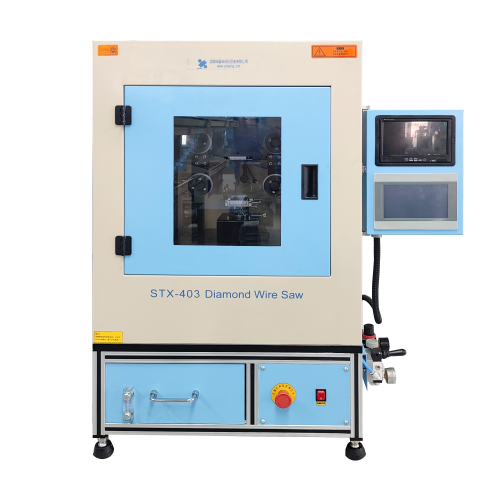

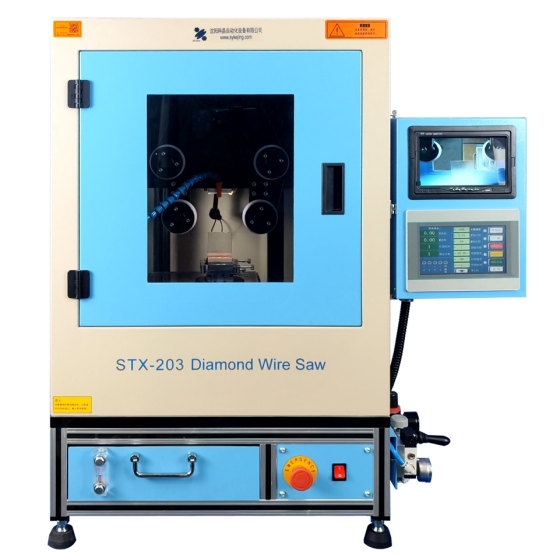

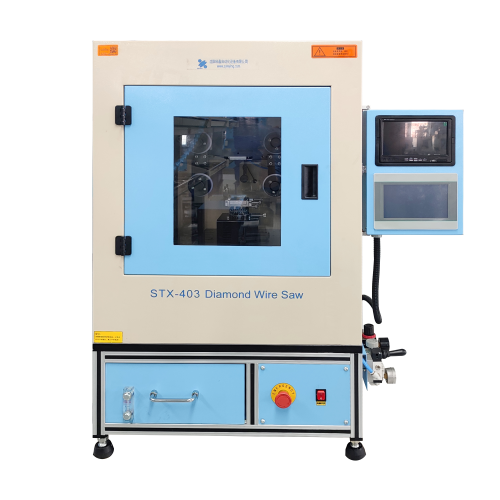

STX-403 Small Diamond Wire Cutting Machine

1.STX-403 Small precision diamond wire saw is suitable for a variety of brittle materials, especially for the needs of material researchers, and can meet the diverse cutting needs of different research fields.

2.Small precision diamond wire saw can accurately slice and cut materials, and the sample size after cutting is highly accurate, ensuring the consistency and reliability of the cutting results.

3.Small precision diamond wire saw has a fully automatic continuous feeding function, without manual adjustment, which simplifies the operation process and improves work efficiency.

- Shenyang Kejing

- Shenyang, China

- 22 working days

- 50 sets

- Information

Description of small precision diamond wire saw:

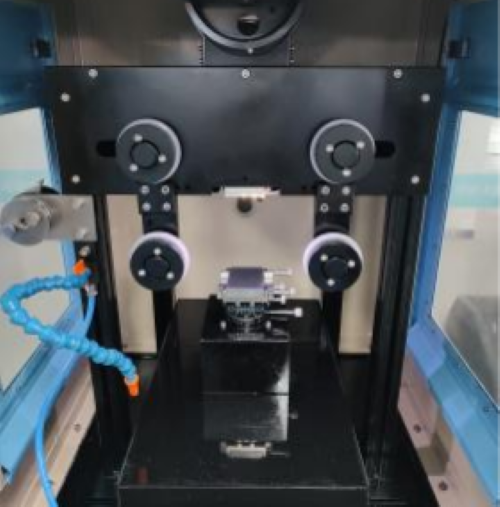

Reciprocating continuous diamond wire saw is designed for material researchers and is used for precision cutting of brittle material samples. It can slice and cut materials, and the rotating turntable can also cut samples at a certain angle. Reciprocating continuous diamond wire saw can cut materials such as ceramics, crystals, glass, metals, rocks, thermoelectric materials, infrared optical materials, composite materials, and biomedical materials. Reciprocating continuous diamond wire saw is a continuous cutting diamond wire saw. After setting the cutting program, the sample is fed continuously without manual adjustment, and the size of the cut sample is highly accurate. The cutting wire of this automatic precision diamond wire cutting machine adopts a single wire reciprocating motion mode. The length of the usable wire is long, the service life of the wire is long, and the cutting efficiency is improved. When it is used for ultra-thin precision cutting, the thickness of the cut slice (within about 1 inch) can reach 0.08mm.

Advantages of precision diamond wire saw cutting machine:

1. Precision diamond wire saw cutting machine adopts a single wire reciprocating motion mode, the cutting wire has a long service life, reduces the replacement frequency, reduces maintenance costs, and improves cutting efficiency.

2. Precision diamond wire saw cutting machine can perform ultra-thin precision cutting, and the thickness of the slices after cutting can reach 0.08mm, which is suitable for high-end applications that require ultra-thin slices, such as semiconductor materials, optical materials, etc.

3. Precision diamond wire saw cutting machine is equipped with a rotating turntable, which can realize multi-angle cutting of samples, providing more possibilities for the study of complex samples, and increasing the flexibility and application range of the equipment.

Parameters of automatic precision diamond wire cutting machine:

Product name | STX-403 Small Diamond Wire Cutting Machine |

Product model | STX-403 |

Installation conditions | 1. Temperature and humidity: 10-85%RH (at 25℃ without condensation) Temperature: 0-45℃. 2. There is no strong vibration source and corrosive gas around the equipment. 3. Coolant: required (cutting oil is recommended). 4. Power supply: single phase: AC220V 50Hz . 4. Air source (compressed air): ≥0.6Mpa. 5. Workbench size: recommended 900mm×800mm×500mm load-bearing 200kg or more (solid cement table is best). 6. Ventilation device: no special requirements. |

Function and use | 1. Ceramic materials: alumina ceramics, zinc oxide ceramics, zirconium oxide ceramics, target ceramics, honeycomb ceramics, semiconductor ceramics, conductive ceramics, non-conductive ceramics, etc.; 2. Crystal materials: graphite, silicon crystals (solar polysilicon, single crystal silicon), sapphire, alumina crystals, infrared glass crystals, alumina crystals, silicon carbide crystals, cesium iodide crystals, etc.; 3. Glass materials: chalcogenide glass, optical glass, quartz glass, infrared glass, glass tubes, etc.; 4. Metal materials: iron, aluminum, copper, titanium alloy, magnesium alloy and other metals and alloys, non-ferrous metals (zinc sulfide, ferrite), etc.; 5. Composite materials: PVC board, carbon fiber composite materials, glass fiber composite materials, etc. 6. Rock materials: precision cutting of natural rocks, jade, meteorites, Pei Cui, agate, etc., precision slicing of various high-value materials; geological light slices, geological thin slices (sedimentary rocks, igneous rocks, metamorphic rocks, ores), etc. slicing. 7. Thermoelectric materials: bismuth telluride, lead telluride, silicon-germanium alloy, etc. 8. Infrared optical materials of precision diamond wire saw cutting machine: zinc selenide, zinc sulfide, silicon, germanium and other crystals. 9. Biomedical materials: biological plastic specimen slices (human and animal organs, jaw soft and hard tissue slices, implant observation, dental crowns and bridges, teeth and other histological specimens); orthopedic soft and hard tissue slices (femur, hip joint, vertebral body and other living tissue and hard tissue, bone histological samples with implants, etc.); cardiovascular stent slices, stone slices and other medical tissue slices; Note of small precision diamond wire saw: Materials with a hardness less than diamond wire can be precisely cut. |

| Main parameters | 1. Power supply interface: AC220 50Hz 10A. 2. Total power of small precision diamond wire saw: 120W (excluding air compressor). 3. Main body structure of small precision diamond wire saw: Aluminum alloy frame sheet metal closed shell. 4. Diamond wire length (m) of reciprocating continuous diamond wire saw: ≤45m. 5. Diamond wire diameter (mm) of reciprocating continuous diamond wire saw: ≤0.45mm. 6. Diamond wire tensioning method: Adjustable pneumatic tensioning. 7. Spindle cutting rotation method: Reciprocating rotation. 8. Spindle speed of automatic precision diamond wire cutting machine: 2--300rpm adjustable. 9.Cutting speed: 0.05-40mm/min 10.Return speed:1-40mm/min 11. Z-axis effective stroke of automatic precision diamond wire cutting machine: ≤110mm. 12. Y-axis effective strokeof automatic precision diamond wire cutting machine: ≤110mm. 13. Horizontal/tilt angle of two-dimensional fixture: Manual two-dimensional fixture: horizontal 0-360°, tilt angle ±15°. 14. Max spacing between the inner sides of the two guide wheels: 145mm. 15. Max workpiece diameter and length for cutting: Φ100×100mm. 16. Sample block size of reciprocating continuous diamond wire saw (length × width × height): 120mm×51mm×12mm. 17. Cutting thickness of precision diamond wire saw cutting machine(depth): Effective value ≤100mm. 18. Control mode of small precision diamond wire saw: Integrated control, PLC programmer + 7-inch touch screen. 19. Video monitoring of cutting area: 7-inch display screen. |

20.Product specifications: ·Size: L.760mm×W760mm×H1100mm. ·Weight: about 150kg. |

Standard accessories:

NO. | Name | Quantity | Image link |

| 1 | Polyethylene (PE) tension pulley | 2 pcs |  |

| 2 | Polyethylene (PE) guide pulley | 2 pcs |  |

| 3 | Diamond wire | 3 rolls |  |

| 4 | Water pump | 1 pc |  |

| 5 | Resin ceramic block | 2 pieces |  |

| 6 | Paraffin rod | 4 sticks |  |

Optional Accessories:

| NO. | Name | Quantity | Image link |

| 1 | Diamond wire (Ø0.35mm, Ø0.42mm) | (Optional) |  |

| 2 | Special cutting oil | (Optional) |  |

| 3 | HEATER series heating platform | (Optional) |  |

| 4 | (Optional) |  | |

| 5 | Silent oil-free air compressor | (Optional) |  |

| 6 | DX-100 single crystal orientation instrument | (Optional) |  |

About us:

As a company focused on the scientific research market, our customers mainly come from colleges and universities, scientific research institutions and laboratories. We are always committed to serving the society through innovative technology, focusing on customers, and providing professional and efficient scientific research services. Our goal is to become a leader in the field of scientific research instruments that is trustworthy, respected, and has international influence and competitiveness.