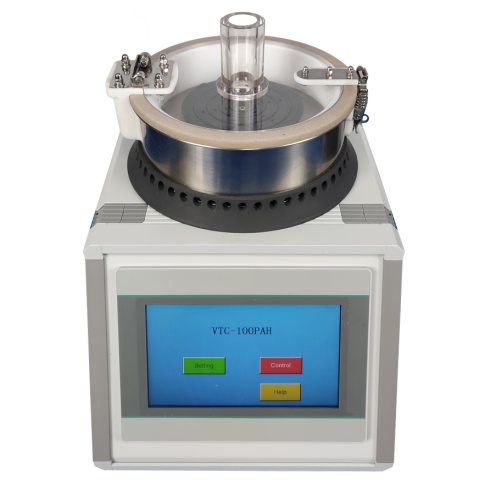

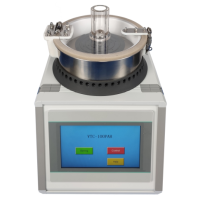

20000 RPM Ultra-Hi Speed Spin Coater

VTC-100PAH Vacuum Spin Coater is suitable for semiconductor process, crystal, optical disc, plate making and surface coating, etc. The sample is fixed by means of vacuum adsorption so that the samples can be taken and placed freely. The motor starts quickly and stably, which can ensure the consistency and uniformity of the coating thickness.

- Shenyang Kejing

- Shenyang, China

- 22 working days

- 50 sets

- Information

Product Introduction

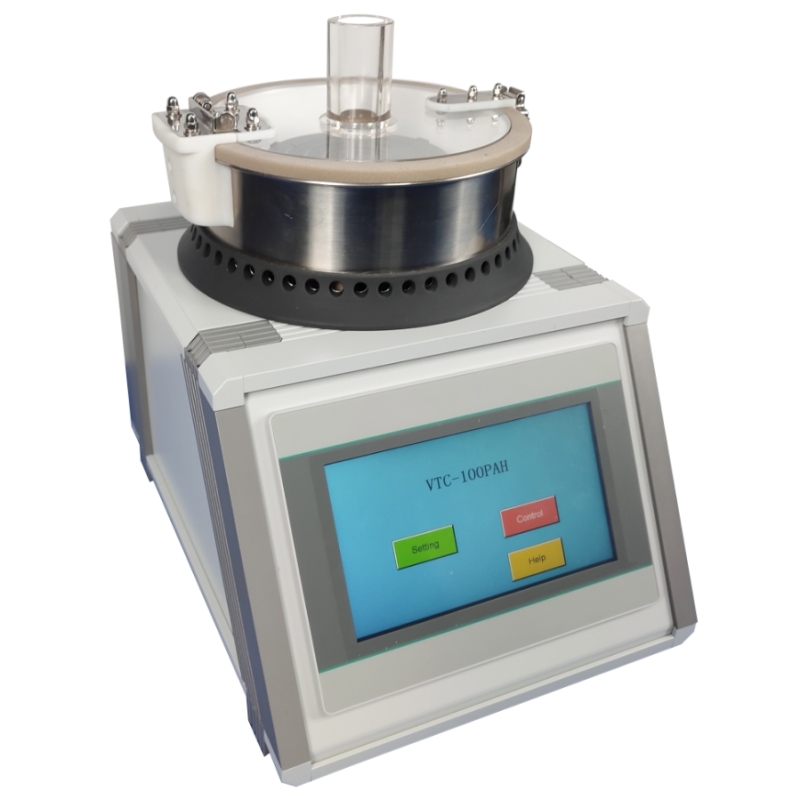

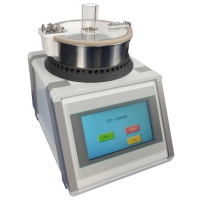

The VTC-100PAH Vacuum Spin Coater is designed for surface coating preparation in semiconductor processes, crystals, optical discs, and lithography applications. As a high-performance precision spin coater, the VTC-100PAH adopts an advanced design concept combined with a precise motion control system, enabling high-accuracy and high-uniformity spin coating operations.

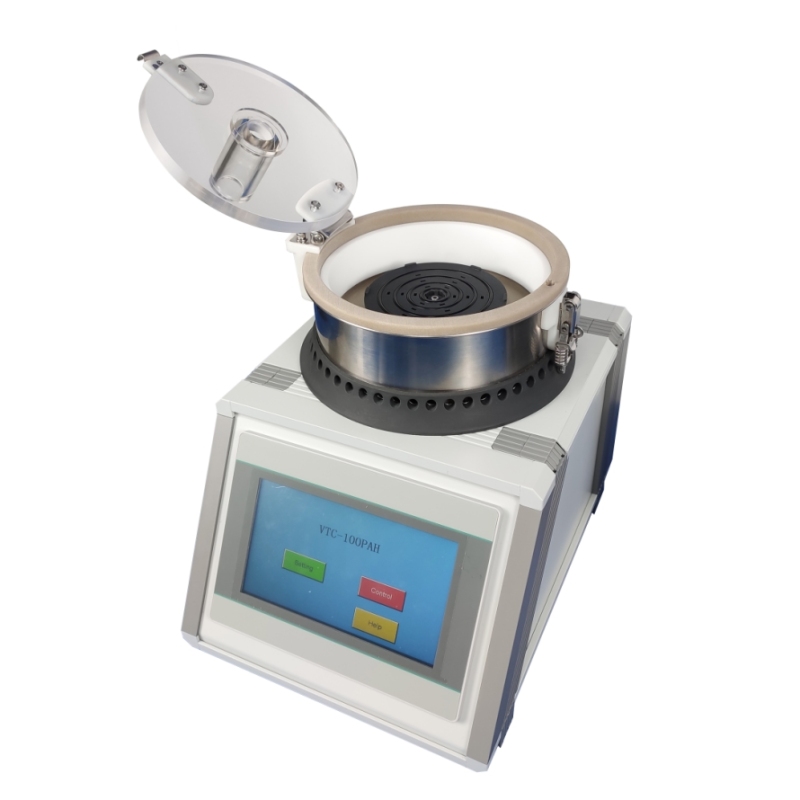

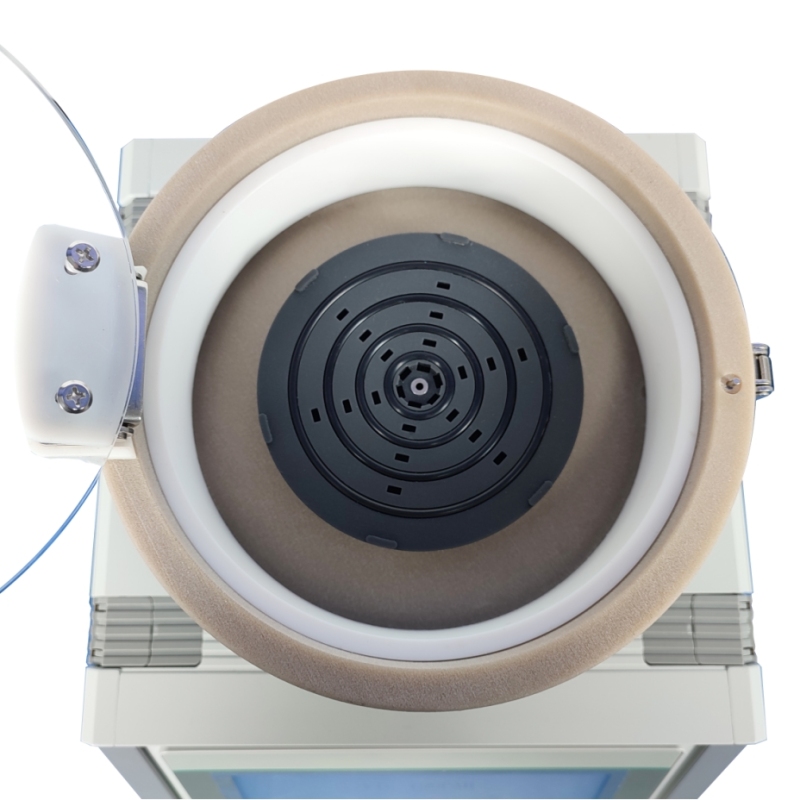

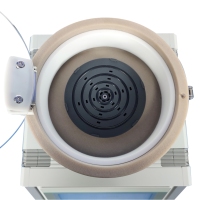

The chamber is made of polypropylene, featuring excellent heat resistance, electrical insulation, and high wear-resistance processing performance. The chamber itself cannot be vacuumed; instead, during operation, the vacuum chuck and gas pipeline are connected to an external vacuum pump, which firmly holds the sample on the substrate holder. This setup allows simple operation, easy sample loading and unloading, with the chuck vacuum reaching up to –0.08 MPa.

The rotating spindle is driven by a high-speed brushless DC motor, offering low noise, minimal vibration, smooth operation, high reliability, wide adaptability, and easy maintenance. The motor starts up quickly and runs stably after acceleration, ensuring consistent and uniform coating thickness.

With its simple operation, convenient cleaning, and compact design, the VTC-100PAH Vacuum Spin Coater is widely used in university and research institute laboratories for thin-film preparation.

Main Features:

1. The sample is fixed by means of vacuum adsorption, which is easy to operate.

2. The degree of vacuum can reach -0.08MPa.

3. Different chucks can be used according to sample specifications, and the replacement is convenient and simple.

4. High reliability, strong adaptability, simple repair and maintenance, low noise, small vibration, stable operation, fast and stable startup, stable operation after acceleration, and ensured consistency and uniformity of coating thickness

5. The oilless parallel-bar vacuum pump has the advantages of small size, simple structure, easy operation, convenient maintenance, and no environmental pollution.

6. The chamber is made of polypropylene material with longer service life to improve the resistance abilities of chemical corrosion and excellent stress crack, and the machine body adopts cast aluminum structure, which is durable and light in weight.

7. It has the functions of vacuum detection and open-cover detection, and the upper cover has a protection lock.

8. It has the function of open-cover protection. When the top cover is opened during the coating process or at the end of the coating, the machine immediately decelerates rapidly until it stops.

9. Chinese/English switchable operating system

10. The control interface adopts a touch screen, and the numerical display is more intuitive and reliable.

Technical Parameters:

Product Name | VTC-100PAH Vacuum Spin Coater | |

Product Model | VTC-100PAH | |

1. Temperature & Humidity: 10–85%RH (at 25℃, non-condensing); Temperature: 0–45℃. 2. Environment: No strong vibration sources or corrosive gases around the equipment. 4. Power Supply: AC100–240V, 50/60Hz 10A. 5. Air Supply: Vacuum negative pressure (vacuum pump) with a pumping speed of not less than 70 L/min. 6. Worktable: Recommended size 800 × 600 × 700 mm, load capacity ≥ 50 kg (a solid concrete table is preferred). 7. Ventilation: No special requirements. | ||

The main parameters | 1. Equipment power supply: DC24V Standard adapter: IN AC100-240V 50/60Hz OUT DC24V 15A 2. Power: 150W(External vacuum pump not included) 3. Main Chamber (Material): Polypropylene + Acrylic 4. Suction cup specifications: 2 inches, 4 inches 5. Operation program: contains 16 operation stages 6. Speed range: setting: 1500-20000rpm (incremental increment: 100rpm as a unit) 7. Each section increase rate setting range: 100 rpm—6000 rpm. 8. Deceleration and parking rate range: 100 rpm—3000 rpm. 9. Time range: 1-99s (set speed range: 1500 —10000rpm) 1-60s (set speed range: greater than 10000 — 20000rpm) 10. Vacuum interface: quick-connect connector, connected with φ8 PU tube. 11. Operation interface: 7-inch touch screen | |

Product Dimension and Weight | 12. Product Specifications · Dimension: 250mm×340mm×320mm · Weight: 12kg | |

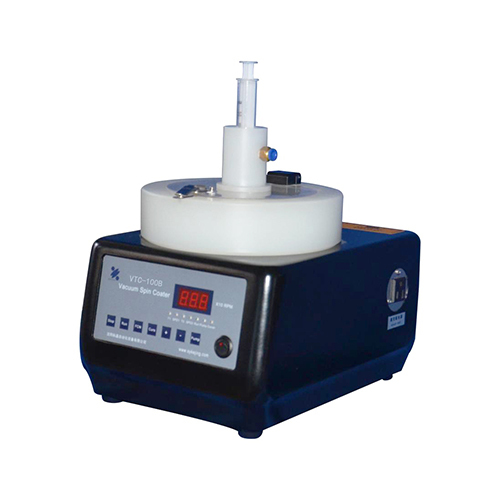

Standard Accessories:

| No. | name | qty | picture |

| 1 | Vacuum chuck (including O ring) (2 inches and 4 inches) | 2 pcs |  |

| 2 | Epoxy injector/syringe (20ml) | 1 pcs |  |

| 3 | Oilless vacuum pump | 1 pcs |  |

| 4 | Adapter 24V/15A | 1 pcs |  |

Optional Accessories:

| No. | name | functional type | picture |

| 1 | Vacuum chucks of other specifications | (optional) |  |

| 2 | Pipette (made in China) | (optional) |  |

| 3 | Pipette (imported) | (optional) |  |

Warranty:

One year limited with lifetime support (not including rusted parts due to inadequate storage conditions)

Logistics: