Automatic Diamond Wire Saw With Electric Angle Stage

1. Electric Angle Stage Diamond Wire Saw is designed and developed by our own factory, with guaranteed accuracy. We also have a professional team to answer all your questions about the products.

2. Electric Angle Stage Diamond Wire Saws is suitable for precision cutting of brittle material samples, and can slice and cut the materials.

3. Our Electric Angle Stage Diamond Wire Saw can cut a variety of materials, such as ceramics, crystals, etc., and have a wide range of applicability.

- Shenyang Kejing

- Shenyang, China

- 22 working days

- 50 sets

- Information

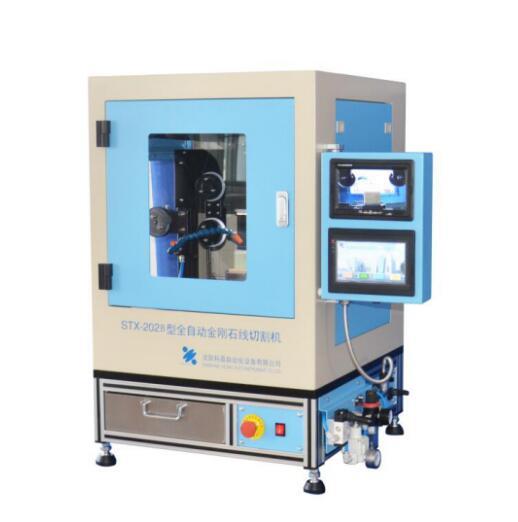

Introduction of Electric Angle Stage Diamond Wire Saw:

STX-203 Precision Electric Angle Stage Wire Saw is specially designed for material researchers. Precision Electric Angle Stage Wire Saw is used for precision cutting of fragile material samples. And the Precision Electric Angle Stage Wire Saw can slice and cut materials. The materials include ceramics, crystals, glass, metals, rocks, thermoelectric materials, infrared optical materials, composite materials, and biomedical materials.

Technical Parameters

Product Name | STX-203 Fully Automatic Diamond Wire Saw |

Product Model | STX-203 |

| Installation conditions | 1. Temperature and humidity: 10-85%RH (at 25℃ without condensation) Temperature: 0-45℃. 2. There are no strong earthquake sources and corrosive gases around the equipment. 3. Coolant: required (recommended to use --- cutting oil). 4. Power supply: single phase: AC220V 50Hz, national standard three-pole socket 10A, must be well grounded 4. Air source (compressed air): ≥0.6Mp. 5. Workbench size: 800X700X500mm is recommended, with a load capacity of 150KG or more (solid cement table is preferred) 6. Ventilation device: no special requirements. |

Major Parameters | 1. Power supply interface: National standard three-pole socket with insurance AC220 50Hz 10A 2. Total power: 120W (excluding air compressor) 3. Main body structure: aluminum alloy frame sheet metal closed shell 4. Diamond wire length (m): ≤45m 5. Diamond wire diameter (mm): ≤0.45mm 6. Diamond wire tensioning method: adjustable pneumatic tensioning 7. Spindle cutting rotation method: reciprocating rotation 8. Spindle speed: 2--300r/min adjustable 9. Z axis effective stroke: 1-60mm 10. Y axis effective stroke: 0.01-50mm 11. Rotation angle table: electric: horizontal 0-360° 12. Tilt angle table: electric: ±10°; range accuracy ±1° 13. Upper limit spacing between the inner sides of the two guide wheels: 96mm 14. Cutting workpiece diameter and length: ≤Φ50X50mm 15. Sample block size (length x width x height): 80X51X12mm 16. Cutting thickness (depth): effective value ≤50mm 17. Control mode: integrated control PLC programmer + 7-inch touch screen 18. Cutting area video monitoring: 7-inch display |

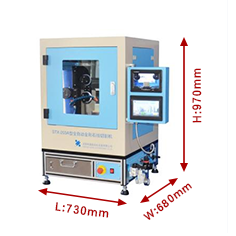

Specification of product | Outline dimension(length × width × height): 730mm ×680mm×970mm Net weight: 130kg

|

Functions and Applications | 1.Ceramic materials: aluminum oxide ceramics, zinc oxide ceramics, zirconium oxide ceramics, target ceramics, honeycomb ceramics, semiconductor ceramics, conductive ceramics, non-conductive ceramics, etc. 2.Crystal material: graphite, silicon crystal (solar polysilicon, single crystal silicon), sapphire, aluminum oxide crystal, infrared glass crystal, aluminum oxide crystal, silicon carbide crystal, cesium iodide crystal, etc. 3.Glass materials: chalcogenide glass, optical glass, quartz glass, infrared glass, glass tube, etc. 4.Metal materials: iron, aluminum, copper, titanium alloy, magnesium alloy and other metals and alloys, non-ferrous metals (zinc sulfide, ferrite), etc. 5.Composite materials: PVC board, carbon fiber composite material, glass fiber composite material, etc. 6.Rock material: precision cutting of natural rock, jade, meteorite, jadeite/emerald, agate, etc. Precision slicing of various high-value materials; geological slices, geological slices (sedimentary rocks, magmatic rocks, metamorphic rocks, ore) and other square slices 7.Thermoelectric materials: bismuth telluride, lead telluride, silicon germanium alloy, etc. 8.Infrared optical materials: zinc selenide, zinc sulfide, silicon, germanium and other crystals 9.Biomedical materials: Bioplasticized specimen slices (human and animal organs, combined sections of soft and hard jaw tissues, implant observation, dental crowns and bridges, teeth and other histological specimens); Orthopedic soft and hard tissue joint sections (femoral, hip, vertebral body and other fresh tissue and hard tissue, bone histological samples with implants, etc.); Cardiovascular and cerebrovascular stent slices, calculi slices and other medical tissue slices; … Note: Materials with a hardness less than diamond wire can be precisely cut. |

Standard Accessories

No. | name | qty | picture |

1 | Polyethylene (PE) Tension Wheel

| 2 pcs |

|

2 | Polyethylene (PE) Leading Wheel

| 2 pcs |

|

3 | 2 inch cutting 90° positioning mold | 1 set |  |

4 | Diamond Cutting Wire

| 3 rolls |

|

5 | Water Pump | 1 pcs |  |

6 | Resin Bonded Ceramics

| 2 pcs |

|

7 | Wax Bar

| 4 pcs |

|

Optional Accessories

No. | name | functional type | picture |

1 | Diamond Cutting Wire (Ø0.35, Ø0.42mm) | (optional) |

|

2 | Special oil for cutting | (optional) |  |

3 | Geological Slice Cutting Fixture | (optional) |  |

4 | MTI series heating platform | (optional) |

|

5 | Portable Microscope (3R Wireless Digital Microscope) | (optional) |  |

6 | (optional) |  | |

7 | DX-100 Single Crystal Direction-Finder | (optional) |

|

Warranty

· One year limited with lifetime support (not including rusted parts due to inadequate storage conditions)

Logistics

About us

Our Manual cylindrical sample punching machines are made of high-quality materials, and the equipment is durable and high-performance. Our company also has a strict quality control process. Before the product leaves the factory, our employees will conduct comprehensive tests to ensure the accuracy and stability of the Electric punching machine. At the same time, we also have a professional after-sales service team. If you have any questions about the product, our team will answer you in time, so that your Cylindrical specimen punching machine can operate stably for a long time.