Cold Mounting Machine

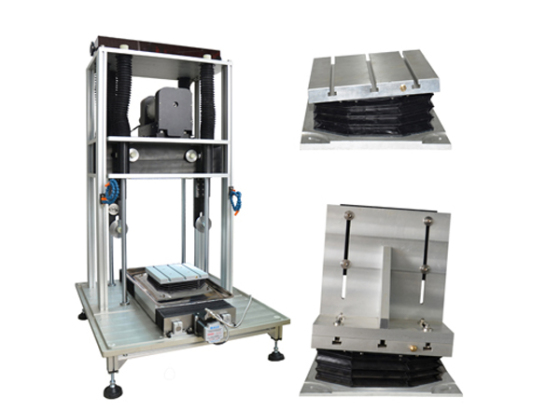

1. The vacuum cooling mounting press machine is compact and occupies little workbench area, making it easy to flexibly arrange in laboratories and production sites.

2. The vacuum cooling mounting press machine can mount multiple samples at the same time, improving work efficiency and saving time.

3. The vacuum technology of the vacuum cooling mounting press machine can effectively remove air from the pores of the sample and improve the mounting quality.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Introduction of vacuum cold mounting machine:

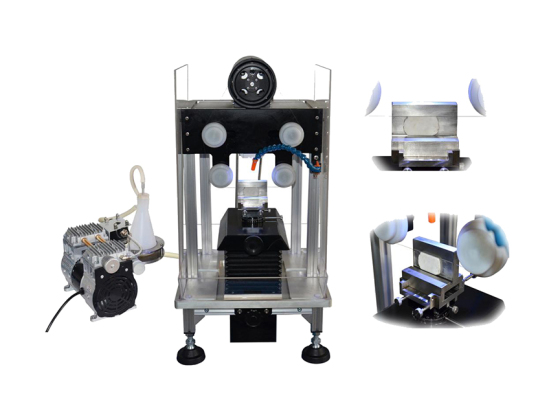

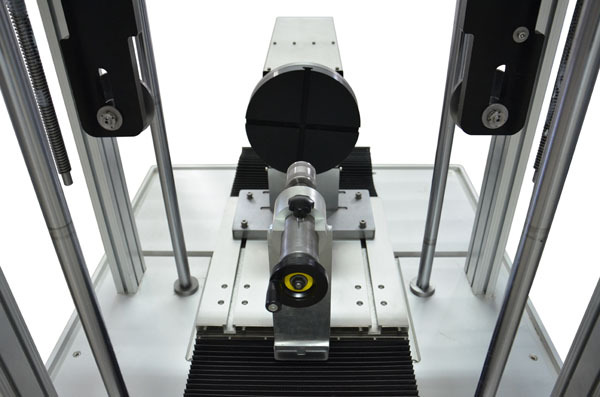

CXQ-2500 vacuum cold mounting machine is mainly used for cold mounting of various samples, especially for materials that are not suitable for hot mounting, circuit boards, materials with micropores, loose geological samples, etc. The working principle of vacuum cold mounting machine is simple, the equipment is compact, and it does not need to occupy a large area of the workbench. It can mount multiple samples at a time, and the size and shape of the mounted samples can be adjusted through different mounting molds. In industry, vacuum cold mounting machine can also be used in conjunction with dyes to inspect various defects in workpieces. The principle of vacuum cold mounting machine is to suck air out of the pores of the sample by vacuuming, and then use the atmospheric pressure to press the mounting material or dye into the micropores. After being cured by the curing agent for a certain period of time, it can solidify into a certain shape.

Advantages of metallographic vacuum cold mounting machine:

1.Metallographic vacuum cold mounting machine supports cold mounting of various samples, especially suitable for circuit boards, microporous materials and loose geological samples.

2.Metallographic vacuum cold mounting machine can detect various defects in workpieces and improve the quality of workpieces when used with dyes.

3.Metallographic vacuum cold mounting machine adopts environmentally friendly packaging to reduce pollution to the environment.

4.Metallographic vacuum cold mounting machine is simple to operate and easy to maintain.

Technical parameters of vacuum cooling mounting press machine:

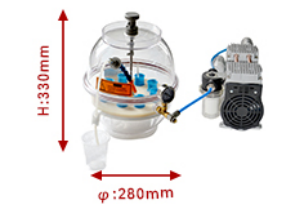

Product name | CXQ-2500 Vacuum Cold Mounting Machine |

Product model | CXQ-2500 |

Installation conditions | 1. Temperature and humidity: 10-85%RH (at 25℃ without condensation) Temperature: 5-45℃. 2. There is no strong vibration source and corrosive gas around the equipment. 3. Cooling water: No requirement. 4. Gas source: Vacuum pump: vacuum upper limit -700mmHg (-91KPa), air flow upper limit 7.2m³/h. 5. Ventilation device: Good ventilation environment, no special ventilation device requirements |

Main parameters | 1. Sample rotating disk diameter: About Ø230mm. 2. Upper limit of vacuum degree: ≤-0.08MPa (1Kg/cm2=0.1MPa). 3. Sample rotating disk rotation method: Manual. |

| Product specifications | Product specifications: Dimensions (tank): Outer diameter Φ280mm, height 330mm. Weight: 2.5kg.

|

Standard accessories:

| NO. | Name | Qty | Picture |

| 1 | Rotating disc | 1 set | -- |

| 2 | Liquid inlet pipe | 10 pieces | -- |

| 3 | Oil-free pump | 1 unit | -- |

| 4 | Mosaic mold | 6 pieces | -- |

| 5 | Material cup | 5 pieces | -- |

| 6 | Stirring stick | 5 pieces | -- |

Applications of vacuum cooling mounting press machine:

1. Material science: Used for cold mounting of various material samples, especially samples that need to maintain the original characteristics of the material, such as ores, ceramics, etc.

2. Electronic manufacturing: Suitable for mounting of circuit boards, and can protect sensitive electronic components under low temperature conditions.

3. Geological exploration: For geological samples with micropores, such as rocks and minerals, vacuum cooling mounting press machine can provide a reliable mounting process for subsequent analysis.

About us:

Our company promises that the equipment we provide is brand new and unused, and fully meets the quality, specifications and performance requirements agreed in the contract. We also guarantee that, under the condition of correct installation, reasonable use and maintenance of the equipment, it can always maintain excellent performance during its service life, helping you achieve efficient production.