Micron Range Programmable Dip Coater With Drying Oven

1. Micron range programmable dip coater adopts PLC program control and high-precision stepper motor drive, and the lifting operation is smooth and accurate.

2. Micron range programmable dip coater supports two modes: "single-pass operation" and "full-pass operation" to meet diverse experimental needs.

3. Micron range programmable dip coater can independently set the rising and pulling speed, the descending liquid entry speed, the immersion residence time, the drying time and the number of cycles to accurately control the coating process.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Introduction of micrometer grade programmable lab dip coater:

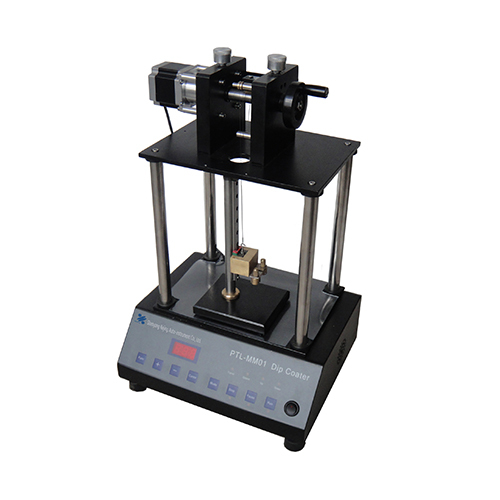

The PTL-UMB Micron-level Constant Temperature Pulling Coating Machine is a CE-certified product, specially designed by our company for dipping and pulling coating experiments in liquid-phase films. It is a precision pulling device with micron-level control, essential for research institutions and laboratories engaged in liquid-phase film growth studies.

This model adopts a PLC program control system to drive a high-precision stepper motor combined with the control actuators and pulling wires, ensuring smooth and precise lifting operations. By vertically immersing and pulling the samples, the device allows the samples to remain in the liquid-phase film material for a set period, resulting in the growth of a thin film of controlled thickness on the sample surface.

Two operation modes are available: Single-run and Full-run. The program allows independent setting of the sample’s upward pulling speed, downward immersion speed, dwell time in the liquid-phase film material, drying time, and the number of immersion/pulling cycles.

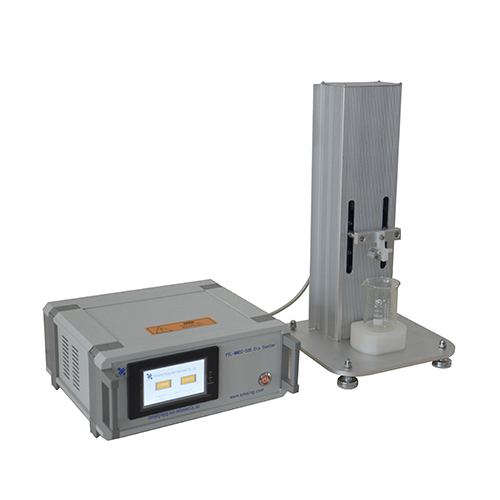

This programmable pulling coating machine features a constant-temperature heating type with an integrated heating and drying chamber. The temperature can be set according to the process requirements for film growth. The compact size, simple operation, and easy portability make it widely applicable in laboratories of universities, research institutes, and corporate R&D units.

Advantages of micron grade thermostatic dip coater:

1. Equipped with a 4.3-inch color touchscreen, the control interface is simple and intuitive, making it suitable for beginners.

2. This series of machines is compact and cost-effective, saving valuable laboratory space.

3. It adopts a PLC program-controlled high-precision stepper motor and uses suspended pulling wire transmission technology to reduce vibration during operation.

Technical parameters of micrometer grade programmable lab dip coater:

Product Name | PTL-UMB Micron Grade Thermostatic Dip Coater | |

Product Model | PTL-UMB | |

Installation Conditions | 1. Power supply: AC220V 50/60Hz; 2. Site environment: Use at a temperature of 25℃±15℃ and a humidity of 55%Rh±10%Rh. | |

Main Parameters (Specification) | 1. Working voltage of lifting machine: DC24V 3.75A (standard: AC100~240V power adapter) 2. Power of lifting machine: 50W. 3. Type: Program-controlled-constant temperature type (with constant temperature box). 4. Drive motor: high-precision stepper motor. 5. Speed setting range: 1-500um/s. 6. Dwell time: 1-999s. 7. Drying time: 1-999s. 8. Lifting stroke: 1-75mm. 9. Number of pulls: 1-20 times. 10. Effective immersion length: ≤60mm. 11. Upper limit of lifting load:≤100g. 12. Sample substrate size: 75mm×25mm×2.5mm (can clamp 2 pieces at the same time). 13. Display control: 4.3-inch color touch screen. 14. Constant temperature box parameters: · Working voltage: AC220V 50/60Hz. · Rated current: 3.6A. · Rated heating power: 0.8kW. · Temperature range: RT room temperature ~ +100℃. · Temperature control/setting method: digital tube double row PID/touch four buttons setting. · Heating operation timer: 0~9999 minutes or hours. · Inner dimensions (content volume): 310mm×310mm×310mm (30L). · Outer dimensions: 428mm×500mm×723mm. | |

15. Product specifications: · Dimensions: 428mm×500mm×995mm. · Weight: ≈50kg (including constant temperature box). |

| |

Standard accessories of film coating:

| NO. | Name | Qty | Image Link |

| 1 | Sample fixture | 1 set | -- |

| 2 | Loading cup | 1 pcs | -- |

| 3 | Raising wire | 3 items | -- |

Warranty:

One year limited with lifetime support (not including rusted parts due to inadequate storage conditions)

Logistics:

About us:

Shenyang Kejing's factory is located in Shenyang City, Northeast China, covering an area of 14,000 square meters. It integrates R&D, design, production, testing, packaging and after-sales service, and has a complete production chain. The production area is 2,818 square meters, with advanced equipment to efficiently produce high-quality products; the warehouse area is 2,908 square meters, ensuring adequate storage of finished products and raw materials and supporting efficient logistics management. Welcome to visit our factory!