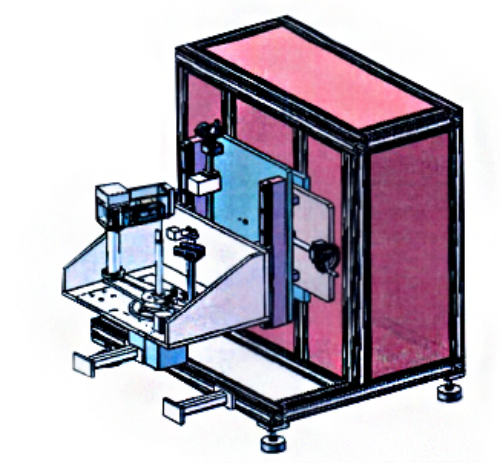

Crystal Directional Cutting All-in-one Machine

1. Diamond wire cutting saw employs high-precision cutting technology.

2. Diamond wire cutting saw has low cutting loss.

3. Diamond wire cutting saw features strong stability.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Product Introduction:

The automated diamond wire cutting saw is primarily used for precision cutting of material analysis samples. This system combines a diamond wire cutting machine with an X-ray orienting instrument. The Y-axis of the diamond wire cutting machine can be programmatically controlled to enter the orienting instrument in parallel and is equipped with a sample stage that can rotate 360 degrees horizontally to meet the position requirements of the crystal within the orienting instrument. After the crystal is oriented, the connected Y-axis then moves it back to the cutting equipment, avoiding the cutting angle errors caused by secondary clamping. This allows for quick orientation and cutting.

Product Advantages:

1. High precision diamond wire cutting machine is suitable for precision cutting of brittle, easily dissociated crystals.

2. In terms of material selection, the high precision diamond wire cutting machine uses aluminum profiles, which are characterized by their attractive appearance and lightweight construction.

3. With an automated design, the high precision diamond wire cutting machine can perform cutting tasks according to the programmed dimensions, saving time and effort.

4. In terms of technology, the application of new technology enables the high precision diamond wire cutting machine to achieve high-precision cutting of brittle materials.

5. The cutting wire of the high precision diamond wire cutting machine operates in a single-wire, continuous reciprocating motion mode, enhancing the efficiency of the cutting process.

Technical Specifications:

Product Name | Automated Diamond Wire Cutting Saw | ||

| Product Model | STX-620 | ||

Main Parameters | Diamond Wire Cutting Machine Section | ||

1. Power Supply Interface: National standard with fuse three-pin socket AC220 50Hz 10A 2. Total Power: 350W 3. Main Structure: Aluminum alloy frame 4. Diamond Wire Length: ≤150m 5. Diamond Wire Diameter: φ0.25-0.45mm 6. Diamond Wire Tensioning Method: Adjustable pneumatic tensioning 7. Tension Pressure Adjustment Range: 0.1-0.4Mpa 8. Spindle Cutting Rotation Mode: Reciprocating rotation 9. Spindle Drive Motor: AC variable frequency + reducer AC220V 300W 10. Spindle Speed: 5m/s adjustable 11. Z-axis Worktable Effective Travel: ≤160mm (subject to the actual machine) 12. Y-axis Worktable Effective Travel: ≤480mm 13. Z, Y Axis Feeding Accuracy: 0.01mm 14. Sample Table: Electric three-dimensional rotary table, horizontal 0-360° 15. Angle Table: Electric: ±15° 16. Y-axis, Z-axis, R-axis Drive Motor: Precision stepper motor 17. Maximum Distance Between Inner Sides of Two Guide Wheels: ≤180mm 18. Maximum Cutting Workpiece Diameter and Length: Φ150mm X 150mm 19. Worktable Center Load Capacity: ≤10Kg 20. Control Method: PLC programmer + 4.3-inch touchscreen 21. Parameter Display Mode: Digital 22. Safety Control Device: Overtravel of wire spool, automatic stop for wire breakage, emergency stop switch 23. Product Specifications: · Dimensions: 640x700x1450mm · Weight: approximately 170kg | |||

| X-ray Crystal Orientation Instrument Atomic Curvature Analysis System V2.0 | |||

一、 Functional Overview: 1. This instrument is a multi-angle, multifunctional crystal orientation instrument used for: orientation of crystal ingot end faces. 2. The instrument supports multi-angle measurement. 3. No calibration required; manual loading and unloading of the material being tested. 4. Automatic adjustment of the θ axis and 2θ axis. 5. X-ray focal point adopts a mechanical contact-type pin. 6. HMI displays data. 7. Fault indication. 二、 Tested Crystal: | |||

| Serial Number | Item | Content (Specification, Parameters) | |

| 1 | Material | Monocrystalline | |

| 2 | Shape | Crystal rod | |

| 3 | Specification | Diameter less than 8 inches | |

| 4 | Tested Area | End face | |

| 三、 Technical Specifications | |||

Serial Number | Item | Content (Specification, Parameters) | |

1

| Worktable | The instrument has one workstation. | |

| 2 | Measurement Method | Manual loading and unloading of materials. | |

| 3 | Power Input | Single-phase AC 220V, 50Hz, with voltage fluctuations not exceeding ±10%. The power supply should be equipped with a single-phase three-core socket, and the wiring should comply with national standards, i.e., left zero, right live, and upper ground. | |

4

| X-ray Tube | Copper target, fan cooling, anode grounded. | |

| 5 | Tube Voltage | Maximum tube voltage is 30KV, full voltage closing. | |

| 6 | Tube | Current 0-1mA, continuously adjustable (exceeding 1mA may damage the X-ray tube). | |

| 7 | Total Power Consumption | The total power consumption of the machine does not exceed 1.2KW. | |

| 8 | Instrument Accuracy | ±30 seconds (measured against a quartz standard piece provided by the supplier on the 10ī1 face). | |

| 9 | Minimum | Reading 3 seconds. | |

| 10 | Calibration | No calibration required (machine remains calibrated after power off). | |

| 11 | Display Mode | PLC touch screen operation and display (in degrees and minutes/seconds formats). | |

| 12 | Measurement Angle Range | 2θ angle: 0~+104°, θ angle: 0°~+52°. | |

| 13 | Protection | Door interlock, EMO, high voltage interlock, temperature control protection. | |

| 14 | Measurement Space | φ300*300mm. | |

| 15 | Receiver | Receiver B. | |

| 四、 Environmental Requirements: | |||

| Serial Number | Item | Content (Specification, Parameters) | |

1 | Power Supply | Single-phase AC 220V, 50Hz, with voltage fluctuations not exceeding ±10%. | |

| 2 | Outlet | The power supply should be equipped with a single-phase three-core socket, and the wiring should comply with national standards, i.e., left zero, right live, and upper ground. | |

| 3 | Ambient Temperature | Ambient temperature of +5~+35°C. It is recommended to use it at a constant temperature, preferably installed in an air-conditioned room (large temperature variations may affect measurement accuracy). | |

4 | Ambient Humidity | Relative humidity must not exceed 65%. | |

| 5 | Grounding Device | There must be a good grounding device, and the grounding resistance should not be greater than 4Ω. | |

| 6 | Water Requirement | None | |

| 7 | Air Source Requirement | None | |

| 五、 Acceptance Criteria: | |||

Serial Number

| Item | Content (Specification, Parameters) | |

| 1 | Precision Detection | Measurement is based on the standard quartz piece 10ī1 face provided by the seller. The equipment is tested using the standard quartz piece 10ī1 face, with an instrument accuracy of ±30 seconds, a microammeter drop of ±2 small divisions, and a minimum reading of 1 second. | |

| 2 | Repeatability Precision | Measure repeatability precision, with over 98% within the accuracy range. | |

Product Application:

The automated diamond wire cutting saw is widely used in the precision manufacturing field for producing various high-precision sensors and performing precise cuts on crystal materials. With its efficient and accurate cutting technology, the automated diamond wire cutting saw provides high-quality cutting services during the manufacturing process of high-precision measuring instruments, ensuring measurement accuracy.

The automated diamond wire cutting saw is extensively applied across industries requiring high precision and quality crystal processing, showing more significant advantages in fields with stringent technical requirements.

Our Services:

Our products are recognized by many customers for their performance, consistent quality, and long-term durability. We have a professional technical team that can provide customers with comprehensive service support in product selection, installation and commissioning, operation training, and other aspects. No matter what problems you encounter during the usage process, we will strive to offer you timely and effective solutions to ensure your production line operates efficiently and stably. Choosing us means opting for a dual guarantee of quality and service.