Flame Assisted Spray Pyrolysis Coating Equipment

1. Flame assisted spray pyrolysis machine is suitable for metal or ceramic materials, with flexible adaptability.

2. Flame assisted spray pyrolysis machine is developed by our own factory and has been certified by the industry.

3. Flame assisted spray pyrolysis machine can be controlled by software and is highly automated.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Introduction of Spray pyrolysis equipment:

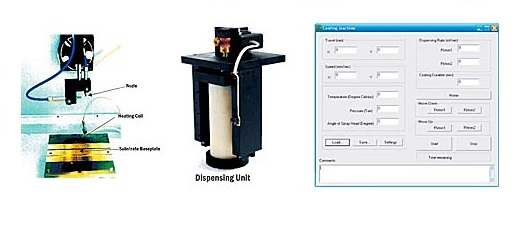

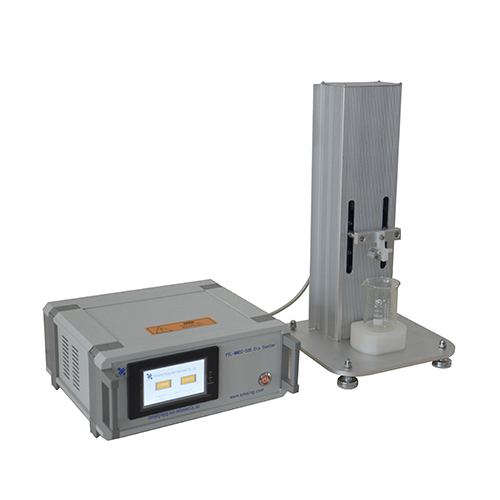

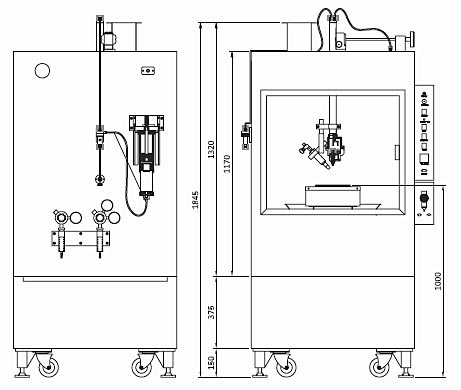

MSK-TH-04FA Flame assisted spray pyrolysis machine, spray glue machine is developed for the research of metal alloy and ceramic surface quality improvement, and is also suitable for the preparation of fuel cells. Spraying atomized solution on a heated substrate to obtain a deposited film, that is, forming a compound composition structure on the surface of the substrate. Before the spray is deposited on the substrate, it is heated by the flame generated by the oxidized liquefied gas mixture. This technology of spraying on a heated substrate through a liquefied gas flame, in addition to the required compounds being deposited at the deposition temperature, the products of other chemical reactions are volatile. Therefore, Spray pyrolysis equipment is generally used for depositing oxides on metal and ceramic substrates, and is particularly suitable for the deposition of Al2O3, ZnO, and the deposition of metastable solid solutions of ZnO-MgO and ZrO2-Y2O3 on amorphous silicon or nickel-based high-temperature alloys. The spray passes through the pre-combustion chamber and the nozzle under the action of a volumetric pump and compressed air. The substrate is placed on a heating table and the heating temperature is set by a dedicated controller. The heating table is placed on an XY moving platform and Spray pyrolysis equipment can move along a set trajectory during the coating process to obtain a uniform coating. The spray flow rate and substrate movement trajectory can be controlled by a personal computer, and the start and intensity of the flame are also controllable. In the absence of flame, the spray can be used for spray pyrolysis driven by compressed air. Therefore, a combination of flame-assisted and non-flame-assisted pyrolysis coating can be carried out on the same substrate in sequence.

Main features of Flame assisted coating machine:

1. Flame assisted coating machine has passed CE certification.

2. Spray pyrolysis equipment has equipped with air compressor

3. The Flame assisted coating machine uses software to centrally control parameters, which can control the injection pump, XY mobile platform, and drum collector. All parameters can be saved and restored for analysis or re-run.

4. The laptop of Spray pyrolysis equipment is pre-installed with software and can be used immediately.

Technical Parameters of Spray pyrolysis equipment:

Product name | MSK-TH-04FA Flame Assisted Spray Pyrolysis Coating Machine, Glue Spraying Machine | |

Product model | MSK-TH-04FA | |

Main parameters of Spray pyrolysis equipment | 1. Input power: AC 208V-240V single phase. | |

2. Solution injection: using stepper motor, propulsion speed 1ml/min-10ml/min, syringe unit capacity is 50ml or 250ml, injection pump can be controlled by laptop.

| ||

3. Nozzle: including 1 compressed air nozzle, maximum stroke of 100mm in X and Y axis, speed of 5mm/s-20mm/s in X axis, speed of 2mm/s-12mm/s in Y axis.

| ||

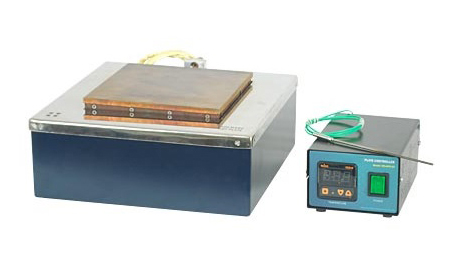

Heating plate: size is 150mm×150mm, maximum temperature is 500℃, equipped with RS232 computer interface.

| ||

Size of Flame assisted coating machine: Transportation size (two parts): 1423mm×1143mm×1778mm, 450kg; 1220mm×1016mm×915mm, 135kg |  | |

Notes of Flame assisted coating machine | The optimal process parameters can be explored from the following influencing factors: cleanliness, surface area, surface morphology and profile, temperature (heat), time (reaction rate, cooling rate, etc.), speed, physical and chemical properties, physical and chemical reactions. | |

About us:

We have advanced production equipment and strict quality management system, so that every product meets international standards. Our R & D team continues to innovate and is committed to improving product design based on market demand and customer feedback to provide more accurate and efficient solutions. With years of industry experience and technical accumulation, we have established a good reputation in the industry and won favorable comments from many customers.