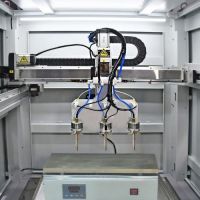

Ultrasonic Spray Pyrolysis Coating Machine

1. The automatic ultrasonic spray pyrolysis coater includes three ultrasonic spray heads (1 or 2 optional).

2. The automatic ultrasonic spray pyrolysis coater produces a fine droplet spray with an average size of 50 microns.

3. The x-y travel of the automatic ultrasonic spray pyrolysis machine is controlled by the touch screen outside the glove box.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Ultrasonic spray pyrolysis coater introduction:

GB-USP-14-3 is the largest ultrasonic spray pyrolysis coater system in the glove box, with a choice of one to three ultrasonic spray heads. Ultrasonic spray pyrolysis coater can deposit multilayer films on substrates up to 14 inches of coating area, with a maximum temperature of 250℃, suitable for the preparation of air-sensitive perovskite solar cells and fuel cell electrodes.

Advantages of ultrasonic spray pyrolysis machine:

1. Ultrasonic spray pyrolysis machine can cover a maximum coating area of 14 inches (X-Y MAX 360mm), suitable for multi-layer thin film deposition.

2. The heating platform temperature can reach up to 250℃.

3. Automatic ultrasonic spray pyrolysis coater is suitable for fluids with a viscosity range of 1-50mPa·s (cP) and supports coating of multiple materials.

Technical parameters of ultrasonic spray pyrolysis machine:

| Product Name | GB-USP-14-3 Ultrasonic Spray Pyrolysis Machine |

| Product Model | GB-USP-14-3 |

| Main Parameters | Power: Single-phase 208-240 volts AC voltage, 50/60Hz, single-phase 2500W. 1. Sprayer: · Includes three ultrasonic nozzles (optional 1 or 2). · Ultrasonic atomizing nozzle: 40kHz, 0-130W adjustable. · Produces fine droplet spray with an average size of 50 microns. · Fluid viscosity range: 1-50mPa·s (cP). · Sprayer lateral movement: X-Y MAX360mm. (14 inches x 14 inches). · Drive speed X axis (min-max): 10-800mm/s. · Y axis drive speed (min-max): 1-12mm/s. · Z direction can be adjusted manually. · X-Y stroke is controlled by the touch screen outside the glove box. 2. Pumping system: · Includes three digital syringe pumps for delivering solution to each nozzle. · Upper limit of syringe capacity: 200mL(three increments). · Pumping rate range: 1.963μL/min When using a syringe with an inner diameter of 50mm, Flow rate MIN is 294.524mL/min. 3. Heating plate: · Dimensions: 400mm×300mm. · Temperature limit: 250℃. · Digital temperature controller. 4. Glove box: · The ultrasonic spray system is located in a standard glove box with purification system. · Hinged door for easy access to the equipment. · Oxygen and humidity levels: <1ppm. 5. Control panel: · The touch screen control panel is located outside the glove box and can control parameters. · X-Y spray area and speed. · Heating plate temperature. · Injection speed of three injection pumps |

About us:

Our goal has always been to provide our customers with an excellent service experience, especially in logistics and packaging. In terms of packaging, we strictly select high-quality wooden boxes and follow strict standards to ensure that products are not damaged during transportation. The packaging team carefully inspects each product to ensure compliance with export requirements and reduce possible risks of damage during transportation.