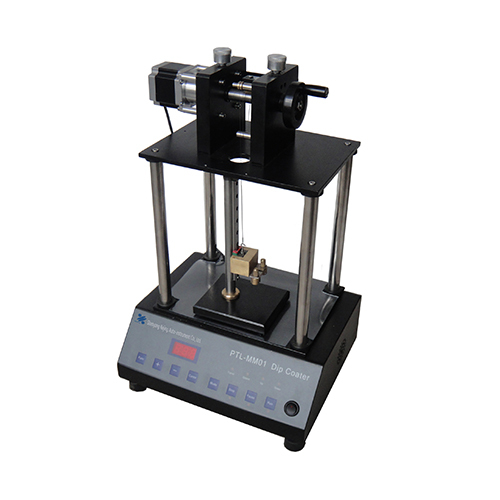

Dip Coater (1-200 mm/min) With Drying Oven Up To 100ºC

1.PTL-MMB01 constant temperature lifting coating machine is specially designed for the study of liquid epitaxial film.

2.Constant temperature lifting coating machine adopts a button-type control panel and a single-board computer to control the pulling speed of the wire to make the lifter run smoothly and accurately.

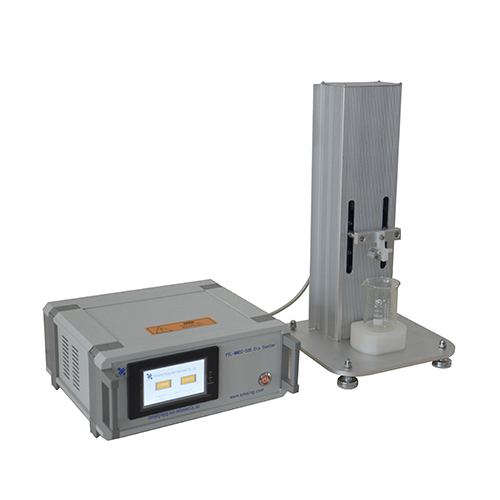

3.Constant temperature lifting coating machine can also be equipped with a thermostatic oven with a temperature of up to 100 ℃, so that the film growing process can be carried out at a constant temperature.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Introduction of constant temperature lifting coating machine:

PTL-MMB01 constant temperature dip coater with drying oven for R&D lab is a millimeter-level precision pulling equipment developed by our company for the study of liquid phase growth of thin films on substrates. It has passed CE certification and is a necessary product and equipment for liquid phase growth film research units and institutes.

The control system of constant temperature dip coater with drying oven for R&D lab is a self-developed high-precision single-chip control system that controls the operation of the actuator. The manual button switches the pulling direction. The lifting and lowering speed and stroke can be set. The lifting process runs smoothly and accurately. PTL-MMB01 constant temperature dip coater with drying oven for R&D lab pulls the sample vertically through cable drawing, immerses the sample in the liquid phase thin film material for a period of time and then pulls it out, so that a certain thickness of film grows on the surface of the sample. Constant temperature dip coater with drying oven for R&D lab can immerse the sample in the liquid thin film material through manual control and then automatically pull it back. It can also immerse the sample in the liquid thin film material through automatic control and manually pull it back. This machine is equipped with a constant temperature drying oven with a temperature of up to 100°C, which can ensure that the film growth process is carried out at a constant temperature. This series of machines are small in size, simple to operate and easy to carry, and are widely used in laboratories of colleges, research institutes and corporate units.

Advantages of constant temperature programmed dip coating machine:

1. Constant temperature programmed dip coating machine can provide a stable constant temperature dip coating environment.

2. The whole process of dip coating is carried out in a constant temperature field, which is conducive to film formation and curing.

3. Constant temperature programmed dip coating machine is simple and convenient to operate and clean, suitable for beginners.

4. Constant temperature programmed dip coating machine is small in size, cost-effective, and saves laboratory space.

5. Constant temperature programmed dip coating machine adopts high-precision stepper motor drive and wire conduction pulling technology for vibration reduction.

Technical parameters of constant temperature lifting coating machine

Product Name | PTL-MMB01 Constant Temperature Lifting Coating Machine | |

Product Model | PTL-MMB01 | |

Installation Conditions | 1. Power supply: AC220V 50/60Hz ; 2. Site environment: Use at a temperature of 25℃±15℃ and a humidity of 55%Rh±10%Rh. | |

Main Parameters (Specification) | 1. Working voltage of lifting machine: DC24V, 3.75A (with standard "power adapter") 2. Power of lifting machine: 50W. 3. Type: normal temperature type (with constant temperature box). 4. Driving motor: high-precision stepping motor. 5. Speed setting range: 1-200mm/min. 6. Upper limit of sample slide bracket stroke: 75mm. 7. Effective immersion length:≤ 60mm. 8. Upper limit of lifting load: ≤ 100g. 9. Substrate size: 75mm×25mm×2.5mm. 10. Constant temperature box parameters: · Working voltage: AC220V 50/60Hz. · Rated current: 3.6A. · Heating rated power: 0.8kW. · Temperature range: RT room temperature~+100℃. · Temperature control/setting method: double-row digital tube PID/touch four-button setting. · Heating operation timer: 0~9999 minutes or hours. · Inner dimensions (content): 310mm×310mm×310mm (30L). · External dimensions: 428mm×500mm×723mm. | |

11. Product specifications: Dimensions: 428mm×500mm×995mm. Weight: ≈50kg (including constant temperature box). |

| |

Standard accessories :

| NO. | Name | Qty | Image Link |

| 1 | Sample fixture | 1 set | -- |

| 2 | Loading cup | 1 pcs | -- |

| 3 | Raising wire | 3 items | -- |

Warranty:

One year limited with lifetime support (not including rusted parts due to inadequate storage conditions).

Logistics:

About us:

We provide customers with a full range of high-quality services throughout the entire process of pre-sales and after-sales. Before sales, our customer service team will provide professional product selection suggestions and recommend suitable products based on customer needs. After sales, we provide comprehensive technical support, including remote installation and commissioning guidance and maintenance suggestions, to help customers successfully complete their projects. We strive to make you feel at ease and satisfied in every link.