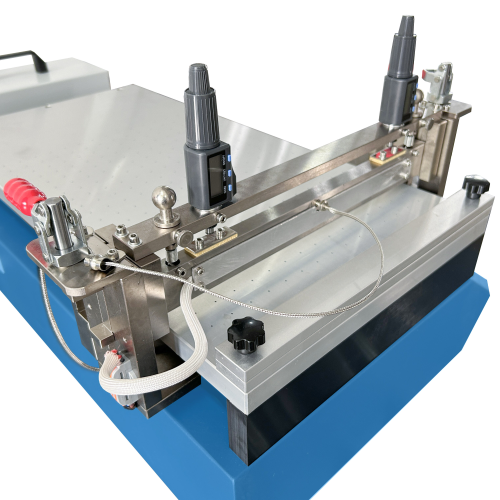

Film Coater With Heatable Vacuum Bed And Doctor Blade

Brand Shenyang Kejing

Product origin Shenyang, China

Delivery time 10 working days

Supply capacity 50 sets

1. The coating speed of the film coater with heatable vacuum bed is adjustable between 10 - 100mm /s.

2. This equipment uses vacuum adsorption to fix the substrate, so that the substrate will not wrinkle during the coating process,

3. Maximum heating temperature at the bottom: 200℃

Introduction of automatic film coater with heatable vacuum bed:

MSK-AFA-II-VC-FH automatic film coater with heatable vacuum bed is a CE-certified equipment with a heating temperature of up to 200 ° c. Automatic film coater with heatable vacuum bed uses vacuum adsorption to fix the substrate, so that the substrate will not wrinkle during the coating process, making the coating smoother. The automatic film coater with heatable vacuum bed is equipped with a precision adjustable film device. The moving push rod pushes it at a constant speed to achieve uniformity of slurry coating on the substrate. This automatic film coater with heatable vacuum bed is especially suitable for making battery pole pieces, high-temperature polymer films and conductive ceramic films.

Advantages of heated vacuum doctor blade film coater:

1. Heated vacuum doctor blade film coater is small and takes up no area, suitable for research equipment for laboratory use

2. The heated vacuum doctor blade film coater control panel is partially simple and easy to operate.

3. The heated vacuum doctor blade film coater has an emergency stop switch that can stop working in time if problems occur in the coating process to prevent waste of raw materials.

4. The heated vacuum doctor blade film coater uses bottom heating. Compared with the film prepared by heating the top cover, the film is less likely to bubble and crack when heated and dried.

Technical parameters of heated vacuum doctor blade film coater:

Product name | MSK-AFA-II-VC-FH Heated Vacuum Doctor Blade Film Coater |

Product model | MSK-AFA-II-VC-FH |

| Main parameters |

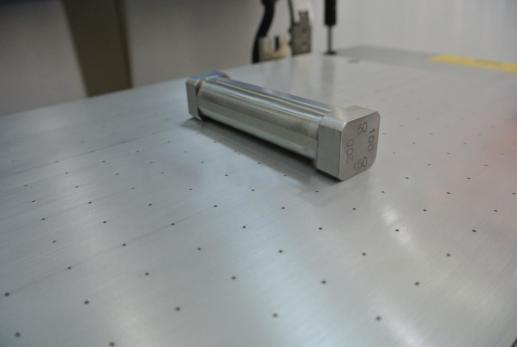

② Selection 1. The width size of our company's existing scrapers are: 50mm, 100mm, 150mm, 180 and 250 mm. 2. The width of the coating surface is 200 mm, and the width of the optional blade cannot exceed this value. 3. If the coating amount is relatively small and meets the following four fixed thicknesses, you can choose our four-sided film maker. The effective coating width is 80mm, and the fixed thickness size of the four sides is 5μm, 10μm, 15μm, and 20μm respectively.  7. Vacuum connection: This equipment uses vacuum adsorption to fix the substrate, so that the substrate will not wrinkle during the coating process. Our company has a variety of vacuum pumps to choose from. Vacuum pump is optional equipment. 8. Overall size: 805mm(L) x 475mm(W) x 235mm(H). 9. Weight: 30Kg .  |

Company introduction:

Today, we have hundreds of products covering grinding and polishing, heating furnaces, Automatic film coater for battery electrode coating, coating machines and related consumables, which can meet the full range of needs for the preparation and analysis of crystals, ceramics, glass, petrographic phases, mineral samples, metal materials, refractory materials and composite materials. Kejing's equipment precision and quality are on par with those of well-known foreign companies, but the price of its products is only a fraction of theirs. Automatic film coater for battery electrode coatingexcellent cost-effectiveness has attracted many customers; at the same time, due to the excellent performance of our products, Kejing's equipment is exported to many countries such as the United States, Europe, and Japan, and has been recognized by them.