Glove Box Vacuum Coating All-in-one Machine for Solar Cell Perovskite

Brand Shenyang Kejing

Product origin Shenyang, Liaoning

Delivery time 10 working days

Supply capacity 50 sets

1. Perovskite solar cell connected single coating machine glove box is equipped with 6 sets of evaporation sources, which can be evaporated and switched between up to 6 materials, or co-evaporated 2 materials at the same time.

2. The perovskite solar cell connected single coating machine glove box can be docked with the glove box for easy operation in the glove box, and adopts a front sliding door structure.

3. Perovskite solar cell connected single coating machine glove box is suitable for various materials such as perovskite materials, two-dimensional materials, and device preparation of photovoltaic solar cells.

Perovskite solar glove box introduction:

GSL-1800X-ZF6 perovskite solar glove box is a heating coating method that uses resistance heating to vaporize and evaporate the film material and then condense it on the substrate to form a film. This method is simple in structure, practical, and reliable in use. It is suitable for preparing metal single-element thin films, semiconductor thin films, oxide thin films, organic thin films, etc. Perovskite solar glove box can be used by scientific research units to conduct research on new materials and new process thin films, and can also be used for test work before mass production.

Perovskite solar glove box is equipped with 6 sets of evaporation sources, which can switch up to 6 materials by evaporation, and can also evaporate 2 materials at the same time, such as: Cu、Ag、 PbI2、CsBr and other materials; the equipment can be docked with the glove box for easy operation in the glove box, and adopts a front sliding door structure. This series of perovskite solar glove box is widely used in teaching, scientific research experiments in colleges and universities, scientific research institutes, and early exploratory experiments and new product development of production-oriented enterprises.

Perovskite solar glove box is suitable for the device preparation of perovskite materials, two-dimensional materials, photovoltaic solar cells, etc.

Advantages of perovskite solar cell glove box:

1.Perovskite solar cell glove box is mainly composed of metal evaporation deposition chamber, vacuum exhaust system, vacuum measurement system, organic evaporation source, inorganic evaporation source, sample stage system, electronic control system, gas distribution system and other parts.

2.The film made by perovskite solar cell glove box has high purity and good quality, the film thickness can be accurately controlled, the film forming rate is fast, the efficiency is high, clear graphics can be obtained with mask, and the growth of film is relatively simple.

3.Perovskite solar cell glove box restores working vacuum quickly, and the atmosphere is ≤15 minutes to 5×10-4Pa.

Technical parameters of perovskite solar cell glove box:

| Product name | GSL-1800X-ZF6 Vacuum Spray Pyrolysis Coater for Perovskite Thin Film | |

| Product model | GSL-1800X-ZF6 | |

| Installation conditions | 1. Electricity: a. Three-phase five-wire system. Five-wire: 380 VAC (+/-5%), 50Hz, three live wires, one ground wire, and one neutral wire. Maximum power 8KW, maximum current 32A. b. In addition, an independent shell grounding wire is required. 2. Water: Flow rate 15-20 liters/minute, 15 to 25 degrees Celsius, water inlet and outlet pressure difference 1 to 2 kg, water inlet pressure 2~3 kg, the outer diameter of the water inlet and outlet of the equipment is 12mm (it is recommended to use a better rubber water pipe); it is recommended to install a ball valve in front of the water inlet of the equipment, so that the water pressure and water flow can be easily adjusted. 3. Gas: a. Compressed air: dry, clean, water-free, oil-free compressed air, 8mm plastic air pipe, pressure 5.5-6 kg (0.55-0.6MPA). b. Ordinary nitrogen: dry nitrogen, used to break the vacuum in the equipment chamber. 8mm plastic air pipe, pressure 1-2 kg (0.1-0.2MPA). | |

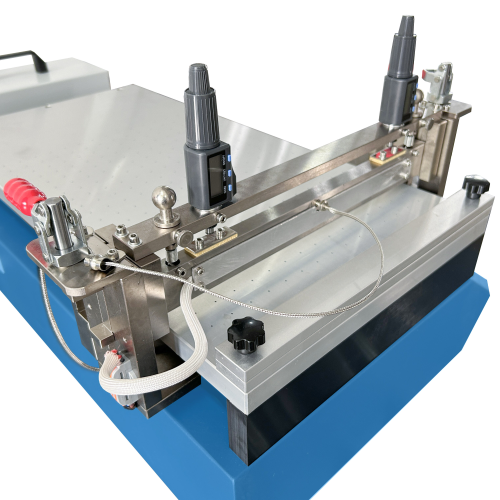

| Main features | I. Vacuum chamber: 1. Vacuum-specific 304 stainless steel chamber, internal electropolishing, vacuum chamber diameter is about 400mm wide, 400mm deep, and 450mm high, with vertical front and rear door structure. 2. The front door rail adopts imported double rail design, with a more coordinated appearance and manual locking. The rear door adopts a manual hinge structure, which is easy to tighten and seal; the system provides a stainless steel liner with a multi-piece structure for easy disassembly and installation. The inner and outer surfaces of the vacuum chamber are polished. The chamber is equipped with equipment interfaces such as lighting and film thickness gauges; 3. The left side of the vacuum chamber is connected to the main valve and molecular pump, and the vacuum measurement interface. The top is equipped with a rotating water-cooled sample stage, a sample stage baffle and a film thickness gauge probe interface; the bottom plate is equipped with 2 sets of metal evaporation electrodes, 4 sets of organic sources, and 2 film thickness gauge probe installation ports; 4. Front and rear doors with glass observation windows: 1 4-inch diameter observation window with baffle on the front door of the vacuum chamber; equipped with anti-fouling glass; 2 small observation windows on the rear door observe the source and sample respectively, equipped with anti-fouling glass. II. Evaporation source: equipped with both metal evaporation source and non-metal evaporation source III. Complete alarm system: water shortage and undervoltage detection and protection, phase sequence detection and protection, temperature detection and protection, vacuum system detection and protection. Alarm for abnormal conditions such as water shortage, overcurrent, overvoltage, and circuit breakage of pumps and electrodes, and implement corresponding protection measures; complete logic program interlocking protection system. IV. Control method: Panasonic PLC+touch screen manual automatic control; rate and final thickness can be input, PID adjustment automatically controls the evaporation power output. Control content: mechanical pump, molecular pump, pneumatic, electromagnetic valve, vacuum gauge, etc.; automatic vacuuming, automatic coating, automatic exhaust, etc.; Complete interlock protection (hardware, software interlock), in manual and automatic modes, the equipment is under complete interlock protection to ensure the safety of personnel and equipment. In addition, the system is equipped with a water flow detection alarm device. V. Structural features: The system has universal wheels and feet for easy movement. (As shown in the figure) VI. Details: A molecular sieve is installed in front of the mechanical pump, and protective parts such as filters and shutters are installed at the air outlet. The gas path is designed to avoid dust. The organic source is installed independently inside. All sample stages, source baffles, and sample stage rotations are sealed with magnetic fluid to ensure the long-term stability of the system. Relays, terminal blocks, water pipe and gas pipe joints, solenoid valves and other small components are all high-quality genuine products. | |

| Main parameters | Vacuum part | 1. Vacuum system: Using FF-200/1300 caliber of Zhongke Keyi grease-lubricated molecular pump, pumping speed: 1300 L/S + Feiyue VRD-16 mechanical pump vacuum system, 8-inch pneumatic flapper valve, vacuum measurement: one low and one high vacuum gauge (range from atmosphere to 3E-9torr), automatic control switching of low vacuum and high vacuum measurement. Vacuum readings are input into PLC for process control. Vacuum valve: Model: 2 sets of DN40mm flapper valves; 1 set of Zhongke Keyi DN200 pneumatic main valve. Vacuum seal: detachable static seal is sealed with fluororubber ring; infrequently disassembled static seal is sealed with oxygen-free copper. 2. Vacuum limit: Better than 2.0×10-5Pa. Leakage rate: Better than 5×10-8Pa*L/S (national standard). After shutting down for 12 hours, the vacuum degree is ≤5Pa. 3. Pumping speed: Pumping time: atmospheric pressure ~ 5×10-4Pa less than 20min |

| Sample stage | 1. Drawer-type structure, carrying a maximum sample of 150*150mm, equipped with a pneumatic substrate baffle. 2. The distance between the substrate and the evaporation source is electrically adjustable, and the maximum distance of the electric lifting adjustment is 60mm. 3. The sample stage is rotatable with water cooling function: the rotation speed of the sample stage is continuously adjustable from 0 to 30 rpm. | |

| Evaporation source and power supply | 1. High vacuum electron beam evaporation coating machine is equipped with 2 sets of boat-type evaporation sources. The metal source adopts a water-cooled copper electrode + evaporation boat structure (maximum temperature 1500 degrees). High vacuum electron beam evaporation coating machine is equipped with a 2.4kw evaporation power supply. The evaporation source power supply has two drive modes: Constant current and constant voltage, which can be switched. The evaporation power supply can be controlled by software or manually. The evaporation power supply can also automatically adjust the evaporation rate through the film thickness meter pid (closed loop control). With digital display. 2. High vacuum electron beam evaporation coating machine is equipped with 4 sets of organic evaporation beam source furnaces, 4 organic evaporation power supplies, organic evaporation sources with temperature display function, and organic beam source furnaces use japanese conductive temperature controllers. Equipped with 4 sets of crucibles, heating temperature: 0-700 degrees celsius; adjustable angle range: 0-15 degree, | |

| Film thickness control system | 1. Power supply: DC 5V (±10%), maximum current 400mA. 2. Frequency resolution: ±0.03Hz. 3. Film thickness resolution: 0.0136Å (aluminum). 4. Film thickness accuracy: ±0.5%, depending on process conditions, especially sensor position, material stress, temperature and density. 5. Measurement speed: 100ms-1s/time, adjustable. 6. Measuring range: 500000Å (aluminum). | |

| Glove box parameters | I. Box 1. A stainless steel box with the size of 2440mm (length) X780mm (width) X900mm (height) is divided into two sections connected by middle flanges. A flange interface is reserved on the back to be connected to the coating machine (the coating machine is provided by the customer, the flange opening size). The material is SUS304 stainless steel and the thickness is 3 mm. 2. Lift-up detachable safety glass window, inclined design operating surface, tempered glass thickness of 10 mm. 3.4 butyl rubber gloves. 4. There are 10 KF40 standard interfaces reserved. 5. Equipped with double stainless steel shelves. 6. Safety valves, protective equipment and materials in the glove box. 7. Steel structural bracket, 914mm high, equipped with universal casters. II. Transition cabin 1. A large transition position. 1)Material: SUS304 stainless steel. 2)size: Φ360X600mm. 3)Location: Right side of the box. 4)Connection method: sealed flange connection. 5)Transfer method: By moving the tray, the tray is easy to disassemble, making it convenient to transfer large materials 6)Operation method: a) Manual operation: Touch the valve through the touch screen. b) Automatic operation: It has automatic pumping and charging functions. Users only need to touch the start button on the touch screen, and the PLC automatically completes multiple pumping and charging procedures to standardize operations, save time and improve work efficiency. Users can set the number of times of pumping, each pumping time and inflation pressure. 2. Two small transition warehouses: 1)Material: SUS304 stainless steel. 2)size: Φ155X320mm. 3)Location: Right and left sides of the box. 4)Connection method: sealed flange connection. 5)Transfer method: By moving the pallet. 6)Operation method: Manual operation through three-way ball valve. III. Gas purification system. 1. A gas purification column: 1)High-performance copper catalysts and molecular sieves that are most suitable for glove box gas purification were selected for water and oxygen removal. 2)The adsorption capacity of oxygen and water is 60 liters and 2 kilograms respectively. 2. After the gas purification column is saturated with adsorption, it is regenerated with hydrogen-containing nitrogen or argon to restore its adsorption capacity 1)Use hydrogen/nitrogen mixture as regeneration gas. H2:5%; N2:95%。 2)Due to the ultra-low leakage rate of the glove box, the purification column is regenerated frequently about once a year. 3. A circulating fan. 1)The flow rate is 90m3/h. 4. Organic solvent adsorption column. 1)Adsorption material containing activated carbon particles. 5. Electro-pneumatically controlled circulation main valve, KF40 standard interface. 6. All gas paths are controlled by solenoid valves, and the regeneration of the purification column is fully automatically controlled. 7. Gas filters are installed at the inlet and outlet of the circulation system. IV. Control system: 1. The control system consists of imported PLC and 7 "color touch screen, with Chinese and English operating interfaces. 2. Implement the following control functions: 1)Automatic control of tank pressure. a) Users can set the working pressure range arbitrarily between +10 and-10 millibars, and the PLC will automatically regulate the tank pressure within the set range. The default value for the operating pressure range is 0 to +5 millibars. b) When the tank pressure is greater than 12 millibars, the PLC automatically opens the safety valve to relieve pressure to protect gloves, equipment and materials in the tank. c) Use the foot switch to finely adjust the box pressure. 2)One-click enables multiple pumping and inflation operations in the transition cabin, saving time a) The user can set the number of pumping times, each pumping time and inflation pressure, and then start the automatic pumping program to automatically complete the pumping within the set time. 3)Leak rates can be monitored manually. a) Set manual testing: Just press the start testing button, and the PLC will automatically test the tightness of the box and report the leakage rate of the box. 4)Automatic gas cleaning function in the box a) The user sets the cleaning time, then touches the start button on the screen, and the system will start cleaning the box, and it will automatically stop at the set time. 5)The system's historical data is automatically recorded and displayed, and data within a specific time, such as tank pressure, water content and oxygen content, can also be exported using the USB flash drive. 6)Display operating errors and prompts. 7)Automatic alarm for box atmosphere. 8) All operations have preset conditions, and the actions are interlocked to prevent unsafe operations from damaging the equipment or destroying the atmosphere inside the box. 5. Technical indicators: 1. Leakage rate <0.02vol%/h. 2. H2O﹤1ppm ,O2﹤1ppm. 6. Other annexes: 1. An oxygen analyzer. 1. The measurement range can be set: 0-1000ppm. 2. Accuracy: 1% of the range or 0.2ppm. 3. Installation location: Kejing's oxygen sensor is installed on the box. Regardless of whether the gas is circulated or not, the oxygen sensor continuously detects the atmosphere in the box and displays the oxygen content in the glove box. 4. Sensor: Zirconia battery has the advantages of accurate zero point and small drift. 5. Display: The output of the analyzer is connected to the PLC, and the detected value is displayed on the touch screen, and the alarm value can be set. 6. Control: Kejing adopts real-time monitoring function to ensure and quickly purify oxygen at all times, and to ensure the oxygen content calibration value set by the customer in the fastest time. 7. Calibration method: Accurately detecting the oxygen content in the glove box is crucial. Kejing also provides users with a calibration method for the analyzer, so that the analyzer can accurately detect the concentration of impurities in the glove box and avoid erroneous readings on the experiment. The results affect and waste the user's valuable time and materials. 2.1 Taiwan Water Analyzer 1)Measuring range: 20℃ to-100℃ (dew point), 2)Accuracy: 2℃. 3)Display: The output of the analyzer is connected to the PLC, the detected value is displayed on the touch screen, and the alarm value can be set. 4)Control: Like the oxygen analyzer, the gas circulation system can be automatically controlled according to the user's settings to achieve automatic circulation. 4. The power interface in the box is equipped with a porous socket. 5. 1 vacuum valve. VII. Acceptance method Using 99.999% inert gas source, the tank is operated empty, and the water oxygen content in the tank is less than 1PPM. | |

Standard accessories of Perovskite solar cell connected single coating machine glove box:

| Project | Units | Number | Model | Made in | Remarks |

| Vacuum chamber, piping | Only | 1 | 400×400×H450mm; mirror polishing of cavity | Shenyang Kejing | Surface polishing treatment |

| Main valve | Only | 1 | DN200 | Zhongke Keyi | Pneumatic, connecting vacuum chamber and main pump |

| Prestage, bypass | Only | 2 | 40 Pneumatic flapper valve | Shenyang Kejing | |

| Mechanical pump | Taiwan | 1 | VRD-16 | Feiyue | Pre-stage + pre-draw |

| Molecular pump | Taiwan | 1 | FF200/1300 | Zhongke Keyi | |

| Inflation valve | Taiwan | 1 | 6mm | Qixing Huachuang | |

| Interface | Batch | 1 | Reserve leakage detection reservations such as KF-40/25 | Chengdu Ruibao | |

| Vacuum gauge | Set | 1 | One low and one high | Shenyang Kejing | |

| Evaporation electrode | Set | 2 | Both groups of evaporation sources have water cooling function | Shenyang Kejing | |

| Metal evaporation power supply | Set | 1 | 2.4KW | Shenyang Kejing | |

| Organic source | Set | 4 | 700℃ | Shenyang Kejing | |

| Organic power supply | Set | 4 | 20-10 | Shenyang Kejing | |

| Sample stage | Set | 1 | Water cooled 150*150mm | Loongrise | |

| magnetic fluid | Set | 6 | Single shaft with gasket | Shenyang Kejing | |

| Seal other accessories | Set | 1 | Equipment specifications required | Panasonic PLC | |

| Electrical control system | Set | 1 | PLC+ touch screen Panasonic manual automatic control | Shenyang Kejing | |

| Electric control cabinet | Set | 1 | be integral | Shenyang Kejing | |

| Main frame | Set | 1 | Surface blow molding of carbon steel welded frame | Shenyang Kejing | |

| Mask plate | Set | 1 | Customized on demand with an accuracy of more than 0.1mm | Shenyang Kejing |