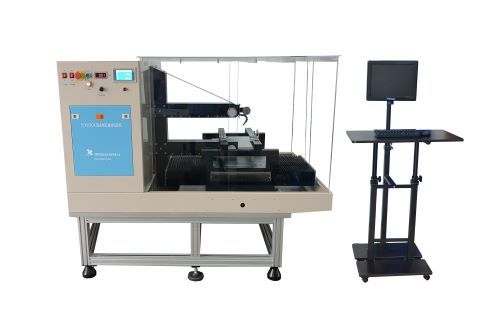

Diamond Wire Saw For Cutting Various Shapes Max.400mm Square

1. Adaptive Shape Cutting Wire Saw stands out for its advanced computer-aided drawing system that allows precise cutting of any 2D shapes.

2. The Adaptive Shape Cutting Wire Saw ensures high precision and efficiency in cutting operations.

3. The Adaptive Shape Cutting Wire Saw is built with brand new technology and has strong compatibility.

- Shenyang Kejing

- Shenyang, China

- 22 working days

- 50 sets

- Information

Product Description:

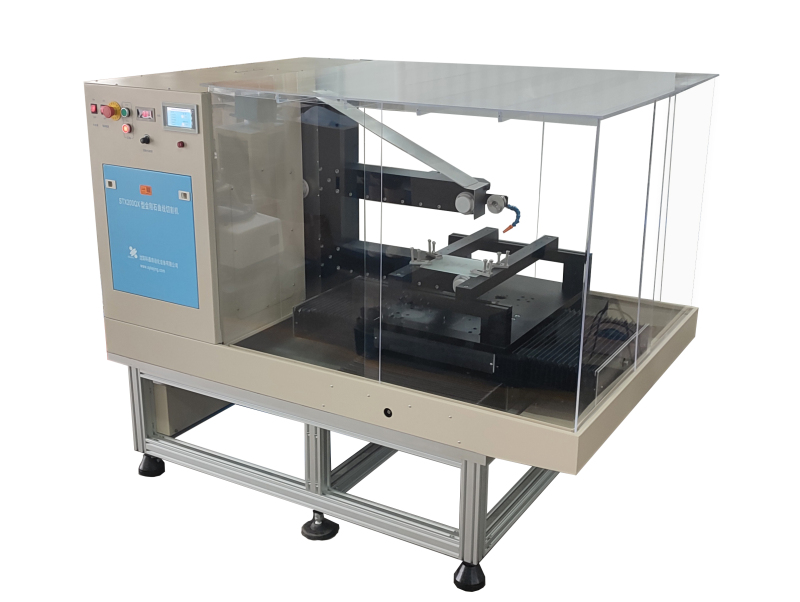

STX-200QX Complex Profile Diamond Wire Saw is the first equipment in our company that uses diamond wire to cut non-metallic materials of irregular shapes. The Complex Profile Diamond Wire Saw can set the cutting shape through computer drawing, and then the diamond wire travels according to the path set by the drawing, thereby cutting out various shapes. The Complex Profile Diamond Wire Saw effectively solves the problem of special-shaped cutting of some difficult-to-process materials for tensile tests, such as ceramics, crystals, glass, metals, composite materials, rocks, thermoelectric materials, infrared optical materials, composite materials and biomedical materials.

The Complex Profile Diamond Wire Saw inputs the shape of the material to be cut through drawings. It not only can cut round and I-shaped materials, but also can cut any 2D graphics such as plane, ellipse, fan, various symmetrical and asymmetrical 2D graphics etc. It can cut slice materials as well as thicker materials.

Freeform Cutting Diamond Wire Saw Technical Parameters:

Product Name | STX-200QX Freeform Cutting Diamond Wire Saw |

Freeform Cutting Diamond Wire Saw Model | STX-200QX |

| Installation Conditions | 1. Freeform Cutting Diamond Wire Saw Temperature and humidity: 10-85%RH (at 25℃ without condensation) Temperature: 0-45℃. 2. There is no strong vibration source and corrosive gas around the Freeform Cutting Diamond Wire Saw. 3. Power supply: single phase: AC220V 50Hz, national standard three-pole two-position socket 10A, the front end of the socket has a 16A air switch, and a good grounding wire must be provided 4. Air source (compressed air): ≥0.6Mpa 5. Coolant: required (strongly recommended to use --- cutting oil) 6. Workbench: no requirement 7. Ventilation device: no special requirements |

Freeform Cutting Diamond Wire Saw Major Parameters (Specification) | 1. Power supply interface: National standard three-pole socket with insurance AC220 50Hz 10A 2. Adaptive Shape Cutting Wire Saw Total power: 600W 3. Adaptive Shape Cutting Wire Saw Main body structure: aluminum alloy frame + sheet metal closed shell + acrylic protective cover 4. Diamond wire length: ≤230m 5. Diamond wire diameter: φ0.35-0.45mm 6. Diamond wire tensioning method: pneumatic tensioning system 7. Adaptive Shape Cutting Wire Saw Spindle cutting rotation method: reciprocating rotation 8. Adaptive Shape Cutting Wire Saw Spindle drive motor: AC frequency conversion AC220V 370W 9. Adaptive Shape Cutting Wire Saw Spindle speed: 15m/s adjustable 10. X-axis effective travel: ≤400mm 11. Y-axis effective travel: ≤400mm 12. X-axis, Y-axis running speed: effective value: 0.06-6mm/min (100 steps/second) 13. X-axis, Y-axis positioning accuracy: 0.01mm 14. X-axis and Y-axis drive motors: precision stepper motors 15. Upper limit of the inner spacing between the upper and lower guide wheels: ≤200mm 16. Sample clamping stage size: 530x690mm 17. Upper limit of sample cutting size: 400x400x100mm 18. Upper limit of sample cutting thickness: 100mm 19. Control mode: PLC programmer + 4.3-inch touch screen + CNC programming wire cutting control system 20. CNC programming display + control mode: 15-inch display screen, mouse + keyboard input 21. Safety control device: winding drum overtravel, wire breakage automatic stop, emergency stop switch Remarks: The Curve Cut Diamond Wire Saw is powered by domestic standard AC220V 50Hz power supply. The actual power supply is subject to the parameters on the rear label of the Curve Cut Diamond Wire Saw. |

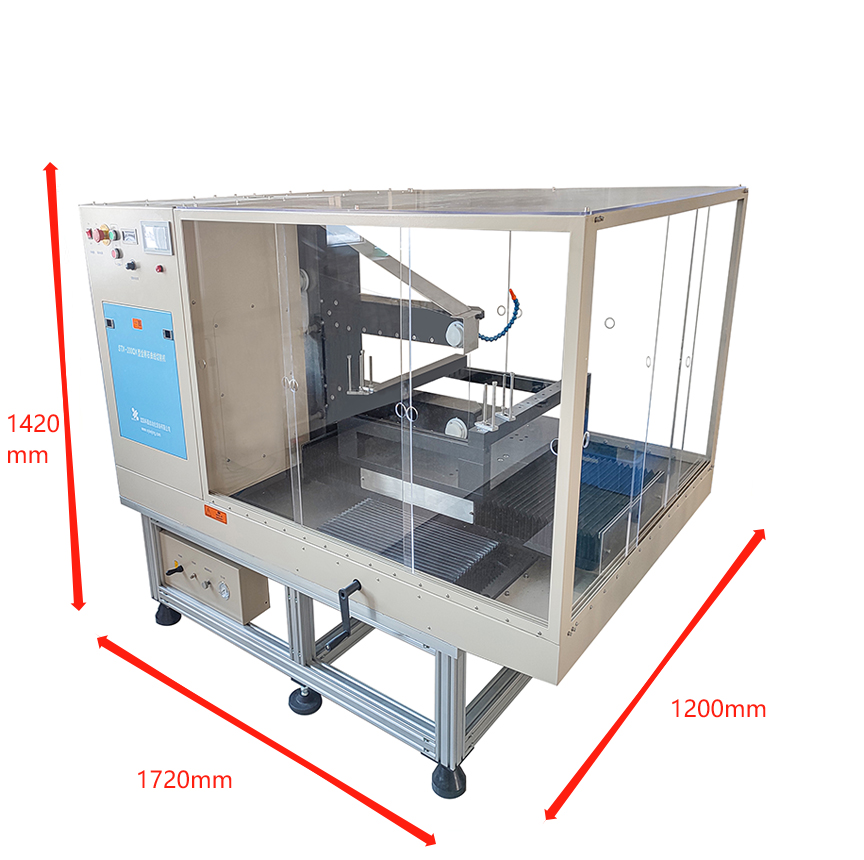

Freeform Cutting Diamond Wire Saw Dimension | Curve Cut Diamond Wire Saw Dimension: 1450mm(L)×1400mm(W)×1600mm(H) Curve Cut Diamond Wire Saw Net weight ≈ 575Kg

|

Functions and Applications | 1. Ceramic materials: alumina ceramics, zinc oxide ceramics, zirconium oxide ceramics, target ceramics, honeycomb ceramics, semiconductor ceramics, conductive ceramics, non-conductive ceramics, etc.; 2. Crystal materials: graphite, silicon crystals (solar polysilicon, single crystal silicon), sapphire, alumina crystals, infrared glass crystals, aluminum oxide crystals, silicon carbide crystals, cesium iodide crystals, etc.; 3. Glass materials: chalcogenide glass, optical glass, quartz glass, infrared glass, glass tubes, etc.; 4. Metal materials: iron, aluminum, copper, titanium alloy, magnesium alloy and other metals and alloys, non-ferrous metals (zinc sulfide, ferrite), etc.; 5. Composite materials: PVC board, carbon fiber composite materials, glass fiber composite materials, etc. 6. Rock materials: natural rocks, jade, meteorites, Pei Cui, agate, etc. precision cutting; Precision slicing of various high-value materials; geological light slices, geological thin slices (sedimentary rocks, igneous rocks, metamorphic rocks, ores), etc. slicing. 7. Thermoelectric materials: bismuth telluride, lead telluride, silicon-germanium alloy, etc. 8. Infrared optical materials: zinc selenide, zinc sulfide, silicon, germanium and other crystals 9. Biomedical materials: Bioplastic specimen slices (human and animal organs, jaw soft and hard tissue joint slices, implant observation, dental crowns and bridges, teeth and other histological specimens); Orthopedic soft and hard tissue joint slices (femur, hip joint, vertebral body and other living tissue and hard tissue, bone histological samples with implants, etc.); Cardiovascular stent slices, stone slices and other medical tissue slices; ...... Note: Materials with a hardness less than diamond wire can be precisely cut. |

Curve Cut Diamond Wire Saw Standard Accessories:

No. | Name | Quantity | Image link |

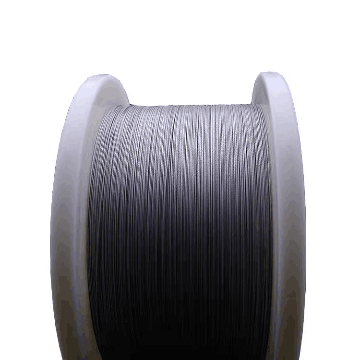

| 1 | Diamond wire φ0.35mm 230m/roll | 3 rolls |  |

| 2 | Diamond wire φ0.35mm 2500m/roll | 1 roll |  |

| 3 | Paraffin stick | 4 pieces |  |

| 4 | Oilstone strip | 1 piece |  |

| 5 | Frosted leather polishing pad (without adhesive backing) | 1 piece |  |

| 6 | Cooling cuttingoil | 3 barrels |  |

| 7 | STX-2500/100QX/200QX electric threader | 1 set |  |

Curve Cut Diamond Wire Saw Optional Accessories:

No. | name | functional type | picture |

1 | STX-100QX 3D precision fixture | (optional) |

|

Warranty

· One year limited with lifetime support (not including rusted parts due to inadequate storage conditions)

Logistics:

About Us:

SHENYANG KEJING AUTO-INSTRUMENT Co., Ltd., established in May 2000, upholds the motto of "practical, dedicated, hard-working, teamwork, credible, innovative, responsible, customer first high-quality products, advanced services." Committed to providing exceptional products and services to customers worldwide, the company has consistently aimed to lead in the field of material analysis equipment since the introduction of its first SYJ-150 Low Speed Diamond Saw. Shenyang Kejing's core mission is to serve society with innovative technology and prioritize customer-centered service.