, photovoltaic solar cell devices, etc.

Advantages of vacuum spray pyrolysis coater for perovskite thin film:

1. Vacuum spray pyrolysis coater for perovskite thin film is mainly composed of metal source evaporation deposition chamber, vacuum exhaust system, vacuum measurement system, organic evaporation source, inorganic evaporation source, sample stage system, electronic control system, gas distribution system and other parts.

2. Vacuum spray pyrolysis coater for perovskite thin film is easy to operate, the film produced has high purity and good quality, the film thickness can be accurately controlled, the film forming rate is fast, the efficiency is high, clear graphics can be obtained with the mask, and the film growth is relatively simple.

3. Vacuum spray pyrolysis coater for perovskite thin film can quickly restore vacuum work, and the atmosphere can be 5×10-4Pa≤15 minutes.

Technical parameters of electron beam evaporation coating machine for semiconductive film:

| Product name | GSL-1800X-ZF6 Vacuum Spray Pyrolysis Coater for Perovskite Thin Film | |

| Product model | GSL-1800X-ZF6 | |

| Installation conditions | 1. Electricity: a. Three-phase five-wire system. Five-wire: 380 VAC (+/-5%), 50Hz, three live wires, one ground wire, and one neutral wire. Maximum power 8KW, maximum current 32A. b. In addition, an independent shell grounding wire is required. 2. Water: Flow rate 15-20 liters/minute, 15 to 25 degrees Celsius, water inlet and outlet pressure difference 1 to 2 kg, water inlet pressure 2~3 kg, the outer diameter of the water inlet and outlet of the equipment is 12mm (it is recommended to use a better rubber water pipe); it is recommended to install a ball valve in front of the water inlet of the equipment, so that the water pressure and water flow can be easily adjusted. 3. Gas: a. Compressed air: dry, clean, water-free, oil-free compressed air, 8mm plastic air pipe, pressure 5.5-6 kg (0.55-0.6MPA). b. Ordinary nitrogen: dry nitrogen, used to break the vacuum in the equipment chamber. 8mm plastic air pipe, pressure 1-2 kg (0.1-0.2MPA). | |

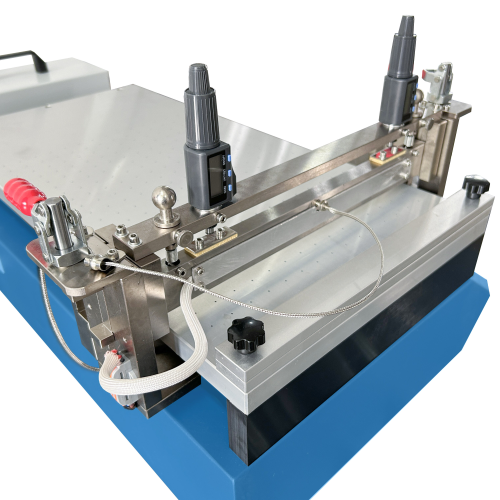

| Main features | I. Vacuum chamber: 1. Vacuum-specific 304 stainless steel chamber, internal electropolishing, vacuum chamber diameter is about 400mm wide, 400mm deep, and 450mm high, with vertical front and rear door structure. 2. The front door rail adopts imported double rail design, with a more coordinated appearance and manual locking. The rear door adopts a manual hinge structure, which is easy to tighten and seal; the system provides a stainless steel liner with a multi-piece structure for easy disassembly and installation. The inner and outer surfaces of the vacuum chamber are polished. The chamber is equipped with equipment interfaces such as lighting and film thickness gauges; 3. The left side of the vacuum chamber is connected to the main valve and molecular pump, and the vacuum measurement interface. The top is equipped with a rotating water-cooled sample stage, a sample stage baffle and a film thickness gauge probe interface; the bottom plate is equipped with 2 sets of metal evaporation electrodes, 4 sets of organic sources, and 2 film thickness gauge probe installation ports; 4. Front and rear doors with glass observation windows: 1 4-inch diameter observation window with baffle on the front door of the vacuum chamber; equipped with anti-fouling glass; 2 small observation windows on the rear door observe the source and sample respectively, equipped with anti-fouling glass. II. Evaporation source: equipped with both metal evaporation source and non-metal evaporation source III. Complete alarm system: water shortage and undervoltage detection and protection, phase sequence detection and protection, temperature detection and protection, vacuum system detection and protection. Alarm for abnormal conditions such as water shortage, overcurrent, overvoltage, and circuit breakage of pumps and electrodes, and implement corresponding protection measures; complete logic program interlocking protection system. IV. Control method: Panasonic PLC+touch screen manual automatic control; rate and final thickness can be input, PID adjustment automatically controls the evaporation power output. Control content: mechanical pump, molecular pump, pneumatic, electromagnetic valve, vacuum gauge, etc.; automatic vacuuming, automatic coating, automatic exhaust, etc.; Complete interlock protection (hardware, software interlock), in manual and automatic modes, the equipment is under complete interlock protection to ensure the safety of personnel and equipment. In addition, the system is equipped with a water flow detection alarm device. V. Structural features: The system has universal wheels and feet for easy movement. (As shown in the figure) VI. Details: A molecular sieve is installed in front of the mechanical pump, and protective parts such as filters and shutters are installed at the air outlet. The gas path is designed to avoid dust. The organic source is installed independently inside. All sample stages, source baffles, and sample stage rotations are sealed with magnetic fluid to ensure the long-term stability of the system. Relays, terminal blocks, water pipe and gas pipe joints, solenoid valves and other small components are all high-quality genuine products. | |

| Main parameters | Vacuum part | 1. Vacuum system: Using FF-200/1300 caliber of Zhongke Keyi grease-lubricated molecular pump, pumping speed: 1300 L/S + Feiyue VRD-16 mechanical pump vacuum system, 8-inch pneumatic flapper valve, vacuum measurement: one low and one high vacuum gauge (range from atmosphere to 3E-9torr), automatic control switching of low vacuum and high vacuum measurement. Vacuum readings are input into PLC for process control. Vacuum valve: Model: 2 sets of DN40mm flapper valves; 1 set of Zhongke Keyi DN200 pneumatic main valve. Vacuum seal: detachable static seal is sealed with fluororubber ring; infrequently disassembled static seal is sealed with oxygen-free copper. 2. Vacuum limit: Better than 2.0×10-5Pa. Leakage rate: Better than 5×10-8Pa*L/S (national standard). After shutting down for 12 hours, the vacuum degree is ≤5Pa. 3. Pumping speed: Pumping time: atmospheric pressure ~ 5×10-4Pa less than 20min |

| Sample stage | 1. Drawer-type structure, carrying a maximum sample of 150*150mm, equipped with a pneumatic substrate baffle. 2. The distance between the substrate and the evaporation source is electrically adjustable, and the maximum distance of the electric lifting adjustment is 60mm. 3. The sample stage is rotatable with water cooling function: the rotation speed of the sample stage is continuously adjustable from 0 to 30 rpm. | |

| Evaporation source and power supply | 1. High vacuum electron beam evaporation coating machine is equipped with 2 sets of boat-type evaporation sources. The metal source adopts a water-cooled copper electrode + evaporation boat structure (maximum temperature 1500 degrees). High vacuum electron beam evaporation coating machine is equipped with a 2.4kw evaporation power supply. The evaporation source power supply has two drive modes: Constant current and constant voltage, which can be switched. The evaporation power supply can be controlled by software or manually. The evaporation power supply can also automatically adjust the evaporation rate through the film thickness meter pid (closed loop control). With digital display. 2. High vacuum electron beam evaporation coating machine is equipped with 4 sets of organic evaporation beam source furnaces, 4 organic evaporation power supplies, organic evaporation sources with temperature display function, and organic beam source furnaces use japanese conductive temperature controllers. Equipped with 4 sets of crucibles, heating temperature: 0-700 degrees celsius; adjustable angle range: 0-15 degree, | |

| Film thickness control system | 1. Power supply: DC 5V (±10%), maximum current 400mA. 2. Frequency resolution: ±0.03Hz. 3. Film thickness resolution: 0.0136Å (aluminum). 4. Film thickness accuracy: ±0.5%, depending on process conditions, especially sensor position, material stress, temperature and density. 5. Measurement speed: 100ms-1s/time, adjustable. 6. Measuring range: 500000Å (aluminum). | |

Standard accessories for electron beam evaporation coating machine for semiconductive film:

| NO. | Name | Qty | Picture |

| 1 | Organic material evaporation power supply | 4 sets | -- |

| 2 | Inorganic material evaporation power supply | 2 sets | -- |

| 3 | Film thickness monitoring system | 1 set | -- |

| 4 | Molecular pump | 1 set | -- |

| 5 | Chiller | 1 set | -- |

| 6 | Polyester PU tube (Ø8, 6, 4mm) | 10m | -- |

About us:

Shenyang Kejing Auto-instrument Co., has been established for 25 years. So far, the company has hundreds of products and related consumables in the fields of material cutting, grinding, polishing, coating, stirring, rolling, sintering, analysis, etc., which can meet the needs of complete sample preparation and analysis of crystals, ceramics, glass, rocks, minerals, metal materials, refractory materials, composite materials, biomaterials, etc.