Fully Automatic Multilayer Perovskite Spin Coating Machine

1. We have our own R&D technology and use professional skills in the field of film making.

2. The use process of Perovskite material coating machine adopts vacuum setting, which is safe and easy to operate.

3. Perovskite material coating machine has the characteristics of high precision. Welcome to contact or provide sample specimens.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Introduction of Perovskite spin coating machine:

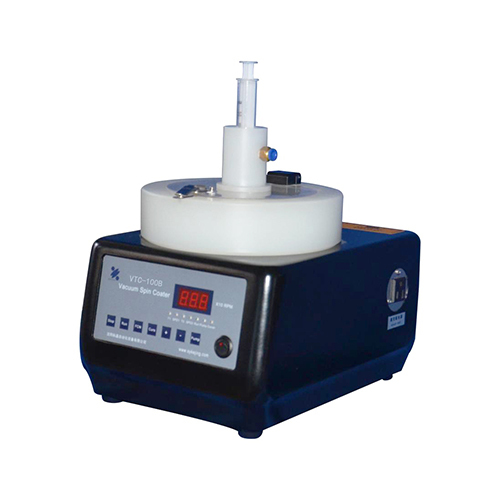

VTC-100ML Perovskite spin coating machine is suitable for coating of perovskite materials, surface coating processes such as semiconductors, crystals, optical disks, and plate making. This machine realizes the entire process of dripping glue, spin coating, and drying automatically; Perovskite spin coating machine can alternately coat two films at the same time, and the two liquids can alternate up to 500 times each, realizing the coating of thousands of layers of film. Perovskite spin coating machine can be used for coating preparation of acid and alkaline coating solutions. The equipment is equipped with vacuum suction cups of different sizes. Different vacuum suction cups can be selected according to the size of the sample, and the substrate is fixed by vacuum adsorption. Perovskite spin coating machine is mainly used in the laboratories of colleges and universities and scientific research institutes for the generation of thin films.

The main features of the fully automatic perovskite coating machine:

1. The fully automatic perovskite coating machine uses vacuum adsorption to fix the sample, which is easy to operate.

2. Different suction cups can be used according to the specifications of the sample, and the replacement is convenient and simple.

3. The motor of the fully automatic perovskite coating machine adopts a 24V DC brushless motor, which has high reliability, strong adaptability, simple repair and maintenance, low noise, small vibration, smooth operation, fast and stable start-up, and smooth operation after acceleration, which can ensure the consistency and uniformity of the coating thickness.

4. The fully automatic perovskite coating machine adopts an oil-free vacuum pump, which has the advantages of small size, simple structure, easy operation, convenient maintenance, and no pollution to the environment.

5. The cavity is made of polytetrafluoroethylene, which has a longer service life, chemical corrosion resistance and excellent stress cracking resistance; the body adopts a sheet metal structure, which is strong, durable and lightweight.

6. After heating, it can be cooled quickly by gas.

7. Chinese operating interface (full English operating system optional)

8. Fully automatic perovskite coating machine has a cover opening protection function. When the upper cover is opened during or after coating, the machine immediately slows down and stops.

9. The control interface of the perovskite material coating machine adopts touch screen control, which is simple and convenient to operate and intuitive to display.

10. Fully automatic coating process: the perovskite material coating machine can perform automatic glue dripping, automatic ventilation, automatic spin coating, and automatic drying.

11. Two liquids can be alternately coated, and up to 1,000 layers of film can be coated.

Parameters of Perovskite material coating machine:

Product name | VTC-100ML Fully Automatic Multilayer Perovskite Spin Coating Machine | |

Product model | VTC-100ML | |

Installation conditions | 1. Temperature and humidity: 10-85%RH (at 25℃ without condensation) Temperature: 0-45℃. 2. There is no strong earthquake source and corrosive gas around the equipment. 3. Water: sewage must be drained. 4. Electricity: single phase: AC220V 50Hz national standard three-pole socket 10A must be well grounded. 5. Gas: ① Sample tray: vacuum negative pressure (vacuum pump) exhaust flow rate is not less than 70L/M. ② Cooling: compressed gas or self-defined inert gas. 6. Workbench is recommended to be 1500X600X700mm and bear a load of more than 100KG (solid cement platform is best). 7. Ventilation device: no special requirements. | |

Main parameters | 1. Power supply for coating machine DC 24V 15A (with standard "power adapter"). | |

2. Power supply for dripper DC 24V 15A (with standard "power adapter"). | ||

3. Heating power supply Independent power supply: AC220V 50Hz. | ||

4. Total power ≤350W (excluding heating and external vacuum pump). | ||

5. Heating power 1350W. | ||

6. Heating temperature Maximum temperature: RT~200℃. | ||

7. Temperature control accuracy ±2℃. | ||

8. Heating method Radiation baking heating (carbon fiber heating tube). | ||

9. Control method PLC programmer + touch screen. | ||

10. Coating host cavity (material): polytetrafluoroethylene | ||

11. Sample tray (suction cup): polytetrafluoroethylene vacuum suction cup and aluminum suction cup: one set each (1 inch, 2 inches, 4 inches) (Please use polytetrafluoroethylene suction cup when heating, do not use aluminum suction cup due to fast heat conduction). | ||

12. Vacuum pressure display Electronic digital pressure sensor (digital vacuum pressure gauge) low pressure type: -100~100kPa. | ||

13. Coating operation mode Contains two groups of programs: A and B groups, each group can cycle up to 500 times, and each group of programs is divided into six sections. | ||

14. Coating speed 500~10000rpm (any integer setting, the minimum increment is 1rpm). | ||

15. Acceleration and deceleration rate Each section acceleration and deceleration setting range: 10~2000rpm (the increment is an integer multiple of 10). | ||

16. Speed stability ±1%. | ||

17. Feeding method: Dropper-precise quantitative dripping: with flat needle. | ||

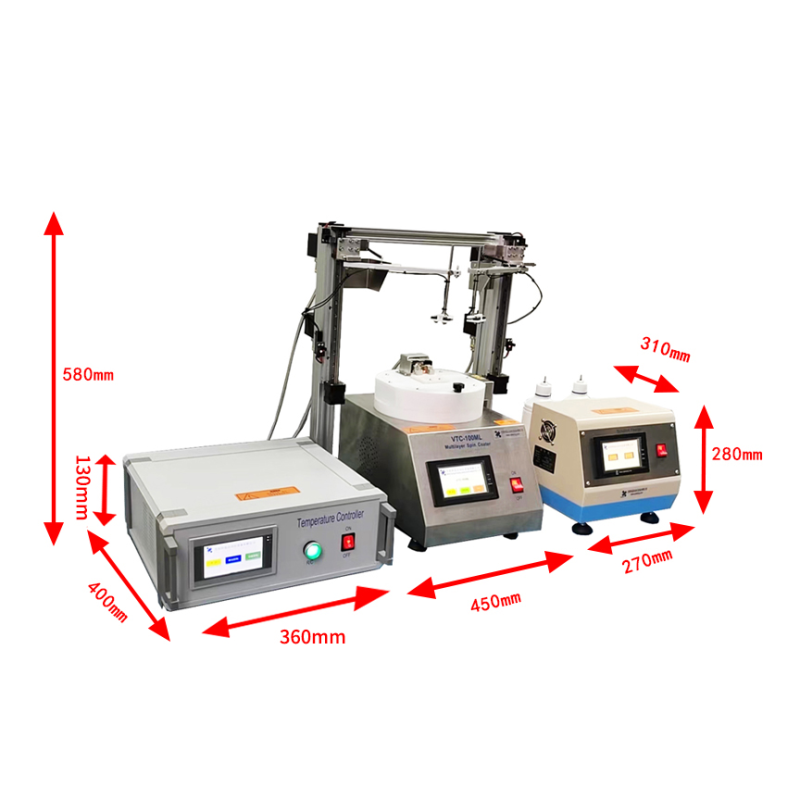

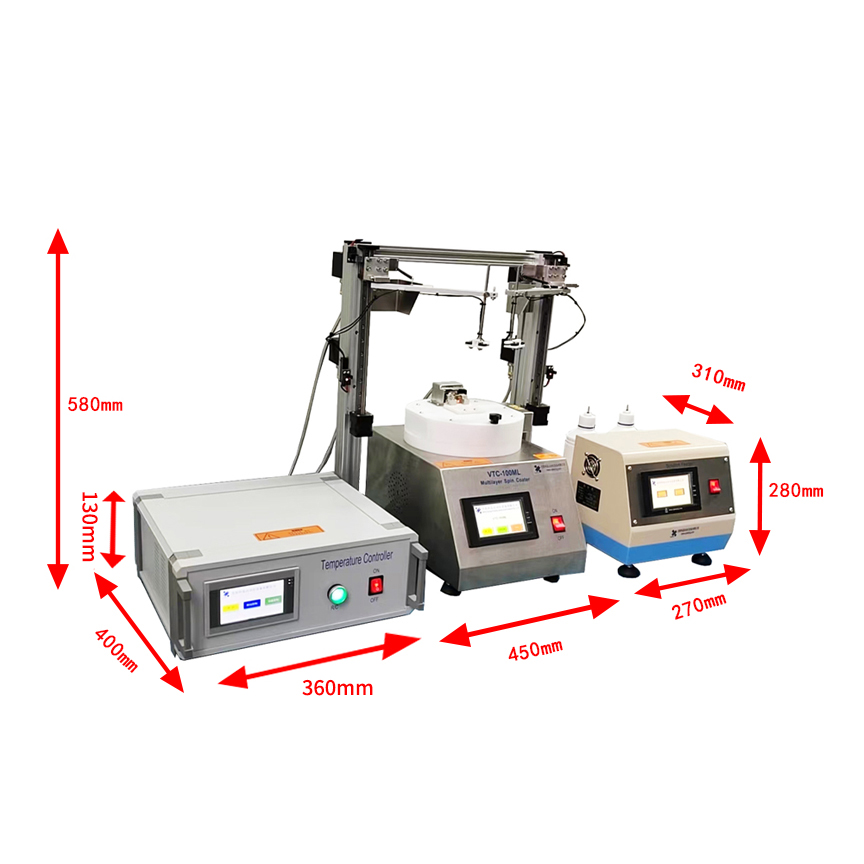

18. Product specifications: · Dimensions: Main unit: 450mmX400mmX580mm Heating control box: 360mmX400mmX130mm Drip feeder: 270mmX310mmX280mm · Weight: 40kg |  | |

Standard accessories of Perovskite material coating machine:

| NO. | Name | Qty | Picture |

| 1 | Vacuum suction cup (including O-ring) | 6 pcs (Ø25.4mm, Ø50.8mm, Ø101.6mm) |  |

| 2 | Center locator | 3 pcs | - |

| 3 | Glue syringe (20ml) | 2 pcs |  |

| 4 | Micro peristaltic pump | 1 set | - |

| 5 | Oil-free vacuum pump | 1 unit |  |

Standard accessories of Perovskite spin coating machine:

| NO. | Name | Function | Picture |

| 1 | Other sizes of vacuum cups | (optional) |  |

| 2 | Silent oil-free air compressor | (optional) |  |

Warranty:

One year limited with lifetime support (not including rusted parts due to inadequate storage conditions)

About us:

Our company has been deeply involved in the film making field for many years and has superb experience. At the same time, our company has a variety of equipment suitable for different materials to meet your various needs. We can also help you test the effect of the equipment. You can provide samples and we will prepare samples to let you see the effect of our products more intuitively. If you approve of our products, you can buy them and let you carry out your work more smoothly.