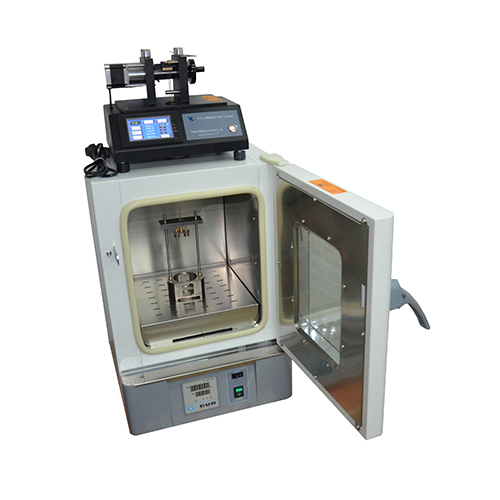

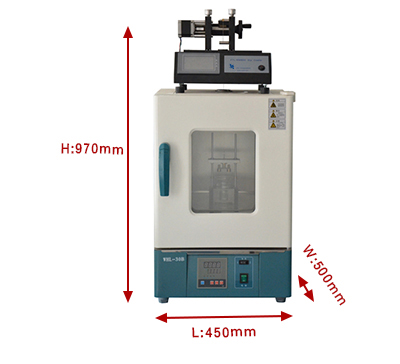

Programmable (1-200 mm/min) Dip Coater With Drying Oven

1.PTL-MMB02 millimeter constant temperature programmable control dipping coating machine adopts a color touch screen as the data input and output terminal to set parameters such as pulling speed, dipping time and speed, times of pulling and returning and drying time, etc.

2.Millimeter constant temperature programmable control dipping coating machine is equipped with a thermostatic oven, so that the film growing process can be carried out at a constant temperature, which is conductive for the solidification of the film.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Introduction of pulling dipping coating machine:

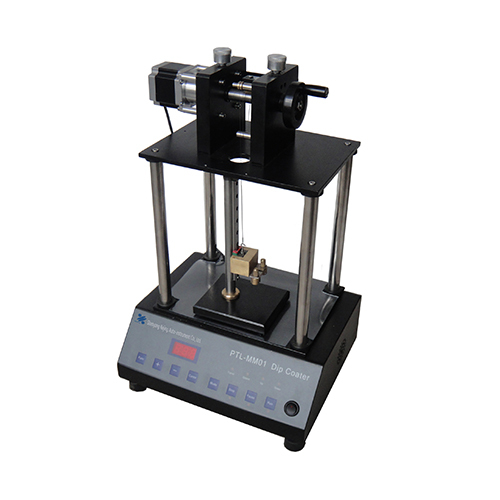

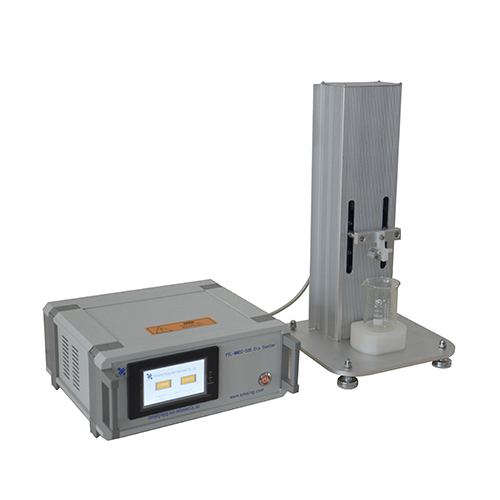

PTL-MMB02 program-controlled pulling coating machine is a CE-certified product. It is a millimeter-level precision pulling equipment designed by our company for dipping and pulling coating experiments in liquid phase. It is a necessary product equipment for liquid phase growth film research units and institutes. Pulling dipping coating machine adopts PLC program control system to control high-precision stepping motor with control actuator and pulling wire to do lifting and pulling operation. The lifting process runs smoothly and accurately; by vertically dipping and pulling samples, the samples are immersed in liquid film materials for a period of time and then pulled out, so that a certain thickness of film grows on the surface of the samples. Pulling dipping coating machine can choose two program operation modes: "single-pass operation" and "full-pass operation". The program can independently set the sample lifting speed, the descending liquid entry speed, the sample immersion residence time in the liquid film material, the sample drying time, and the number of cycles of the sample entering and exiting the liquid film material. This series of program-controlled pulling coating machines are divided into two models: PTL-MM02 normal temperature type (i.e. room temperature) and PTL-MMB02 constant temperature type with constant temperature heating drying oven. You can choose the appropriate model according to the process temperature requirements of the pulling coating growth. The Pulling dipping coating machine is small in size, simple to operate and easy to carry. It is widely used in laboratories of colleges, research institutes and corporate units.

Advantages of thermostatic vertical lift coating machine:

1. Thermostatic vertical lift coating machine is equipped with a 4.3-inch color touch screen and a simple and clear control interface, which is suitable for beginners.

2. Thermostatic vertical lift coating machine is small in size and cost-effective, saving laboratory operation space.

3. Thermostatic vertical lift coating machine uses PLC program control to drive a high-precision stepper motor, and uses suspended wire conduction and lifting technology to reduce vibration.

Technical parameters of pulling dipping coating machine:

Product Name | PTL-MMB02 Millimeter Constant Temperature Programmable Control Dipping Coating Machine |

Product Model | PTL-MMB02 |

Installation Conditions | 1. Power supply: AC220V 50/60Hz national standard 10A socket, must be well grounded. 2. Site environment: Use at temperature 25℃±15℃, humidity 55%Rh±10%Rh. |

Main Parameters (Specification) | 1. Working voltage of the lifting machine: DC24V 3.75A (standard: AC100~240V power adapter) 2. Power of the lifting machine: 50W. 3. Type: Program-controlled-constant temperature type (with constant temperature box). 4. Drive motor: high-precision stepper motor. 5. Speed setting range: 1-200mm/min. 6. Dwell time: 1-999s. 7. Drying time: 1-999s. 8. Lifting stroke: 1-75mm. 9. Number of pulls: 1-20 times. 10. Effective immersion length: 60mm. 11. Upper limit of lifting load: <100g. 12. Sample substrate size: 75mm×25mm×2.5mm. 13. Display control: 4.3-inch color touch screen. 14. Constant temperature box parameters: Working voltage: AC220V 50/60Hz. Rated current: 3.6A. Heating rated power: 0.8KW. Temperature range: RT room temperature ~ +100℃. Temperature control/setting method: digital tube double row PID/touch four button setting. Heating operation timer: 0~9999 minutes or hours. Inner dimensions (content volume): 310mm×310mm×310mm (30L). External dimensions: 428mm×500mm×723mm. |

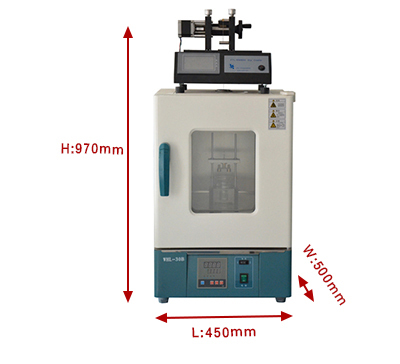

15. Product specifications: Dimensions: 428mm×500mm×995mm. Weight: ≈50kg (including constant temperature box).

| |

Note: 1. Specifications of the standard "power adapter": IN: AC100-240V 50/60Hz OUT: DC-24V 3.75A. The actual power supply of the device is subject to the label attached to the back of the product; 2. Customizable AC110V 50/60Hz constant temperature oven; | |

Standard accessories:

| NO. | Name | Qty | Image Link |

| 1 | Sample fixture | 1 set | -- |

| 2 | Loading cup | 1 pcs | -- |

| 3 | Raising wire | 3 items | -- |

Warranty:

One year limited with lifetime support (not including rusted parts due to inadequate storage conditions).

Logistics:

Company advantages:

1. We have many years of export experience and rich experience.

2. Our company has a group of R&D workers with many years of work experience. We use our rich experience to develop better products.

3. We have reached cooperation with internationally renowned logistics companies to ensure that your goods are delivered on time.

4. Our products are all brand new and unused. You can use them with confidence.

Aboout us:

In order to better serve our customers, we have established a high-quality customer service center. Customers can bring samples to our company and conduct trial production in our dedicated laboratory, which helps customers understand the performance of our products. Our company's professionals can also provide appropriate product selection suggestions so that customers can purchase the right equipment.