Wafer Puncher for Metals

PM200 metal wafer puncher can be used together with a distortion-free transmission electron microscope (TEM) when preparing samples. The product punches the metal disc to obtain the required sample, which reduces the difficulty of manual manufacturing as well as the preparation time. The product is used to prepare wafers of 3mm diameter, and is mainly used for metal materials with extensibility and good toughness. Compared with similar products on the market, PM200 metal wafer puncher has better repeatability and higher dimensional accuracy when preparing wafer samples of the same size, and the service life is several times that of similar products. PM200 metal wafer puncher is made of light aluminum alloy as the base, and the surface is treated with special sandblasting oxidation, which makes it very smooth when touched. The punch head is made of die steel and its surface hardness and wear resistance are improved after heat treatment, therefore the service life is greatly increased. The product uses a lever structure to reduce the force of the operator and is ergonomic friendly. If wafers of special sizes are required, the puncher can be customized individually.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Main Features

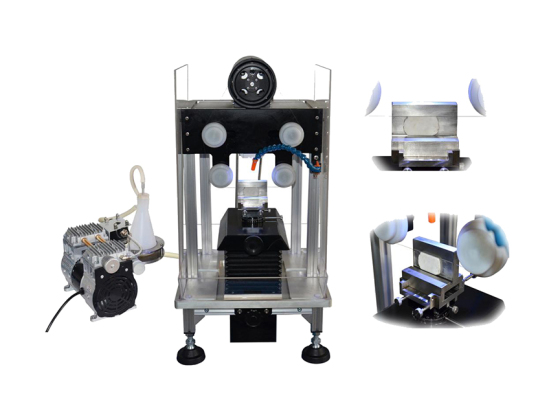

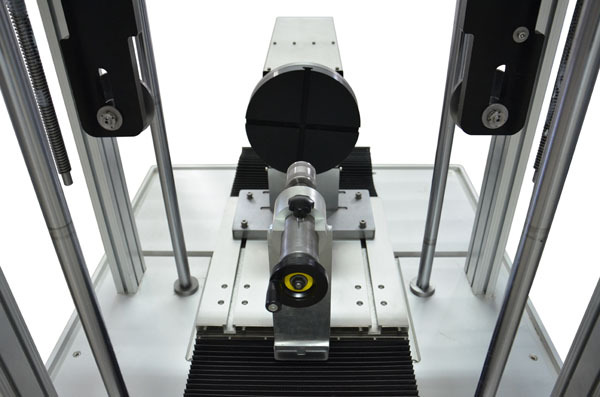

1. It can used either "vertically" or "horizontally", and enables single punching and multiple continuous punching onto the samples.

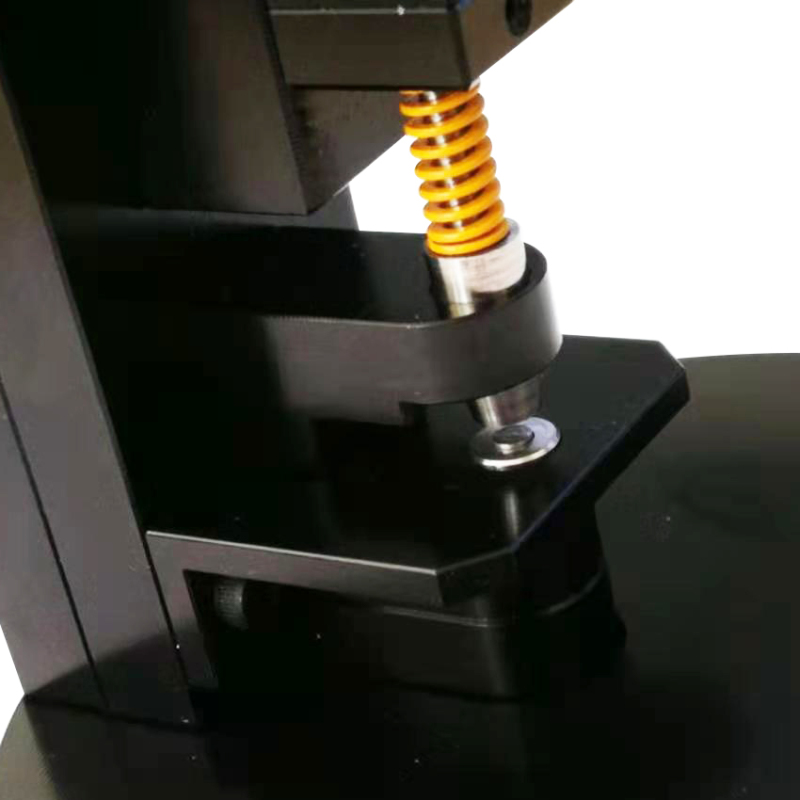

2. The punch head is made of high-quality die steel, and after CNC precision machining, it has the features of high coaxiality, smooth surface, and controllable clearance.

3. The puncher base is made of aluminum alloy, and the surface is anodized, which is light in weight and fadeless in color.

4. The lever-type punching method with moderate force and appropriate resilience makes it easy to press and fit.

5. With automatic unloading mechanism, the sample is automatically ejected after punching.

6. When running horizontally, the material is automatically received, and continuous punching can be performed.

Technical Parameters

Product name | PM200 metal wafer puncher |

Product model | PM200 |

Major parameters (specification) | 1. sample size: φ3mm 2. disc thickness: 50-120um 3. punching times: 20000 times 4. product weight: 0.5Kg |

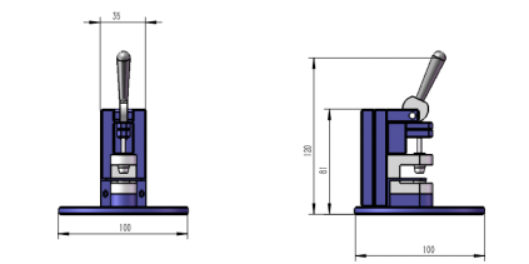

Product dimension | Dimension: 100mm*100mm*120mm

|

cautions | 1. The metal disc is placed on the plane of the lower die base of the puncher. 2. Press the pressure rod downward until the punch head and the lower die base are pressed tightly. 3. when releasing the pressure rod, the spring reaction force will reset the pressure rod. If used vertically, the samples need to be taken out or shaken off manually; if used horizontally, the samples will fall down automatically. 4. When the service life comes closely to its end, the punch head may cause irregular edge due to slight wear, and the puncher needs to be replaced at this time. |

Logistics