Ultrasonic Spin Spray Coater

1. Plasma sputtering coater with 3 sputtering sources and glove box can replace different nozzles and adjust the height to achieve the best atomization surface

2. The nozzle of plasma sputtering coater with 3 sputtering sources and glove box has pneumatic assistance, which can effectively control the deposition of atomized solution particles in the designated area.

3. After you receive the automated ultrasonic spin spray coater, we also provide you with comprehensive sales services, such as remote guidance.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Introduction of lab ultrasonic spin spray coater:

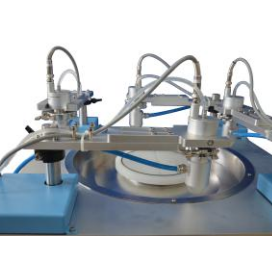

VTC-300USS-4 lab ultrasonic spin spray coater realizes automatic ultrasonic atomization coating by spraying on a plane with a reciprocating swing arm. The lab ultrasonic spin spray coater can realize fully automatic liquid injection pump to precisely control the liquid flow rate and achieve a uniform state on the spraying plane. It is widely used in education and research, as well as in fields related to the development of thin films for solar cells.

Advantages of aultrasonic spin spray coater:

1.Automated ultrasonic spin spray coater has two different operation modes: four ultrasonic nozzles work in sequence; four ultrasonic nozzles work together to meet different needs of users.

2.Automated ultrasonic spin spray coater uses computer program control, which is flexible and easy to operate.

3.The main shaft of the automated ultrasonic spin spray coater adopts a DC motor, which is high speed and low noise.

Technical parameters of lab ultrasonic spin spray coater:

| Product name | VTC-300USS-4 Lab Ultrasonic Spin Spray Coater |

| Product model | VTC-300USS-4 |

| Main parameters | 1. Spindle speed: 500-3000rpm. 2. Suction cup diameter: φ203 mm (8 inches). 3. Upper limit of substrate diameter: φ300 mm. 4. Swing arm: Working swing angle is 30° |

| Product specifications | 5. Product specifications: Dimensions: Equipment dimensions: 600×600×450 mm. Control box dimensions: 500×500×400 mm. |

Standard accessories:

| No. | Name | Qty | Pictuer |

| 1 | Host | 1 unit | -- |

| 2 | Control box | 1 unit | -- |

| 3 | Oil-free silent pump (30L) | 1 unit | -- |

| 4 | Oil-free vacuum pump | 1 unit | -- |

| 5 | Silicone tube | 4 sticks | -- |

| 6 | Vacuum silicone grease | 1 bottle | -- |

| 7 | PU blue tube Φ8 (1.5 meters) | 6 sticks | -- |

| 8 | Hexagon wrench (3mm, 4mm, 5mm, 6mm) | 1 each | -- |

| 9 | Syringe (20ml) | 4 sticks | -- |

Optional accessories:

| No. | Name | Function | Picture |

| 1 | Multi-channel (heatable) liquid supply system, drying device, etc. | (Optional) |

Our services:

Our products are recognized by many customers for their excellent performance, stable quality and long-term durability. We have a professional technical team that can provide customers with a full range of service support such as product selection, installation and commissioning, and operation training. No matter what problems you encounter during use, we will strive to provide you with timely and effective solutions to make your production line run efficiently and stably.

About us:

Shenyang Kejing Auto-instrument Co., Ltd. was established in May 2000 and is dedicated to serving the scientific research community and providing a wide range of materials analysis products. Its main products include cutting, grinding, polishing, coating, stirring, calendering, sintering, analysis equipment and related consumables. The company is committed to meeting the full range of sample preparation and analysis needs for various materials such as crystals, ceramics, metals, etc. Shenyang Kejing focuses on providing small-scale production for universities, research institutions and factories, and is committed to becoming a dynamic, trustworthy and respected company in the field of scientific instruments.